I have had my '68 340 Formula S FB Black on Black for 55 years come June. I finally got the restoration essentially complete and thought I should write up some of the background on the car and detail the history. So I wrote 32 pages with photos and want to share it with FABO members. I will copy and paste sections of the history so that the post isn't too long. Please comment and I will add or modify the story as appropriate.

Part 1 Background and Reminiscing

The Barracuda itself was/is a 1968 Fastback Formula S in black with a 340, A727, disk brakes, Sure Grip, 3.55 gears, AM radio, and a bench seat. Not much else.

The car was built on December 7, 1967, so it was only 18 months old and had 17,000 miles on it when I purchased it. It looked perfect, at least to me, but the owner said that it had been hit in the back by a PU truck which punched out the rear window. I could hardly tell that it ever was hit, but I was only 17 at the time. More on that later! The rear valance was a 318 single exhaust version which I was told was requested when the car was repaired after the accident. He had the exhaust dump in front of the axle and had flanges near the head pipe to remove the pipes when drag racing. I don’t recall if he ever said how fast the car was, but I was soon to find out.

I spent the summer learning the car and buying tools I would need to work on the car. I remember that I got a Sears Craftsman toolbox and large selection of tools for $25. Still a lot back then, but useful!

I needed to register the car, naturally, so I drove to the DMV for an emissions check and registration. Back then it was just a tailpipe sniff, so trivial. I remember the DMV office with smog check was in the port area so there were lots of businesses and few people on the road. The guy that did the smog check had a Nova (unknown engine or anything) and wanted to see how fast the Cuda was. We raced on a back street a few times and I beat him consistently, which was thrilling for a 17 year old kid.

Living in Hot Rod Heaven, SoCal, I had numerous drag strips available to me. I first went to Lion’s Drag Strip in the Wilmington area right next to Long Beach off Alameda Street. I actually met Big Willie and saw his Hemi Charger run a number of times. Big Willie was a 6’6” black guy that pulled kids off the street in Watts and showed them the joys of drag racing instead of street racing. He was a hero to those kids.

I began to try out other drag strips as Lion’s was not the most enjoyable place to race. I began to go to Orange County International Raceway (OCIR) most of the time as it was both well run and the ‘Cuda seemed to love that strip. On Wednesday evenings, I could get 6-10 or more runs in and practice my launch and reaction time skills. I kept all the timing slips in my glove compartment for a long time and at one point had 350 or more in there. Unfortunately, I didn’t keep them all but I still have 29 of the better runs. One cool Wednesday evening when the fog was coming in, I was able to make 10 runs all in the 13.60 to 13.50 second range at 103 to 104 MPH with the best time of 13.45 at 104.65. I even had a few 0.02 and 0.03 second reaction times. I sometime took notes on the competitor and one timing slip showed I raced a 1970 Coronet R/T with a 440 and 4.56 gears which ran a 13.61 against my 13.58. That was close.

By the end of my Senior year in HS, I had learned a lot how to drive the Cuda. The last day of class they let us out early and I took a girlfriend to lunch. On Woodruff Blvd, a wide street with a landscaped divider in the middle, I ran across “The Fastest Car In School”, a ’66 Nova SS 283 stroked to a 301 with a 4sp and 4.11 gears. There was no one on the road at that point so we raced from a stop. He spun and I scooted leaving him in the dust. He came up and said that it wasn’t a fair race because I had 4.56 gears (he assumed, as he lost), so he wanted to go from a roll where he had the advantage (so he thought). Well, that wasn’t so as I had 3.55 gears and was in the power band of the 340. No contest. That was the end of him being the Fastest Car in HS, but only for a day as we graduated that night.

Most times I raced the ‘Cuda, I took the back seat out which weighs about 50 lbs as it is the fold down seat, put a few gallons of Chevron Supreme White Pump 102 octane fuel in the tank, and headed off to the track. I sometimes dropped the exhaust but that was a pain to do at the track and really didn’t make that much difference anyway. The car had H70-14 rear tires that were retreads of Goodyear tires. A local tire shop in Bellflower had tire retreading equipment and it was cheaper than buying new tires. Plus he used a soft compound that had a lot more traction than the Firestons E70-14’s that were stock on the car. Traction is everything as I was becoming aware.

