Yeah that's like mine. I hate to do that to my new one, because it's so purdy and black anodized. lol But what the hell, right? That's hot roddin. But you know.......if we had Chevys, their cables would slip right in.Took a die grinder with a 1/8" wheel to it. It came with a 1/16" slot.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Allstar Performance ALL54224 Throttle Cable Bracket

- Thread starter hunt2elk

- Start date

-

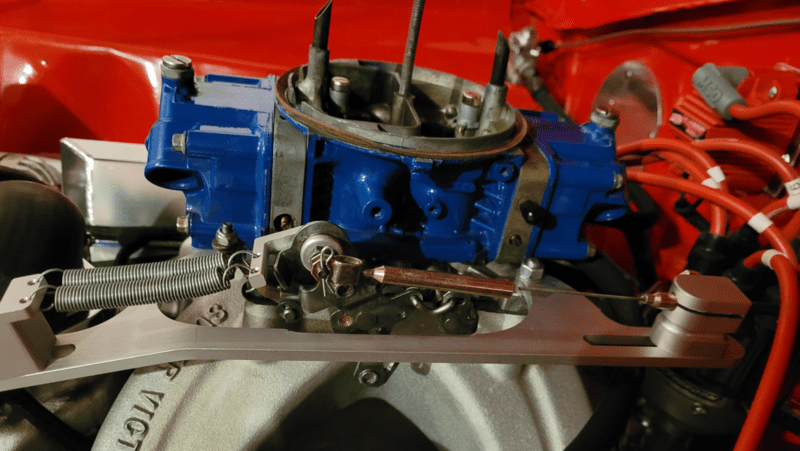

I checked all my old paperwork and indeed I am using that exact same AllStar bracket #54224 as you have. So to try to better help, I went out to the garage and took a couple better pics. I've got a side shot and an overhead shot (don't mind those blue powder-coated carb parts - it was a used carb!). As far as difficulty in getting the cable into the slot and sawing it open wider, I'm not sure what you mean. I just used a little screwdriver to pry it open a tad to get the cable started into the slot and then pulled it all the way in. Then I slid the metal casing into the hole from the back and positioned it where I needed it to get full 100% throttle and locked it down.

Here's the side shot. You can see where I have the cable positioned in the rear holder and where it attaches to the carb arm. I took the bushing that comes with the bracket, drilled a hole in it, and put my throttle cable stud through the bushing. A nut on the back side secures it all. Note I bent the front part of the bracket down to give a bit more clearance to my upper rad hose. I also tweaked one of the 2 springs to reduce the load. And that was it...it took some layout work and head-scratchin' but I've been happy with it since I installed it - have not had to touch it at all.

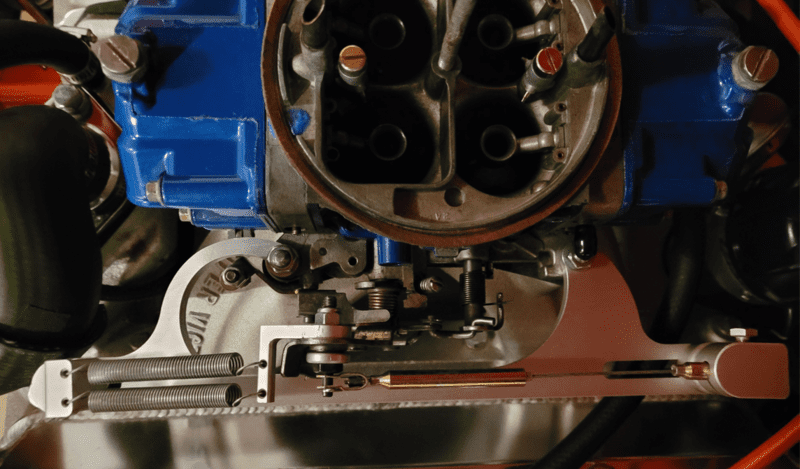

Here's an overhead shot.

Hope this helps and doesn't add confusion!!

Here's the side shot. You can see where I have the cable positioned in the rear holder and where it attaches to the carb arm. I took the bushing that comes with the bracket, drilled a hole in it, and put my throttle cable stud through the bushing. A nut on the back side secures it all. Note I bent the front part of the bracket down to give a bit more clearance to my upper rad hose. I also tweaked one of the 2 springs to reduce the load. And that was it...it took some layout work and head-scratchin' but I've been happy with it since I installed it - have not had to touch it at all.

