SassyGrass71

Well-Known Member

Ok, I just read this thread and it answered some of my questions.

http://www.forabodiesonly.com/mopar/showthread.php?t=234343

I will make sure the little blue box has a good ground and retest for spark.

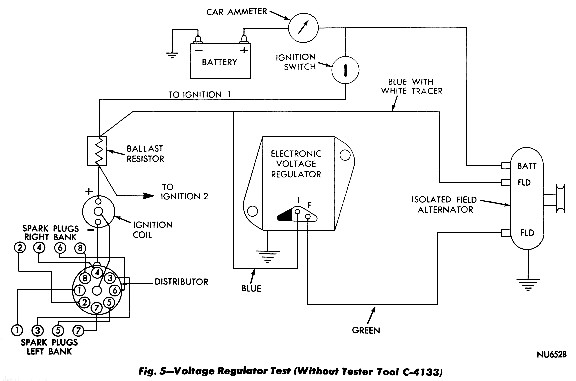

Here is what I have found with my latest purchase, someone put a later model 225 in and also converted it to electronic ignition. Here is a pic of my setup.

What I have found is that the two wires coming from the little blue box, and going to the distributer have no power when the key is on. Wires going into the little blue box both have power when the key is on.

Also, on the alternator are two spades that show 12v when keyed. Is this correct?

Last, the green wire that plugs into the one spade goes across and connects into the little silver box located to the left of the little blue box. That wire shows ground and does not change when it receives 12v from the alt. It feels like its shorting out. I get good voltage at the coil with this wire unplugged, and low voltage when its plugged in. Again, is this correct or is the little silver box bad. I will also clean up its grounds and check it again. Both boxes had rusty screws and contact points.

I hope my descriptions make sense, and again, thanks in advace for the help.

Sam

http://www.forabodiesonly.com/mopar/showthread.php?t=234343

I will make sure the little blue box has a good ground and retest for spark.

Here is what I have found with my latest purchase, someone put a later model 225 in and also converted it to electronic ignition. Here is a pic of my setup.

What I have found is that the two wires coming from the little blue box, and going to the distributer have no power when the key is on. Wires going into the little blue box both have power when the key is on.

Also, on the alternator are two spades that show 12v when keyed. Is this correct?

Last, the green wire that plugs into the one spade goes across and connects into the little silver box located to the left of the little blue box. That wire shows ground and does not change when it receives 12v from the alt. It feels like its shorting out. I get good voltage at the coil with this wire unplugged, and low voltage when its plugged in. Again, is this correct or is the little silver box bad. I will also clean up its grounds and check it again. Both boxes had rusty screws and contact points.

I hope my descriptions make sense, and again, thanks in advace for the help.

Sam