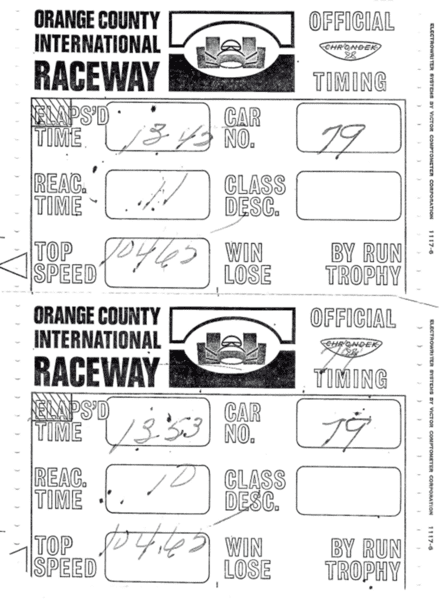

Figure 1 Selection of the fastest timing slips I saved.

In the late ‘60’s and early ’70’s, Camaro and Chevelle SS 396’s were very popular and just about everywhere. I had loads of fun running against them as the almost always spun their tires off the line and I simply throttled through the launch with little tire spin. Game Over. They generally turned away embarrassed to have lost to a small block Mopar. I did learn how fast a SS 396 375 HP Nova was when I punched off against my Brother-in-Law on the street from a roll once (Yes, I know!). We were neck to neck to about 60 when I backed off having shown that the 340 could match a Nova SS 396. My BIL didn’t mention that ever again. He worked for a speed shop (Super Shops in Downey, CA) a that time and had lots of upgrades done to the 396 like headers and a 850 DP, but still was just as fast as a stock 340. Ooops.

I went to Irwindale Raceway as well, but more often on Saturdays. One Saturday during a NHRA race, I registered and the put me in F Stock Automatic. I was the only one in that class so I got a trophy. During time trials, I ran against a new 1970 Cuda 440+6. We were neck and neck going into the first speed timing light when I nudged him by ½ a length and won that race. The engine was missing at the time so I went to the pits to change plugs. The ‘Cuda 440+6 owner came up saying that he had never been beat and wanted to see my Hemi. Ooops, his mouth fell open when he saw a small block in the engine compartment and simply walked away. That was enjoyable to say the least!

I drove the ‘Cuda all over the place and had 60,000 miles on it by 1971 and had about 350 timing slips at that point. I was in College at the time (Long Beach State University). The ’73 gas crisis hit and insurance costs were rising quickly, and I was working less and studying more, so I first got a 90 CC Kawasaki then a 500 CC Suzuki to go to school and work in. The Cuda sat in a garage for a number of years. When I was in Graduate School at UC Irvine, I needed wheels again, so I rebuilt the engine with a mild cam from a 318 but kept the Carter AVS and tuned it to perfection. I put 2.94 gears in the rear and was able to eke out 23-24 MPG from the ‘Cuda.

I was a graduate student in chemistry at UCI and in 1976 we had an American Chemical Society conference in San Fracisco. I drove there taking a number of other grad students with me. On the way home, I filled up in San Jose near where my sister lived and drove all the way to Irvine on one tank of gas traveling about 379 miles on less than 16 gal. I was on fumes but made it to a gas station, so I got just less than 24 MPG. That was impressive for the time. I did take the car to OCIR with that setup and turned 14.50’s at 95, which for 2.94 gears and a mild cam was fast enough.

After graduation, I moved to NorCal and worked for Chevron in the lubricants area. The Cuda was used only sparingly as I purchased a ’66 Hemi Belvedere with 16,000 miles on it and took that to shows. I also got a ’67 383 FS 4SP FB ‘Cuda for $500 which was a lot considering it was apart with the engine in the trunk and the transmission in the back seat. I spent a lot of time restoring that ’67 and it was a nice car when done, but I had to sell it when I moved to a new home due to CCR’s that wouldn’t let me park it in my driveway. I got $6,500 for it, which is what I had into the restoration, so I was OK with that, but now I really wish I had that car and the Belvedere too. But at least I kept my ’68 ‘Cuda!

Job changes and moves left me little time to work on the ‘Cuda but I did get the car running finally when in Tulsa, OK. I had 3 engines for the car and built 2 of them for myself and built one for a friend with a ’67 Barracuda convertible 273 that we were slowly turning into a Formula S 340. I gave him the original engine as it was +0.040 at the time and the other two were +0.20 which at the time was a better deal to me. I got the car running but it needed a lot of other work to be nicely done. The rear quarters had a lot of damage from both the original owner’s accident and subsequent hits. I must have had 5 coats of paint on the car at that time and some was flaking off. I moved to Denver area in 2007 and began to drive the Cuda occasionally but longed to restore it.

