You're being held back by an extension cord? Really?I would have gotten farther but my welding lead doesn't reach far enough. Tomorrow I'll have to use a jack to slide the car over and roll it partway into the garage.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another Mopar Off My Bucket List - Barracuda Fastback

- Thread starter 1967 'cuda

- Start date

-

Seriously,it happens 66..... I had a shopmate,who ran an 80 foot 110 extension cord combination,to wire wheel an Ford Maverick front suspension for clean up. They cables weren't even touchable... I told him to plug into his brother's 110 outlet,or I was going to raise his rent. Yes,it can happen....You're being held back by an extension cord? Really?

I'm not trying to start an argument here but if you get an extension cord with an adequate amperage rating, you should be fine. If the cross-section area of the copper is large enough, the losses can be kept at a safe level. Use the shortest cable possible, too. It's probably best to only have have AWG 12 extension cords in the shop. Or maybe even AWG 10. They are pretty beefy, though ...Seriously,it happens 66..... I had a shopmate,who ran an 80 foot 110 extension cord combination,to wire wheel an Ford Maverick front suspension for clean up. They cables weren't even touchable... I told him to plug into his brother's 110 outlet,or I was going to raise his rent. Yes,it can happen....

The duty cycle is important, too. If you're running an angle grinder, you're running it continuously. The welder prbably doesn't see more than 20-50% duty cycle.

Here's a good guide I found:

Buying Guide: Extension Cords at The Home Depot

Last edited:

Not disagreeing at all ,Anders.. That was my point to the guy,lol.. I didn't have shop insurance,& had some valuable cars.. Completely agree,with you...I'm not trying to start an argument here but if you get an extension cord with an adequate amperage rating, you should be fine. If the cross-section area of the copper is large enough, the losses can be kept at a safe level. Use the shortest cable possible, too. It's probably best to only have have AWG 10 extension cords in the shop. Or maybe AWG 12.

Here's a good guide I found:

Buying Guide: Extension Cords at The Home Depot

*phew* I'm glad!

I edited my post, though. I didn't realize how beefy the AWG10 and even 12 wires are. You guys really suffer from the lower voltage ...

I edited my post, though. I didn't realize how beefy the AWG10 and even 12 wires are. You guys really suffer from the lower voltage ...

Lol...^^^^^ I don't argue ,in mechanical situations,everyone has a different thought process to get there...

1967 'cuda

Dropped on Head as a Baby

You're being held back by an extension cord? Really?

Just one thing you need to remember. I'm a cheap bastard. LOL. I've got a 25' AWG 8 extension that gets the welder to the opposite end of the garage and my stinger will reach out the door another 15'. I could really use another 10' though.

Last edited:

Hi,John ..Agreed on electric in home issues.. I think my best 110 breakers were once garage ,now in a make shift 4th bed room... Neighbors ,look at me strangely....Just one thing you need to remember. I'm a cheap bastard. LOL. I've got a 25' AWG 8 extension that gets the welder to the opposite end of the garage and my stinger will reach out the door another 15'. I could really use another 10' though.

AWG 8. Wow. That's a lot of copper ...Just one thing you need to remember. I'm a cheap bastard. LOL. I've got a 25' AWG 8 extension that gets the welder to the opposite end of the garage and my stinger will reach out the door another 15'. I could really use another 10' though.

Agreed....AWG 8. Wow. That's a lot of copper ...

1967 'cuda

Dropped on Head as a Baby

Hi,John ..Agreed on electric in home issues.. I think my best 110 breakers were once garage ,now in a make shift 4th bed room... Neighbors ,look at me strangely....

My 110 chop saw still trips the breaker when I'm cutting through heavy steel. I should get a heavier cord for it. Too often I 'make do' with what I have when I should re-do instead.

Last edited:

1967 'cuda

Dropped on Head as a Baby

AWG 8. Wow. That's a lot of copper ...

It was the longest AWG 8 that Menards had on hand when I bought it. I thought it'd suit me fine because it'd reach from one end of the garage to the other. I guess I hadn't planned on welding outside.

