You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ammeter to Voltmeter...who does it?

- Thread starter billytuffnuts

- Start date

-

My bulkhead connector is gone. Installing a painless wiring harness. 10gauge wire from alternator to the ignition switch side of a 70 amp maxi-fuse. I see the NTE 960 out there, what size cap did you use? Soldered across pin 1 and 2? pin 3 is 5V out? Also, anyone know where I can buy replacement crimp connectors that go onto the pins on the instrument panel?

moparmat2000

Well-Known Member

Actually modfing the gage its a bit more than clipping the wire. I revised that to removing the regulator vibrating tab too. You leave the studs intact on the back of the gage so you have a spot for the ring terminals to attach for the IVR in the rallye dash

moparmat2000

Well-Known Member

My bulkhead connector is gone. Installing a painless wiring harness. 10gauge wire from alternator to the ignition switch side of a 70 amp maxi-fuse. I see the NTE 960 out there, what size cap did you use? Soldered across pin 1 and 2? pin 3 is 5V out? Also, anyone know where I can buy replacement crimp connectors that go onto the pins on the instrument panel?

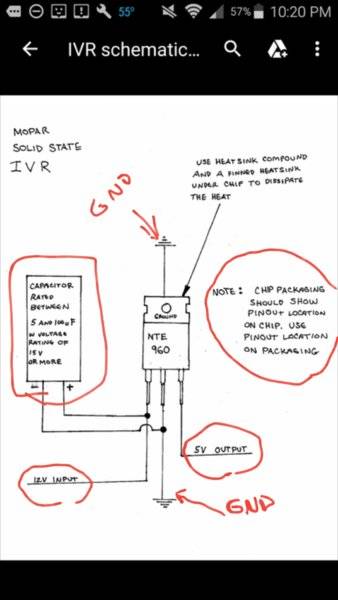

Heres the schematic. Solder the capacitor to the 960 as shown on the NTE 960 package. The schematic is representative, always wire up to the pin outs shown on the packaging for the chip. Negative leg of the capacitor goes to the negative ground leg of the chip. It will have to be soldered in that way. Schematic says capacitor to use needs to have a value between 5 and 100 microfarads, and be rated for 15v. Or more. This is a very simple circuit i have drawn up. Follow the wire tracings on the pic

Last edited:

moparmat2000

Well-Known Member

Easy peasy

I need to thank all of you for this thread. While I don't own an A Body (or any other letter Body for that matter), I do own a 1975 MB300 Class C motorhome. I've been restoring it for the past two years, and we're at the point where we can take day trips in it now. We took it out today and the ammeter pretty much stayed at +25 during our entire trip, the first time it's done that. One of the things I did was to rebuild the wiring harness, including taking the wires out of the firewall blocks and cleaning them with BarKeeper's Friend, then packing the blocks with dielectric grease and replacing the wires.

I've decided to get rid of the ammeter and replace it with a voltmeter, however my ammeter is different from your A-Body cars...it's located in a four-gauge round cluster and the needle points down. I did manage to find two different brands of voltmeters, so I'll be doing this upgrade this winter. I do have one question, though. The ammeter has a 20A circuit breaker attached to one of the posts (see picture below)...do I need to keep it, when I convert it over to the voltmeter?

Thanks again.

Fred

I've decided to get rid of the ammeter and replace it with a voltmeter, however my ammeter is different from your A-Body cars...it's located in a four-gauge round cluster and the needle points down. I did manage to find two different brands of voltmeters, so I'll be doing this upgrade this winter. I do have one question, though. The ammeter has a 20A circuit breaker attached to one of the posts (see picture below)...do I need to keep it, when I convert it over to the voltmeter?

Thanks again.

Fred

moparmat2000

Well-Known Member

If i had to guess, the circuit breaker is there because an ammeter measures the current flow. Too much current flow and it breaks the circuit before any damage can occur. All your alternators output power flows through the ammeter before going to the battery. By contrast a volt meter is only going to take a sample reading of the voltage level and not current or amps. Not sure if this makes sense to you. I would assume by changing over to a volt gage you no longer need the circuit breaker at the gage.

