Might work as-shown since V-belts generally allow up to 1/8" axial offset with no problems, but would always bother you. You only need 1 belt on the alternator and water pump, unless using the factory RV2 AC compressor which needs 2 drive belts and the alternator to tension them. Many people use a modern Sanden AC compressor where a single belt suffices. As said, the alternator isn't the problem since same dimensions both early (roundback) and later (squareback), for all engines. A few had a single-groove pulley but most rebuilds have a dual pulley, which is good since allows more axial positioning choices.

Don't be tempted to change to a later aluminum water pump. I did that in my 1965 small-block and caused many problems. A bad choice due to what I could buy at Autozone soon after buying the car. The alum w.p. is 1" thicker, which allowed only a thin nylon fan to give radiator clearance. Also changes the side of the lower radiator hose.

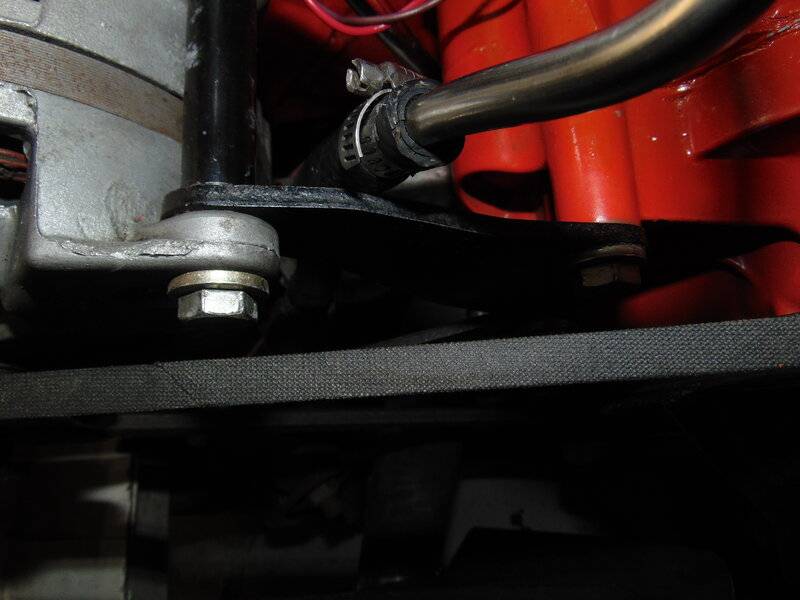

There were many different pulley setups over the years, between different engines and accessories, so quite confusing. As example, I rebuilt the TRW power steering pump on my 1965 small-block, but couldn't use it since no brackets for it with the aluminum water pump, so had to change to a later Federal pump w/ new brackets (Bouchillon Performance sells many brackets). I thought no problem since I'll use that p.s. pump on my 1965 big-block but found the pulley isn't correct and can't swap over the pulley from the big-block TRW pump since it has a thicker shaft. I finally rigged a belt setup which works, though was never a factory design. That is with a Sanden compressor on custom brackets I fabb'ed. In a do-over, I would use the OE cast-iron water pump.