Last edited:

You should lock it up. Copper thieves could feed their families for weeks off of it!

1967 'cuda

Dropped on Head as a Baby

You should lock it up. Copper thieves could feed their families for weeks off of it!

CRAP! I think my place is becoming a smorgasbord for thieves.

Last edited:

1967 'cuda

Dropped on Head as a Baby

I never get as much accomplished as what I plan. It's not that I don't try, but I move pretty slow and need to take a lot of breaks. I guess my planned objectives are on a time schedule I used to be able to keep pace with.

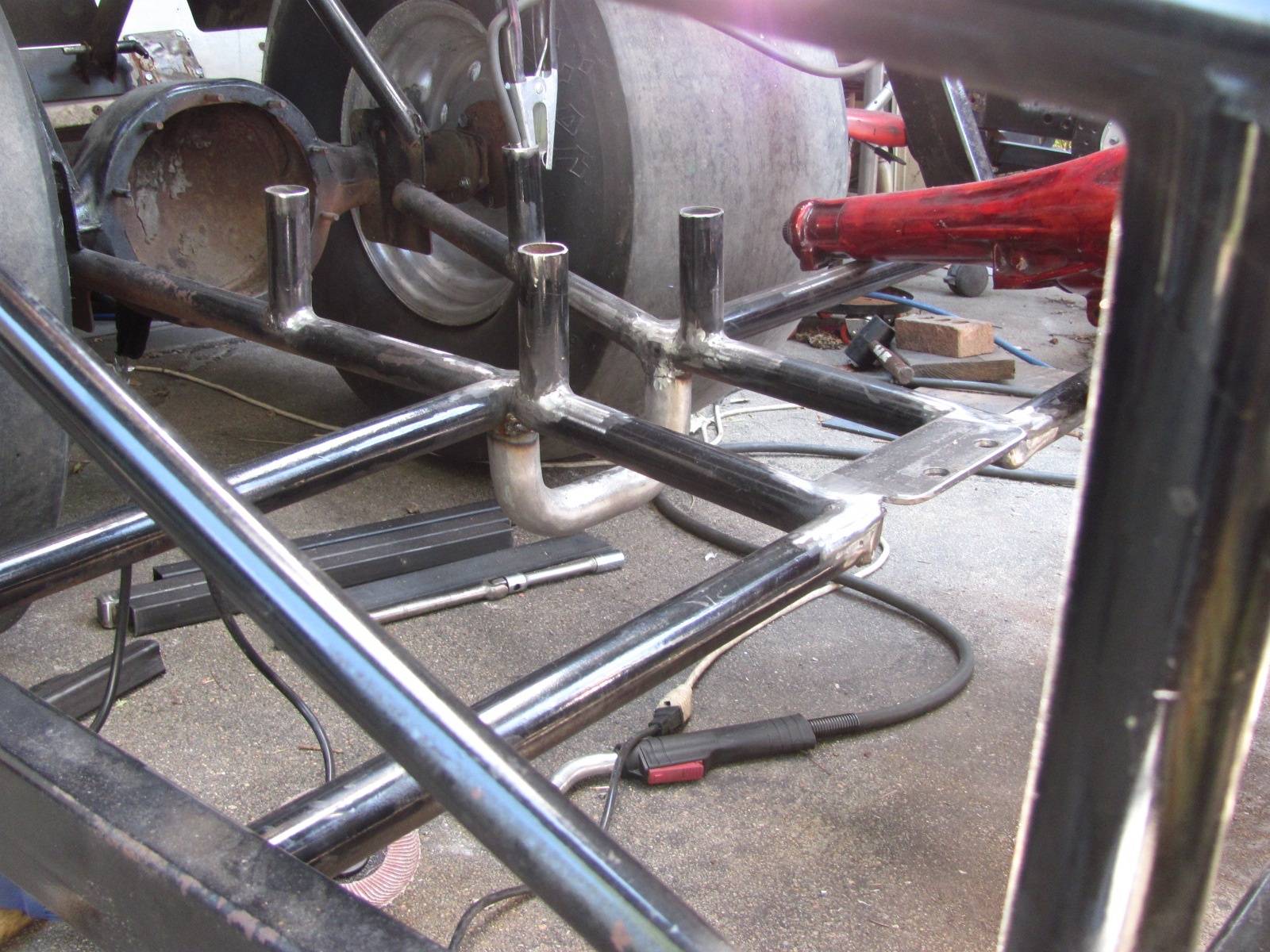

Nonetheless, I did make further progress today. I started out fabricating a rear transmission mount. I oversized the holes to allow for the transmission to slide forward if I eliminate the 1/4" extra space the rear engine plate uses. I'll use large washers when it's bolted together. I also cut out the last bar that interfered with the future driveshaft.

