All issues sorted with the pump; wound up using the core from the '78 Lincoln with the piston from the '68 pump as-is (no shimming or other such modifications), though the vane is from the '78 as well. Housing remains the early '68 unit.

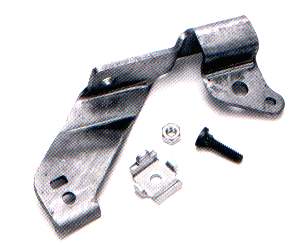

Fits nicely there on the '89 LA van bracket (only took two freakin' weeks). Still need to find a non-metric bolt for the top back bolt, which is presently a dual-ended stud.

I might hold off on doing the exhaust on this side and splurge on a Firm Feel steering gear. I want this car to be highway safe, and those stock PS boxes are probably the furthest thing from highway safe that I've ever known.

-Kurt

Fits nicely there on the '89 LA van bracket (only took two freakin' weeks). Still need to find a non-metric bolt for the top back bolt, which is presently a dual-ended stud.

I might hold off on doing the exhaust on this side and splurge on a Firm Feel steering gear. I want this car to be highway safe, and those stock PS boxes are probably the furthest thing from highway safe that I've ever known.

-Kurt