Your van cluster ammeter setup is similar to the 67-71 rallye dash cluster in which it has 4 instruments in one location. Only difference being the A body rallye cluster it faces up. Not a big deal if your volt gage has a potentiometer on it, you can fine tune the needle adjustment where you want it to sit at a given voltage.

How i adjusted the one for my barracuda was i took a car battery and set it on my workbench and measured its voltage. Then i hooked up the volt gage to the battery with alligator clip test leads, and oriented it in my hand how its positioned in the gage panel, and adjusted the needle position with the potentiometer. For me 13 5V is slightly above middle line towards charge on my ammeter.

The circuit breaker you would need to reuse however. I would put it somewhere between your battery positive post and the alternator output wire going to the battery. Maybe a convienent location on the firewall.

When you hook up your volt gage in the instrument cluster, i recommend grounding your negative gage post right to the metal cluster housing, and enlarge the positive post hole for a plastic grommet and plastic washers to insulate it. Find the 12V feed that goes into the cluster from the body wiring plug. And trace that to the IVR input side, and run a wire tap off of there to your 12V input to your volt gage.

I noticed your gage face does read opposite of the A body cars. It may be a simple solution. Theres companies out there that make repair decals for vehicle gages. They may have these for dodge vans, and may be able to make you up a decal thats volts instead of amps, you may be able to explain to them that the scale on the decal needs to be opposite of whats there.

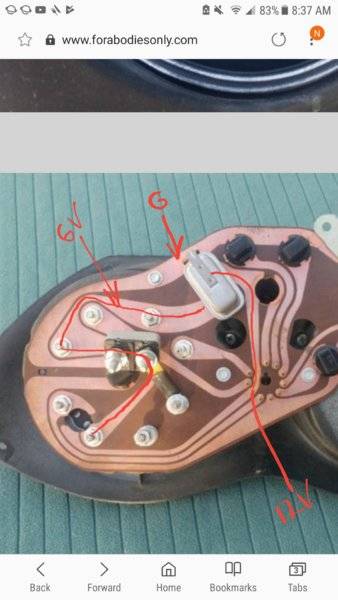

IVR (instrument voltage regulator) is the rectangular tin box with prongs on it plugged into the cluster.circuit board. It regulates 12v down to 5v for fuel level, water temp, and oil pressure gages. Its a set of vibrating points. They worked great when new but get weird when they get old. If it sticks open the gages drop, if it sticks closed the peg out.

There are 2 solutions to this problem. You can buy a plug n play solid state one for about $30. Plug it in and its done, or your can wire up your own with an NTE960 semiconductor and a 100 microfarad capacitor for about $3. I went the $3 route because chrysler stuck the IVR inside the fuel gage on the rallye dash, and i had to dissassemble and gut the IVR side of the instrument while leaving the fuel level side of the gage intact. Since your is plug n play on the back of the circuit board i would recommend just buying a solid state replacement, plug it in and done.

I hope this helps you out a bit. Its hard to see what would fit the cluster you have without taking it apart and seeing what it looks like on the inside.

Your van cluster ammeter setup is similar to the 67-71 rallye dash cluster in which it has 4 instruments in one location. Only difference being the A body rallye cluster it faces up. Not a big deal if your volt gage has a potentiometer on it, you can fine tune the needle adjustment where you want it to sit at a given voltage.

How i adjusted the one for my barracuda was i took a car battery and set it on my workbench and measured its voltage. Then i hooked up the volt gage to the battery with alligator clip test leads, and oriented it in my hand how its positioned in the gage panel, and adjusted the needle position with the potentiometer. For me 13 5V is slightly above middle line towards charge on my ammeter.

The circuit breaker you would need to reuse however. I would put it somewhere between your battery positive post and the alternator output wire going to the battery. Maybe a convienent location on the firewall.

When you hook up your volt gage in the instrument cluster, i recommend grounding your negative gage post right to the metal cluster housing, and enlarge the positive post hole for a plastic grommet and plastic washers to insulate it. Find the 12V feed that goes into the cluster from the body wiring plug. And trace that to the IVR input side, and run a wire tap off of there to your 12V input to your volt gage.