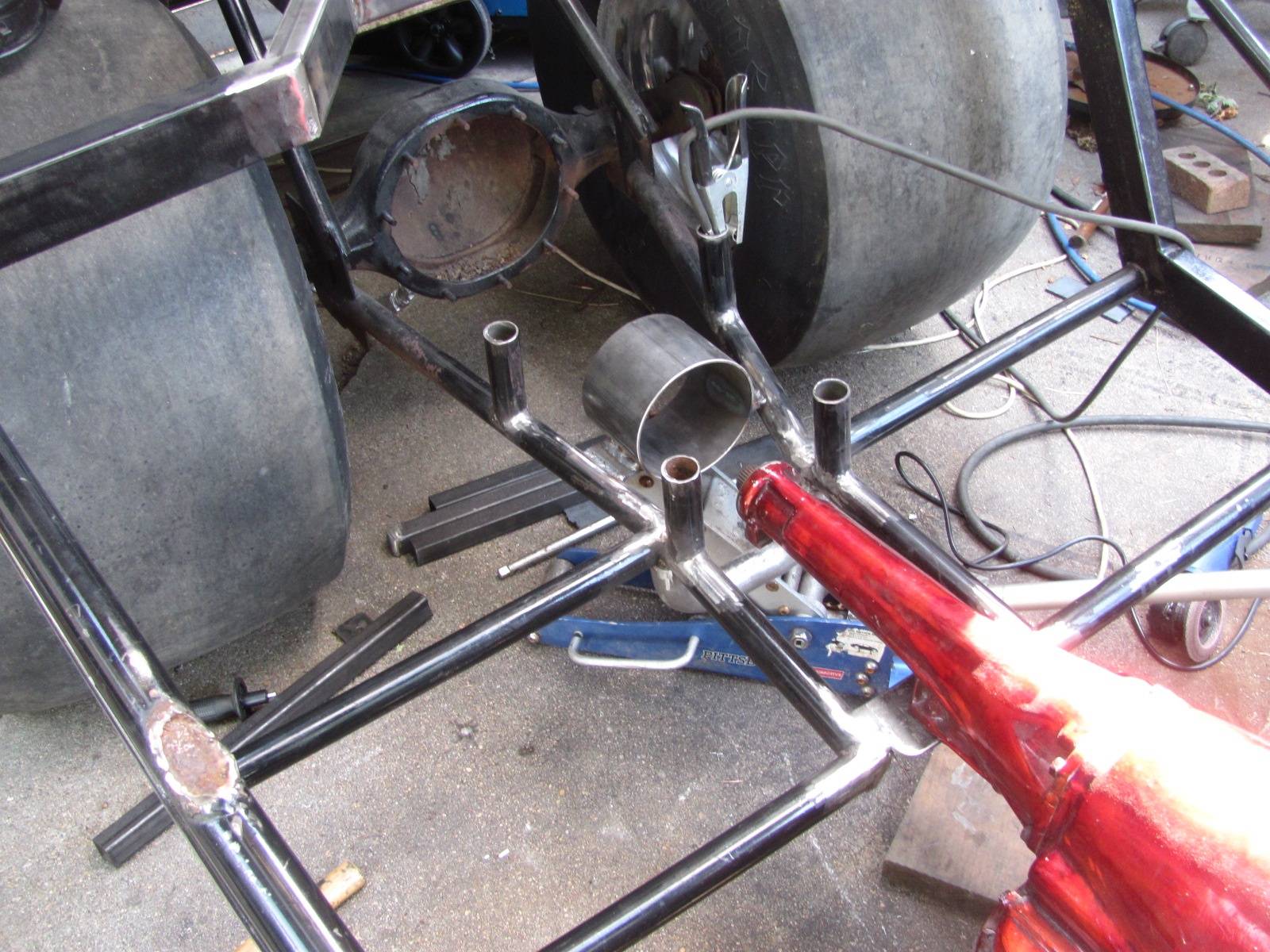

After finishing the transmission mount I welded in a dropped frame cross-member to take the place of the bar I'd cut out. I fabbed the new cross-member out of 4 45' steel elbows and 3 short sections of 1&1/2" tubing. All welded up it looks like a single bent piece.