Part 1 Background and Reminiscing

Background and Reminiscing

I purchased my first car, a 1968 Plymouth Barracuda, on 6 June 1969. I was a Junior in Lakewood High School at the time and this was the last day of classes. I walked about 2.5 miles from school to the home of the then current owner who was a stock clerk at a grocery store where I was a box boy earning $1.85/hr. I saved most of my money to buy this car and borrowed some from my father. I purchased the car for $1700 plus $100 for the Crager’s that were on it already. The owner said that I could have the original wheels on the car but it looked too good with Crager’s to pass up the opportunity to purchase them even though it was 50 hours of work time. Boy how times have changed. Gas was $0.20/gal for regular and my father was appalled that the car took Premium, which was $0.25/gal. What a waste of money!The Barracuda itself was/is a 1968 Fastback Formula S in black with a 340, A727, disk brakes, Sure Grip, 3.55 gears, AM radio, and a bench seat. Not much else.

The car was built on December 7, 1967, so it was only 18 months old and had 17,000 miles on it when I purchased it. It looked perfect, at least to me, but the owner said that it had been hit in the back by a PU truck which punched out the rear window. I could hardly tell that it ever was hit, but I was only 17 at the time. More on that later! The rear valance was a 318 single exhaust version which I was told was requested when the car was repaired after the accident. He had the exhaust dump in front of the axle and had flanges near the head pipe to remove the pipes when drag racing. I don’t recall if he ever said how fast the car was, but I was soon to find out.

I spent the summer learning the car and buying tools I would need to work on the car. I remember that I got a Sears Craftsman toolbox and large selection of tools for $25. Still a lot back then, but useful!

I needed to register the car, naturally, so I drove to the DMV for an emissions check and registration. Back then it was just a tailpipe sniff, so trivial. I remember the DMV office with smog check was in the port area so there were lots of businesses and few people on the road. The guy that did the smog check had a Nova (unknown engine or anything) and wanted to see how fast the Cuda was. We raced on a back street a few times and I beat him consistently, which was thrilling for a 17 year old kid.

Living in Hot Rod Heaven, SoCal, I had numerous drag strips available to me. I first went to Lion’s Drag Strip in the Wilmington area right next to Long Beach off Alameda Street. I actually met Big Willie and saw his Hemi Charger run a number of times. Big Willie was a 6’6” black guy that pulled kids off the street in Watts and showed them the joys of drag racing instead of street racing. He was a hero to those kids.

I began to try out other drag strips as Lion’s was not the most enjoyable place to race. I began to go to Orange County International Raceway (OCIR) most of the time as it was both well run and the ‘Cuda seemed to love that strip. On Wednesday evenings, I could get 6-10 or more runs in and practice my launch and reaction time skills. I kept all the timing slips in my glove compartment for a long time and at one point had 350 or more in there. Unfortunately, I didn’t keep them all but I still have 29 of the better runs. One cool Wednesday evening when the fog was coming in, I was able to make 10 runs all in the 13.60 to 13.50 second range at 103 to 104 MPH with the best time of 13.45 at 104.65. I even had a few 0.02 and 0.03 second reaction times. I sometime took notes on the competitor and one timing slip showed I raced a 1970 Coronet R/T with a 440 and 4.56 gears which ran a 13.61 against my 13.58. That was close.

By the end of my Senior year in HS, I had learned a lot how to drive the Cuda. The last day of class they let us out early and I took a girlfriend to lunch. On Woodruff Blvd, a wide street with a landscaped divider in the middle, I ran across “The Fastest Car In School”, a ’66 Nova SS 283 stroked to a 301 with a 4sp and 4.11 gears. There was no one on the road at that point so we raced from a stop. He spun and I scooted leaving him in the dust. He came up and said that it wasn’t a fair race because I had 4.56 gears (he assumed, as he lost), so he wanted to go from a roll where he had the advantage (so he thought). Well, that wasn’t so as I had 3.55 gears and was in the power band of the 340. No contest. That was the end of him being the Fastest Car in HS, but only for a day as we graduated that night.