I noticed your gage face does read opposite of the A body cars. It may be a simple solution. Theres companies out there that make repair decals for vehicle gages. They may have these for dodge vans, and may be able to make you up a decal thats volts instead of amps, you may be able to explain to them that the scale on the decal needs to be opposite of whats there.

IVR (instrument voltage regulator) is the rectangular tin box with prongs on it plugged into the cluster.circuit board. It regulates 12v down to 5v for fuel level, water temp, and oil pressure gages. Its a set of vibrating points. They worked great when new but get weird when they get old. If it sticks open the gages drop, if it sticks closed the peg out.

There are 2 solutions to this problem. You can buy a plug n play solid state one for about $30. Plug it in and its done, or your can wire up your own with an NTE960 semiconductor and a 100 microfarad capacitor for about $3. I went the $3 route because chrysler stuck the IVR inside the fuel gage on the rallye dash, and i had to dissassemble and gut the IVR side of the instrument while leaving the fuel level side of the gage intact. Since your is plug n play on the back of the circuit board i would recommend just buying a solid state replacement, plug it in and done.

I hope this helps you out a bit. Its hard to see what would fit the cluster you have without taking it apart and seeing what it looks like on the inside.

Last edited:

moparmat2000

Well-Known Member

Looks like this is your IVR routing

You're correct, that is the IVR routing, but mine steps it down to 5V, per my service manual. Here's a different angle of the circuit board, before I cleaned up the copper with BarKeeper's Friend.

on edit: I just took a look at my service manual again....that circuit breaker on the back of the ammeter is for the trailer towing package. I guess I do need to save it and just tie it inline with the battery positive post and the alternator output wire going to the battery, as you said. I don't know how people get along without the original Mopar Service Manuals.

Last edited:

Mattax

Just the facts, ma'am

Sorry, this is a Misconception! On a Mopar, Jeep and most other cars with an ammeter, all of the alternator's power flows to the main junction and from there is divided up. Some goes to ignition, additional may go to lights, radio, etc. Only the portion needed for recharging the battery goes through the ammeter.All your alternators output power flows through the ammeter before going to the battery.

Something is wrong. First check to see if the motorhome's ammeter is in fact on the charging circuit. Other non-automotive equipment do use ammeters to measure power output (as moparMatt2000 thought). If so, they will be very robust setups.and the ammeter pretty much stayed at +25 during our entire trip, the first time it's done that.

If it is on the charging circuit, then the possibilites are:

something additional has been wired to it by connecting at or near the battery.

the battery is very low

the ammeter mechanism isn't working right.

While most cars with ammeters have an internal shunt (big metal plate that carries the current), mid to later 70s some cars got externally shunted ammeters. The external shunt is heavy wire, could be in the engine compartment, that the ammeter mechanism was precisely calibrated to match.,

moparmat2000

Well-Known Member

The NTE960 can take up to 35V input and put out 5.5V output, which should be fine for an IVR. I said 6V sorry i meant to type 5V. I should proofread better.

moparmat2000

Well-Known Member

The circuit breaker looks to be tapped off the side of the ammeter wiring thats coming from the alternator. This may have been an add in by the motor home manufacturer. Not sure. But if it is, and you convert to a volt gage, i would tap it back in where you would connect the 2 ammeter leads together sandwiching it in with those 2 leads and leave it right where it is.

The circuit breaker looks to be tapped off the side of the ammeter wiring thats coming from the alternator. This may have been an add in by the motor home manufacturer. Not sure. But if it is, and you convert to a volt gage, i would tap it back in where you would connect the 2 ammeter leads together sandwiching it in with those 2 leads and leave it right where it is.

It was actually a Mopar part, added to the chassis cab at the Warren Truck Plant. Some chassis cabs got it, some didn't. I don't remember the option code off the top of my head, but it was definitely a Mopar option. Since I plan on doing the MAD bypass, would it matter where in the wiring I put that 20A circuit breaker? Firewall in the engine compartment does seem like a better place.

Something is wrong. First check to see if the motorhome's ammeter is in fact on the charging circuit. Other non-automotive equipment do use ammeters to measure power output (as moparMatt2000 thought). If so, they will be very robust setups.