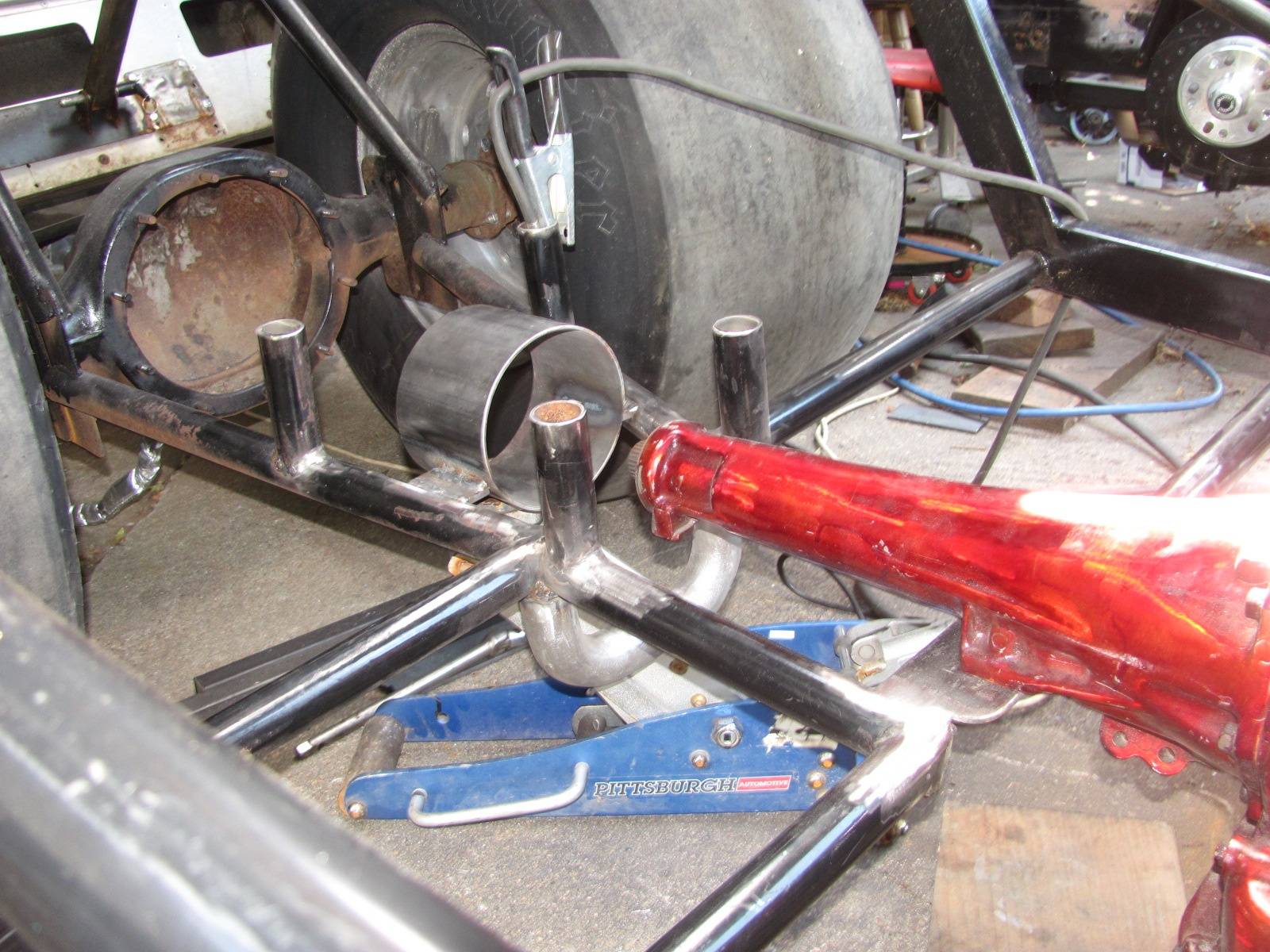

After that I went ahead and welded in the driveshaft loop that I made. Having to remove and re-install the transmission several times is starting to scratch up the pretty red paint. - Oh well.