Most times I raced the ‘Cuda, I took the back seat out which weighs about 50 lbs as it is the fold down seat, put a few gallons of Chevron Supreme White Pump 102 octane fuel in the tank, and headed off to the track. I sometimes dropped the exhaust but that was a pain to do at the track and really didn’t make that much difference anyway. The car had H70-14 rear tires that were retreads of Goodyear tires. A local tire shop in Bellflower had tire retreading equipment and it was cheaper than buying new tires. Plus he used a soft compound that had a lot more traction than the Firestons E70-14’s that were stock on the car. Traction is everything as I was becoming aware.

Figure 1 Selection of the fastest timing slips I saved.

In the late ‘60’s and early ’70’s, Camaro and Chevelle SS 396’s were very popular and just about everywhere. I had loads of fun running against them as the almost always spun their tires off the line and I simply throttled through the launch with little tire spin. Game Over. They generally turned away embarrassed to have lost to a small block Mopar. I did learn how fast a SS 396 375 HP Nova was when I punched off against my Brother-in-Law on the street from a roll once (Yes, I know!). We were neck to neck to about 60 when I backed off having shown that the 340 could match a Nova SS 396. My BIL didn’t mention that ever again. He worked for a speed shop (Super Shops in Downey, CA) a that time and had lots of upgrades done to the 396 like headers and a 850 DP, but still was just as fast as a stock 340. Ooops.

I went to Irwindale Raceway as well, but more often on Saturdays. One Saturday during a NHRA race, I registered and the put me in F Stock Automatic. I was the only one in that class so I got a trophy. During time trials, I ran against a new 1970 Cuda 440+6. We were neck and neck going into the first speed timing light when I nudged him by ½ a length and won that race. The engine was missing at the time so I went to the pits to change plugs. The ‘Cuda 440+6 owner came up saying that he had never been beat and wanted to see my Hemi. Ooops, his mouth fell open when he saw a small block in the engine compartment and simply walked away. That was enjoyable to say the least!

I drove the ‘Cuda all over the place and had 60,000 miles on it by 1971 and had about 350 timing slips at that point. I was in College at the time (Long Beach State University). The ’73 gas crisis hit and insurance costs were rising quickly, and I was working less and studying more, so I first got a 90 CC Kawasaki then a 500 CC Suzuki to go to school and work in. The Cuda sat in a garage for a number of years. When I was in Graduate School at UC Irvine, I needed wheels again, so I rebuilt the engine with a mild cam from a 318 but kept the Carter AVS and tuned it to perfection. I put 2.94 gears in the rear and was able to eke out 23-24 MPG from the ‘Cuda.

I was a graduate student in chemistry at UCI and in 1976 we had an American Chemical Society conference in San Fracisco. I drove there taking a number of other grad students with me. On the way home, I filled up in San Jose near where my sister lived and drove all the way to Irvine on one tank of gas traveling about 379 miles on less than 16 gal. I was on fumes but made it to a gas station, so I got just less than 24 MPG. That was impressive for the time. I did take the car to OCIR with that setup and turned 14.50’s at 95, which for 2.94 gears and a mild cam was fast enough.

After graduation, I moved to NorCal and worked for Chevron in the lubricants area. The Cuda was used only sparingly as I purchased a ’66 Hemi Belvedere with 16,000 miles on it and took that to shows. I also got a ’67 383 FS 4SP FB ‘Cuda for $500 which was a lot considering it was apart with the engine in the trunk and the transmission in the back seat. I spent a lot of time restoring that ’67 and it was a nice car when done, but I had to sell it when I moved to a new home due to CCR’s that wouldn’t let me park it in my driveway. I got $6,500 for it, which is what I had into the restoration, so I was OK with that, but now I really wish I had that car and the Belvedere too. But at least I kept my ’68 ‘Cuda!

Job changes and moves left me little time to work on the ‘Cuda but I did get the car running finally when in Tulsa, OK. I had 3 engines for the car and built 2 of them for myself and built one for a friend with a ’67 Barracuda convertible 273 that we were slowly turning into a Formula S 340. I gave him the original engine as it was +0.040 at the time and the other two were +0.20 which at the time was a better deal to me. I got the car running but it needed a lot of other work to be nicely done. The rear quarters had a lot of damage from both the original owner’s accident and subsequent hits. I must have had 5 coats of paint on the car at that time and some was flaking off. I moved to Denver area in 2007 and began to drive the Cuda occasionally but longed to restore it.