If it is on the charging circuit, then the possibilites are:

something additional has been wired to it by connecting at or near the battery.

the battery is very low

the ammeter mechanism isn't working right.

You just jogged my memory.

My junction blocks. The ammeter is definitely on the charging circuit. The fusible link is NOS...my old one was crunchy but not yet burned out.

The 10ga. positive wire with the inline fuse goes to the coach/house battery charging solenoid. Maybe this is causing the ammeter to read +25, because the coach/house battery is on its last legs. The chassis van battery is brand new.

The coach/house battery charging solenoid. The middle post is the 12v switched power to energize the solenoid; 10ga. red wire on the right is the one from the chassis van battery; grey wire on the left is to the coach/house battery. Yellow wire is what I used to go to my electric fuel pump, which is by the fuel tank...there are no switched 12V sources back there.

My plan, once I do the ammeter bypass, is to run a 10ga. wire from the alternator directly to the coach/house battery charging solenoid, instead of having it run from the chassis cab battery, that way the chassis cab battery isn't having to be the conduit to charge the coach/house battery.

Thanks for indulging my questions/pics. The Vanning Forum is practically defunct. There hasn't been a viable tech post in years and membership is mostly European.

Last edited:

Mattax

Just the facts, ma'am

Please hold off until you have this all mapped out. It's not as brilliant an idea as they claim, and most important, the method they suggest puts unneccessary resistance in the power feed.Since I plan on doing the MAD bypass

Very interesting.My junction blocks. The ammeter is definitely on the charging circuit. The fusible link is NOS...my old one was crunchy but not yet burned out.

Junction block. When I wrote "main junction" I was referring to a distribution center. What I see in the photo are the bulkhead connectors. On the side power is distributed at one or more big welded splices and a the fuse panel.

The fusible link is pretty much a wire with special insulation. Its probably the insulation that is getting crunchy. It takes a lot of current to melt a fusible link. It's mostly to stop a battery discharging through a short to ground.

With the ammeter in the charging circuit, its probably internally shunted. I don't see a connection from the battery to alternator in the engine bay - that's typically what we'ld see with an externally shunted ammeter.

Very interesting.The 10ga. positive wire with the inline fuse goes to the coach/house battery charging solenoid. Maybe this is causing the ammeter to read +25, because the coach/house battery is on its last legs. ...The coach/house battery charging solenoid.

It could be. I assume this solenoid is always on when the key is in 'run' or is it manually switched?

Normally, a low battery will draw a lot of current at first, but then as it charges less and less. High recharge current means lots of chemical activity in the battery and that produces heat. That internal heat makes it more difficult to recharge. The small wire on the fuse may restrict the recharging current somewhat, which is good but best would be to recharge that battery on a slow charger.

Anyway, its pretty easy to test the possibility by taking it off the circuit. Just watch where loose hot wires are!