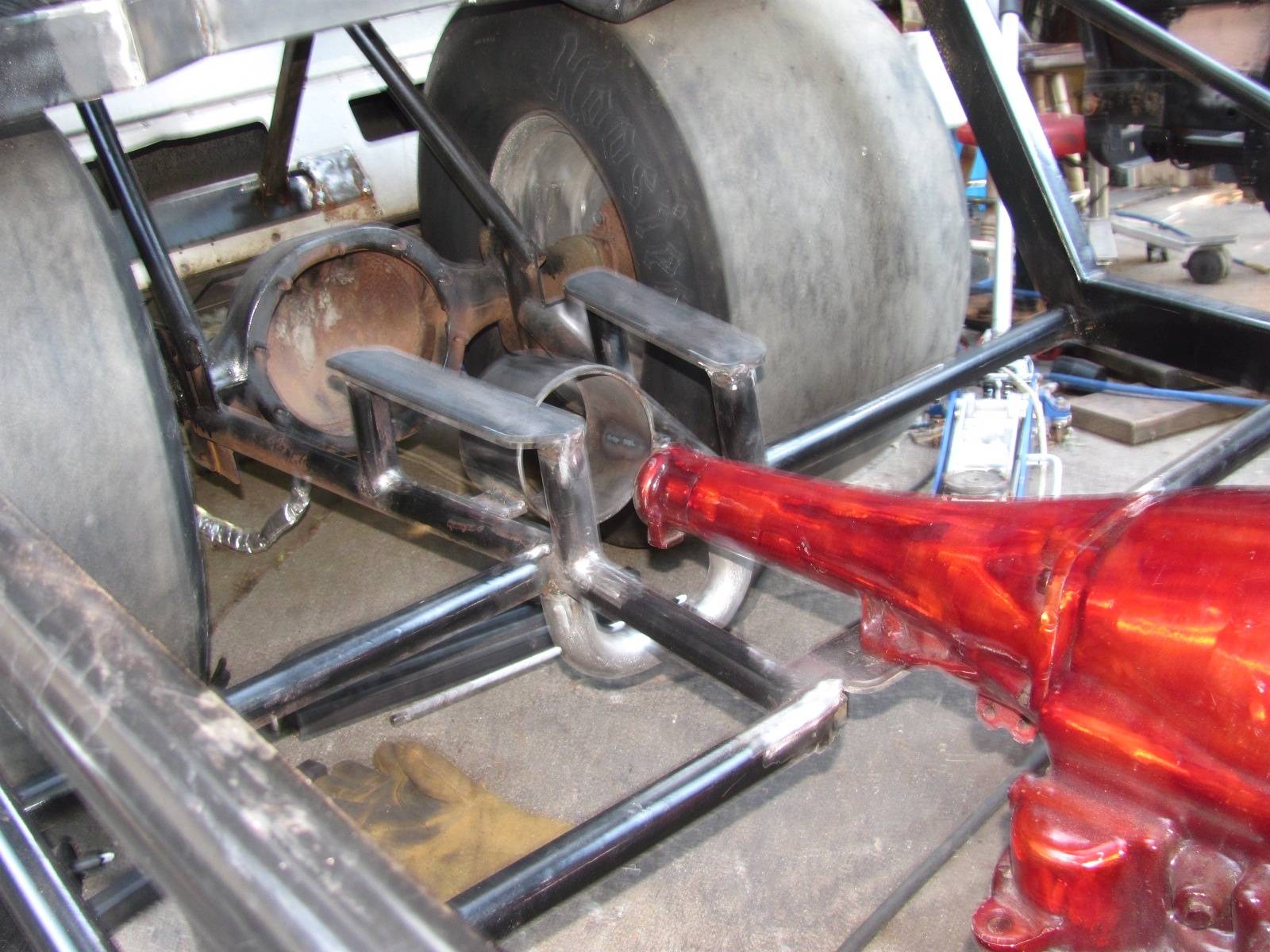

With the loop done I went ahead and welded the 2 straps that the seat bolts down to. They look a little odd but I made them that way on purpose. It's hard to explain, but there's a method to my madness.

The seat is the right height with the roof now. I still need to drill the holes in my brackets so I can bolt it back down.

My next move was to start working on that floor. Rather than cut out the old round cross-members and raise them, I decided to add 1&1/4" square tubing above that would match the height of the original rectangular cross-members & frame. - That way I wouldn't be drilling into (and weakening) the existing cross-members.

I didn't get done before the sun started setting. I only got half of it tacked together. I'll pull these pieces back off and weld any of the bottom seams before laying it back in place and frying it all up.

Tomorrow I need to pull the engine back out (again) so I can notch the aluminum rear motor plate. I want it to rest on the floor supports I was working on today when it's done. It's probably futile to say how much will get done when I get up in the morning. I really think I'll be able to finish the floor structure, the body hinges, and the fuel cell support. One thing that was pretty time consuming was capping off each of the cross-members I whacked. I really wish that rotisserie was here. I've been burning the crap out of myself crawling under the chassis and welding.

Nonetheless, I did make further progress today. I started out fabricating a rear transmission mount. I oversized the holes to allow for the transmission to slide forward if I eliminate the 1/4" extra space the rear engine plate uses. I'll use large washers when it's bolted together. I also cut out the last bar that interfered with the future driveshaft.

After finishing the transmission mount I welded in a dropped frame cross-member to take the place of the bar I'd cut out. I fabbed the new cross-member out of 4 45' steel elbows and 3 short sections of 1&1/2" tubing. All welded up it looks like a single bent piece.