Here's an overhead shot.

Hope this helps and doesn't add confusion!!

The difference between yours and @hunt2elk's bracket is, your cable is bare, while his still has the plastic casing. His bracket may have broken if he had tried to pry it open that far. With mine, imagine that bracket with no slot whatsoever, but just the small round hole in it. Useless as tits on a boarhog. So I removed it and cut a factory cable clamp off a factory bracket and bolted it onto aftermarket bracket. I had to play around with it to get full throttle, but I finally got it to work. It's just hot rodding. Bend this, cut that, grind this, drill that. Nothing much is made to bolt on a Mopar. Chevy guys got it made, but they're still driving stuff everybody else has. Screw that.I checked all my old paperwork and indeed I am using that exact same AllStar bracket #54224 as you have. So to try to better help, I went out to the garage and took a couple better pics. I've got a side shot and an overhead shot (don't mind those blue powder-coated carb parts - it was a used carb!). As far as difficulty in getting the cable into the slot and sawing it open wider, I'm not sure what you mean. I just used a little screwdriver to pry it open a tad to get the cable started into the slot and then pulled it all the way in. Then I slid the metal casing into the hole from the back and positioned it where I needed it to get full 100% throttle and locked it down.

Here's the side shot. You can see where I have the cable positioned in the rear holder and where it attaches to the carb arm. I took the bushing that comes with the bracket, drilled a hole in it, and put my throttle cable stud through the bushing. A nut on the back side secures it all. Note I bent the front part of the bracket down to give a bit more clearance to my upper rad hose. I also tweaked one of the 2 springs to reduce the load. And that was it...it took some layout work and head-scratchin' but I've been happy with it since I installed it - have not had to touch it at all.

View attachment 1715819396

Here's an overhead shot.

View attachment 1715819398

Hope this helps and doesn't add confusion!!

Yes, I figured it would have snapped. Cutting the slot bigger worked just fine and still locks in place with no issues. Sure does suck we have to modify stuff like this. They should have designed it with the back block a lot lower as most all of us hook the cable to the carb the way I showed in my pic. Right now I sure am glad I only paid $70ish for this bracket and not $100+ for the Holley model. It just may end up in the scrap pile...The difference between yours and @hunt2elk's bracket is, your cable is bare, while his still has the plastic casing. His bracket may have broken if he had tried to pry it open that far.

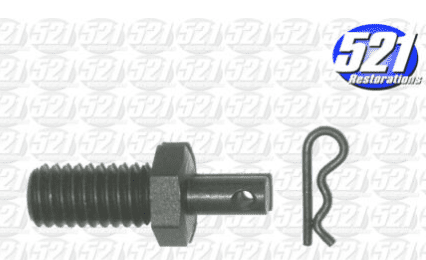

Yes, it helps, thanks for taking the time. Now I need to find a stud like you have. I have several of these, but of course they are not threaded long enough. Is yours aftermarket, or did it come stock on a certain model Mopar?Hope this helps and doesn't add confusion!!

You know, I honestly cannot recall what stud I used. I had several of them laying around and recall having to take some measurements and what-not. Was it a 4-speed stud similar to this eBay one?

I just cannot recall. I DO recall checking with some eBay vendors and having them measure some but I do not have any records showing what stud I ended up using.

I just cannot recall. I DO recall checking with some eBay vendors and having them measure some but I do not have any records showing what stud I ended up using.

The key as you note is to have the threaded part long enough to reach though the bushing. And also to get the 3/16" dia stud part where the throttle cable goes on - most of them are 1/4" and are too large (although a lathe could fix that - or even a hillbilly lathe like my drill press and file!). I know I also had the Edelbrock #8007 stud around here but no record if I used it. I'm sorry I couldn't get this across the finish line for you!

The key as you note is to have the threaded part long enough to reach though the bushing. And also to get the 3/16" dia stud part where the throttle cable goes on - most of them are 1/4" and are too large (although a lathe could fix that - or even a hillbilly lathe like my drill press and file!). I know I also had the Edelbrock #8007 stud around here but no record if I used it. I'm sorry I couldn't get this across the finish line for you!