Mattax

Just the facts, ma'am

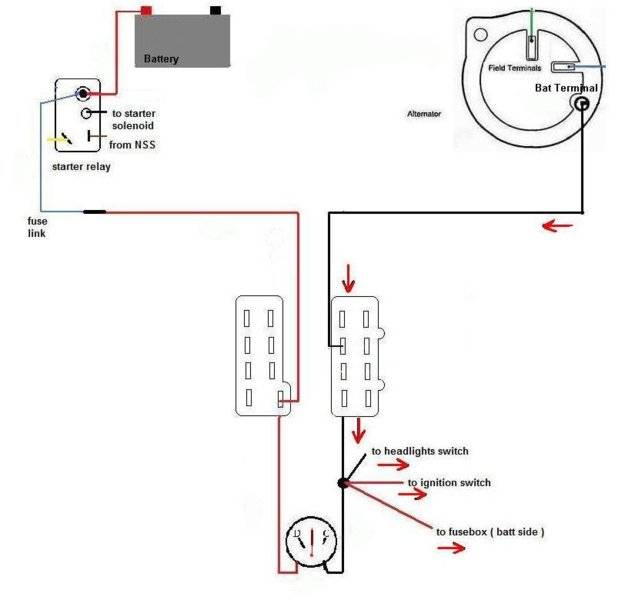

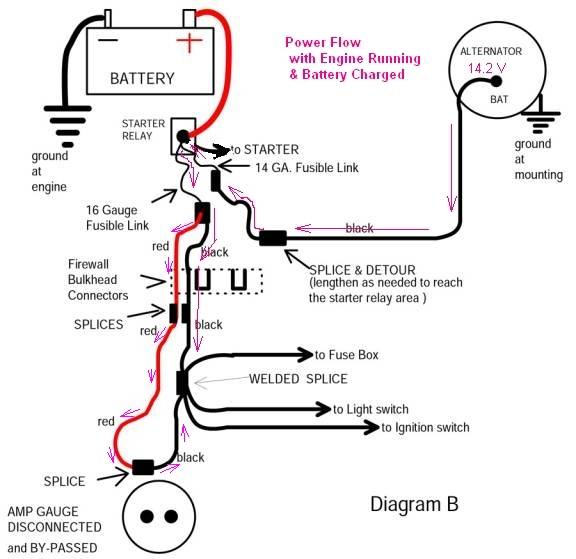

Diagram of current flow on a normal car with fully charged battery.

The power is first distributed at a splice.

No current normally goes through the ammeter.

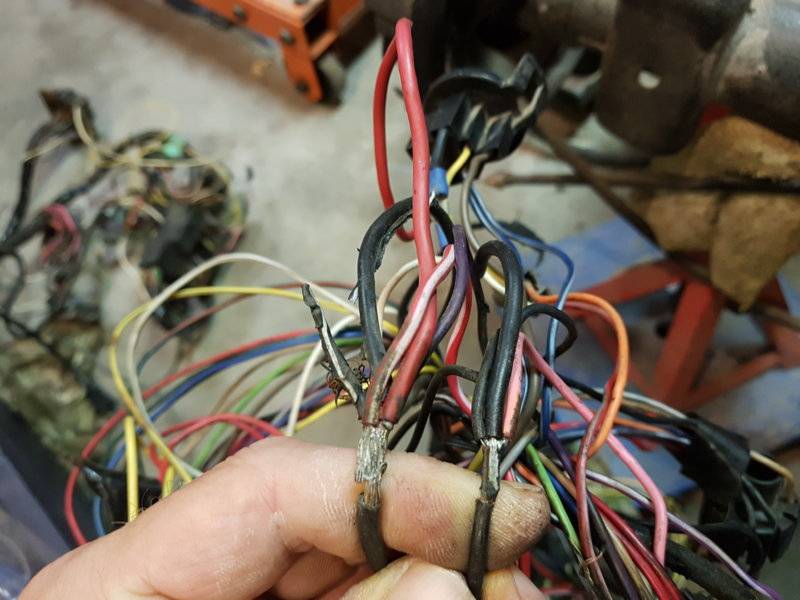

Here's a picture of some welded splices unwrapped posted by another member.

The power is first distributed at a splice.

No current normally goes through the ammeter.

Here's a picture of some welded splices unwrapped posted by another member.

Please hold off until you have this all mapped out. It's not as brilliant an idea as they claim, and most important, the method they suggest puts unneccessary resistance in the power feed.

What is the preferred method for getting rid of the ammeter and replacing with a voltmeter? Is there a way to limit the resistance in the power feed?

Very interesting.

Junction block. When I wrote "main junction" I was referring to a distribution center. What I see in the photo are the bulkhead connectors. On the side power is distributed at one or more big welded splices and a the fuse panel.

The fusible link is pretty much a wire with special insulation. Its probably the insulation that is getting crunchy. It takes a lot of current to melt a fusible link. It's mostly to stop a battery discharging through a short to ground.

With the ammeter in the charging circuit, its probably internally shunted. I don't see a connection from the battery to alternator in the engine bay - that's typically what we'ld see with an externally shunted ammeter.

