brewil

Well-Known Member

Hey everyone....

Coming at you from South Africa

So I purchased a B-body A833 and a 65 tail housing and shaft which the shop here has made into a beautiful combo for my A-body without using a ball and grunion setup - so engineering is great!

HOWEVER!!!

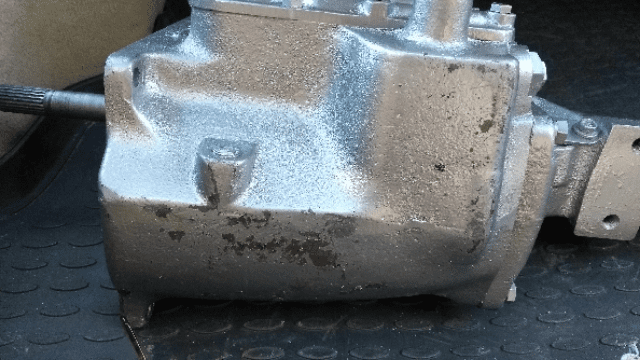

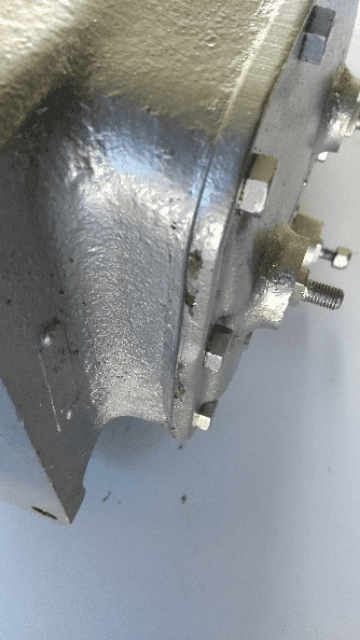

They insisted on painting the entire trans after assembly (over grease and grime and silicone), over all the bolts including the bell housing side mating face.

I purchased a Brewers Rebuild kit but hey...Why use the proper gaskets when they can just silicone between the tail and main case, Inspection Cover and main case.

So now I don't know how much of the kit they've used, especially if they ditched the gaskets in favour of silicone. I have asked to return the box, for them to take it apart, and I will have the cases cleaned and painted and they can re-assemble.

Now the issue is:

How can I check if they've used the parts from the kit - bear in mind that they took everything off the B-Body Main Shaft and re-installed on the '65 A-Body Main shaft.

INCOMPETENCE drives me insane.

The pics are taken the day they painted the thing.

Do you guys clean and paint the cases before assembly or after???

Coming at you from South Africa

So I purchased a B-body A833 and a 65 tail housing and shaft which the shop here has made into a beautiful combo for my A-body without using a ball and grunion setup - so engineering is great!

HOWEVER!!!

They insisted on painting the entire trans after assembly (over grease and grime and silicone), over all the bolts including the bell housing side mating face.

I purchased a Brewers Rebuild kit but hey...Why use the proper gaskets when they can just silicone between the tail and main case, Inspection Cover and main case.

So now I don't know how much of the kit they've used, especially if they ditched the gaskets in favour of silicone. I have asked to return the box, for them to take it apart, and I will have the cases cleaned and painted and they can re-assemble.

Now the issue is:

How can I check if they've used the parts from the kit - bear in mind that they took everything off the B-Body Main Shaft and re-installed on the '65 A-Body Main shaft.

INCOMPETENCE drives me insane.

The pics are taken the day they painted the thing.

Do you guys clean and paint the cases before assembly or after???