snailpower

Well-Known Member

I recently yanked the original 318 out of my 72 scamp and replaced it with a 360 magnum. I didn't touch any of the (original) wiring and planned to reuse the 60a square back alternator, battery is new within the last 6 mos Optima red top. If it matters I am running an HEI on the stock distributor and not using the ballast or stock coil (has an e coil).

My buddy was the one who pulled the alternator when we did the 360 swap and instead of just undoing the connectors he pulled the brushes out of the alternator for some reason (didn't see the connectors I guess).

So when I hooked the alternator back up i was going by photos putting the brushes back in. to my (non) surprise it wasn't charging when I ran it. I ran it total maybe 30 mins like this and was seeing only around 12.2v at the battery when running, but no melting wires or anything.

My guess and try at a fix today was that the old motor didn't have a ground on the back of the engine to firewall just on the front so I added a ground from the passenger head to the firewall, and one from battery to core support. Along with the one to the front drivers head to the battery.

So today after I did that and inspected / cleaned the brush connections, i started it up and saw a puff of smoke from the engine. I shut it down immediately and the blue wire had already melted through its case and through the tape covering it in probably 30 seconds of run time.

My guess is that looking at the old 318 engine photo there are some "isolators" (maybe plastic washers?) there that got lost some how, and the screws grounded the 2 fields out on the case? would that be correct? Its weird that it didn't do this at first but did it later after I messed with the brushes and added grounds. The brushes didn't seem to fit too well and i did not see these small isolators in the bag for alternator parts we set aside.

So what am I looking at? At least replacing the blue wire which i am guessing goes to the voltage reg, would I need a new voltage reg too? I am picking up a new alternator tomorrow. Should I check for fried wires anywhere else?

Heres the photo version of the story:

Old 318, happily charging, here is the back of the alternator. no problems here.

New ground #1, battery to core support (cleaned metal below). the frayed wire in the foreground is a different wire:

New ground #2 on firewall to back of passenger head:

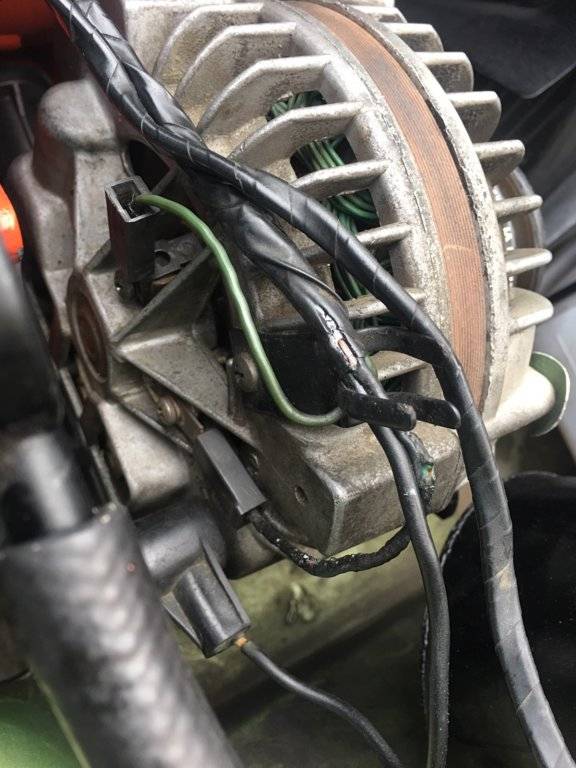

Melted wires, notice how the screws are not isolated from the case, the brushes sat kind of loose on there.

Melted wire:

Melted wire:

My buddy was the one who pulled the alternator when we did the 360 swap and instead of just undoing the connectors he pulled the brushes out of the alternator for some reason (didn't see the connectors I guess).

So when I hooked the alternator back up i was going by photos putting the brushes back in. to my (non) surprise it wasn't charging when I ran it. I ran it total maybe 30 mins like this and was seeing only around 12.2v at the battery when running, but no melting wires or anything.

My guess and try at a fix today was that the old motor didn't have a ground on the back of the engine to firewall just on the front so I added a ground from the passenger head to the firewall, and one from battery to core support. Along with the one to the front drivers head to the battery.

So today after I did that and inspected / cleaned the brush connections, i started it up and saw a puff of smoke from the engine. I shut it down immediately and the blue wire had already melted through its case and through the tape covering it in probably 30 seconds of run time.

My guess is that looking at the old 318 engine photo there are some "isolators" (maybe plastic washers?) there that got lost some how, and the screws grounded the 2 fields out on the case? would that be correct? Its weird that it didn't do this at first but did it later after I messed with the brushes and added grounds. The brushes didn't seem to fit too well and i did not see these small isolators in the bag for alternator parts we set aside.

So what am I looking at? At least replacing the blue wire which i am guessing goes to the voltage reg, would I need a new voltage reg too? I am picking up a new alternator tomorrow. Should I check for fried wires anywhere else?

Heres the photo version of the story:

Old 318, happily charging, here is the back of the alternator. no problems here.

New ground #1, battery to core support (cleaned metal below). the frayed wire in the foreground is a different wire:

New ground #2 on firewall to back of passenger head:

Melted wires, notice how the screws are not isolated from the case, the brushes sat kind of loose on there.

Melted wire:

Melted wire:

Worth a shot to maybe find some isolators and give it a shot?

Worth a shot to maybe find some isolators and give it a shot?