Yeah, sorry, they are bulkhead connectors. I'm still on my first cup of coffee. The old fusible link insulation was still pliable...the wires inside were crunchy. I sliced the insulation just to see what it looked like inside. Honestly, I don't know if the ammeter is internally shunted, so I'll take your word for it that it is. No, there is no connection from the alternator to the battery. If you look at the far left bulkhead connector the 10ga. black wire in the lower right is from the alternator and, in turn, goes to the ammeter.

Very interesting.

It could be. I assume this solenoid is always on when the key is in 'run' or is it manually switched?

Normally, a low battery will draw a lot of current at first, but then as it charges less and less. High recharge current means lots of chemical activity in the battery and that produces heat. That internal heat makes it more difficult to recharge. The small wire on the fuse may restrict the recharging current somewhat, which is good but best would be to recharge that battery on a slow charger.

Anyway, its pretty easy to test the possibility by taking it off the circuit. Just watch where loose hot wires are!

It's on, when the key is switched. I used the 12V switched wire that used to go to my EGR module, which I deleted. It is constant 12V, and I didn't want to tap into a wire at the bulkhead connector, as the PO did. It's definitely a learning experience and reminds me of my first car, when I was a young 18 year-old Private, a 1965 318 Satellite. That car was what made me learn how to turn wrenches.

This is a pic of the bulkhead connectors, before I took everything apart, cleaned, repaired and reassembled.

Mattax

Just the facts, ma'am

The problem with MAD's design is all the power to run the vehicle must go through several more splices and two fusible links.

Even in a situation where recharging a very low battery is frequently needed, this is not a good design.

If say, with a situation like your motor home, high current charging is frequently needed. Then a charging wire with fusible link can be added, but leave the alternator feed to the main junction as is.

Even in a situation where recharging a very low battery is frequently needed, this is not a good design.

If say, with a situation like your motor home, high current charging is frequently needed. Then a charging wire with fusible link can be added, but leave the alternator feed to the main junction as is.

Mattax

Just the facts, ma'am

There's almost certainly a big spliced junction before the ammeter.If you look at the far left bulkhead connector the 10ga. black wire in the lower right is from the alternator and, in turn, goes to the ammeter.

If it the ammeter reads zero when the engine is running and the battery is charged, that's what's going on.

The alternator is supplying power at 14 Volts give or take some. Power flows from the highest voltage source to the where ever its asked for. The battery is only 12.5 Volts give or take, so the alternator is sending the current to the ignition etc, but we don't see it on the ammeter 'cause its not in the alternator's output line.

moparmat2000

Well-Known Member

I agree with your schematic to a point. However once you run the alternators output directly to the battery bypassing the bulkhead connector entirely, as long as the spades are clean and tight, you shouldent have to bypass the feed going back through them to the rest of the car because the load on the connectors shouldent be that high anymore, and the amp load is now split between 2 feeds going in through the bulkhead. I modified the schematic showing 2 voltage feeds through the bulkhead this splits the load going in.The problem with MAD's design is all the power to run the vehicle must go through several more splices and two fusible links.

Even in a situation where recharging a very low battery is frequently needed, this is not a good design.

If say, with a situation like your motor home, high current charging is frequently needed. Then a charging wire with fusible link can be added, but leave the alternator feed to the main junction as is.

View attachment 1715235459

Now on a motorhome, and its systems loading the wiring, he may want to use your schematic and bypass the bulkhead altogether. However in a passenger car, its not necessary.

See my modification of the schematic below.

The problem with MAD's design is all the power to run the vehicle must go through several more splices and two fusible links.

Even in a situation where recharging a very low battery is frequently needed, this is not a good design.

If say, with a situation like your motor home, high current charging is frequently needed. Then a charging wire with fusible link can be added, but leave the alternator feed to the main junction as is.