Yes, that's one main reason I modified mine like I did. Using the cut factory clamp positions the cable right on top of the main bracket. Down low. The look doesn't match the snazzy new style bracket, but all I care about is function. Somebody doesn't like how it looks, well, it's not their car. lolYes, I figured it would have snapped. Cutting the slot bigger worked just fine and still locks in place with no issues. Sure does suck we have to modify stuff like this. They should have designed it with the back block a lot lower as most all of us hook the cable to the carb the way I showed in my pic. Right now I sure am glad I only paid $70ish for this bracket and not $100+ for the Holley model. It just may end up in the scrap pile...

Can you post a pic of what you did to yours RRR?Yes, that's one main reason I modified mine like I did. Using the cut factory clamp positions the cable right on top of the main bracket. Down low. The look doesn't match the snazzy new style bracket, but all I care about is function. Somebody doesn't like how it looks, well, it's not their car. lol

Now I'm curious...don't all throttle cables have the 2 metal collars? I have (and had) probably 5-6 Mopar cables and they all had that.

Interesting...I've never seen that before. Looks like an anti-wear feature as the cable slides in and out of the metal collar. That would sure do it - force a wider slot or removing the sleeve.

Thought I should update this thread. After messing around with this bracket for a couple of weeks, I finally gave up on it. It has a major design flaw imo and pointed out by RRR. The carb throttle linkage moves in an arc. This bracket has the cable mount positioned higher than the normal stud location on the carb. So it is impossible to get fully WOT. The only way to do it is having a custom stud made that will attach the cable to the same point as the throttle return spring setup like Demonx2 shows in his pics. I looked high and low trying to find a stud that would work to no avail.

Ended up writing a descriptive message to Summit, where I bought it. They agreed that either the cable hold down needs to be positioned lower, or they need to manufacture and include a stud that will allow the cable end and return springs to attach in the same location. So even though I had ground out the cable slot, Summit refunded my total purchase price and is sending it back to Allstar with a full description of the problem. Huge kudos to Summit for doing this even though I have doubts Allstar will make any changes.

Ended up writing a descriptive message to Summit, where I bought it. They agreed that either the cable hold down needs to be positioned lower, or they need to manufacture and include a stud that will allow the cable end and return springs to attach in the same location. So even though I had ground out the cable slot, Summit refunded my total purchase price and is sending it back to Allstar with a full description of the problem. Huge kudos to Summit for doing this even though I have doubts Allstar will make any changes.

skep419

5.9 Magnum 4 speed afficionado

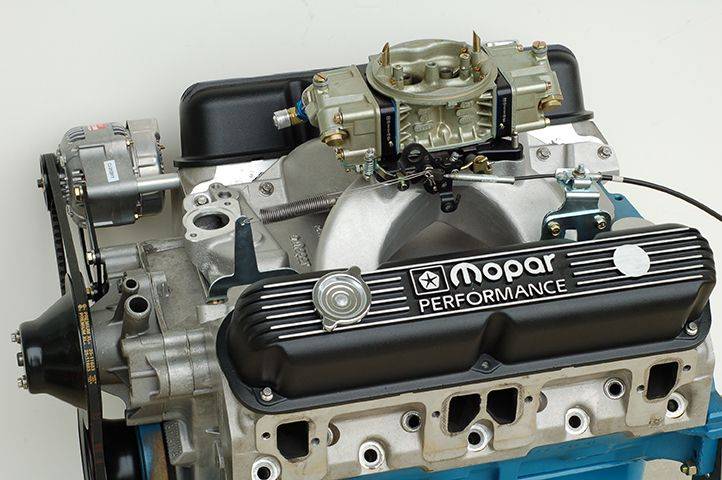

If I had to do it over I would have went with this. Is it the same one you didn’t like?

Mancini Racing Throttle Bracket Kit

Mancini Racing Throttle Bracket Kit

Yes that is what I originally had, and went back to. Come to find out I had a bad throttle cable causing my original issues.If I had to do it over I would have went with this. Is it the same one you didn’t like?

Mancini Racing Throttle Bracket Kit

View attachment 1715837980 View attachment 1715837981

-

Similar threads

- Replies

- 8

- Views

- 395

- Locked

- Replies

- 8

- Views

- 386