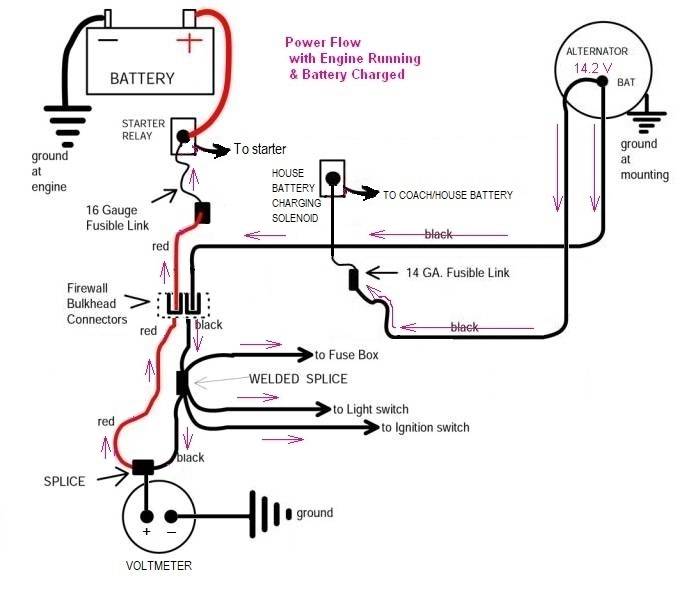

So I would want a setup like this then? I redrew the MAD drawing you posted, to reflect the alternator wire running through the bulkhead connector.

Mattax

Just the facts, ma'am

Matt, You can still avoid out the extra splices and fusible link by leaving the alternator feed alone. For most people skills, that may be best. Agreed, a parallel wire through grommet would provide even higher capacity. Also agreed the motorhome with second battery that needs recharging is different case than the typical car.

One device thats available today which may help is the solar powered battery chargers. Connecting one to the coach battery would help keep it charged.

Ammeter internal shunt

1973 Imperial and Chrysler Electrical Circuit Troubleshooting Reference Service Repair Book from the Master Technician's Service Conference Session 311

One device thats available today which may help is the solar powered battery chargers. Connecting one to the coach battery would help keep it charged.

Ammeter internal shunt

1973 Imperial and Chrysler Electrical Circuit Troubleshooting Reference Service Repair Book from the Master Technician's Service Conference Session 311

Matt, You can still avoid out the extra splices and fusible link by leaving the alternator feed alone. For most people skills, that may be best. Agreed, a parallel wire through grommet would provide even higher capacity. Also agreed the motorhome with second battery that needs recharging is different case than the typical car.

One device thats available today which may help is the solar powered battery chargers. Connecting one to the coach battery would help keep it charged.

Ammeter internal shunt

1973 Imperial and Chrysler Electrical Circuit Troubleshooting Reference Service Repair Book from the Master Technician's Service Conference Session 311

So this sounds like the following drawing would be the way I need to go, since I would need a fusible link to protect the feed to the coach/house battery charging solenoid.

Mattax

Just the facts, ma'am

Not quite. Now its back stock. Which IMO may be fine - everything you show looks pretty heavy duty and clean (except the crunchy fusible liunk)So I would want a setup like this then? I redrew the MAD drawing you posted, to reflect the alternator wire running through the bulkhead connector.

View attachment 1715235466

View attachment 1715235467Click For Full-Size Image.

(Edit: yes like in the post above. You got it! No need to lengthen or cut anything, just add one wire with link. You can keep or the ammeter or not, it just won't read the battery charging. It probably will read the battery discharging at start. That's what mopartim observed. Probably 'cause its the shortest route to the main splice from the battery.)

Something like this

Last edited:

Not quite. Now its back stock. Which IMO may be fine - everything you show looks pretty heavy duty and clean (except the crunchy fusible liunk)

(Edit: yes like in the post above. You got it! No need to lengthen or cut anything, just add one wire with link. You can keep or the ammeter or not, it just won't read the battery charging. It probably will read the battery discharging at start. That's what mopartim observed. Probably 'cause its the shortest route to the main splice from the battery.)...

So, final electrical schematic design, and it looks like we have a winner. My Dad was an electrical engineer at Westinghouse, and he taught me enough to be dangerous, LOL!

Or I think I can skip connecting the 10ga. black wire with the fusible link to the starter relay and, instead, run it directly to the Coach/House battery charging solenoid, like the picture below. I think this will be a cleaner setup.

Last edited:

-

Similar threads

- Replies

- 5

- Views

- 189

- Replies

- 16

- Views

- 872

- Replies

- 3

- Views

- 401