After that I went ahead and welded in the driveshaft loop that I made. Having to remove and re-install the transmission several times is starting to scratch up the pretty red paint. - Oh well.

With the loop done I went ahead and welded the 2 straps that the seat bolts down to. They look a little odd but I made them that way on purpose. It's hard to explain, but there's a method to my madness.

The seat is the right height with the roof now. I still need to drill the holes in my brackets so I can bolt it back down.

My next move was to start working on that floor. Rather than cut out the old round cross-members and raise them, I decided to add 1&1/4" square tubing above that would match the height of the original rectangular cross-members & frame. - That way I wouldn't be drilling into (and weakening) the existing cross-members.

I didn't get done before the sun started setting. I only got half of it tacked together. I'll pull these pieces back off and weld any of the bottom seams before laying it back in place and frying it all up.

Tomorrow I need to pull the engine back out (again) so I can notch the aluminum rear motor plate. I want it to rest on the floor supports I was working on today when it's done. It's probably futile to say how much will get done when I get up in the morning. I really think I'll be able to finish the floor structure, the body hinges, and the fuel cell support. One thing that was pretty time consuming was capping off each of the cross-members I whacked. I really wish that rotisserie was here. I've been burning the crap out of myself crawling under the chassis and welding.

Fantastic progress, John!

With your skills, welding a rotisserie together shouldn't take too long. ;)

With your skills, welding a rotisserie together shouldn't take too long. ;)

famous bob

mopar misfit

sounds to me like you get an amazing amount of work done, compared to me anyway !Fantastic progress, John!

With your skills, welding a rotisserie together shouldn't take too long. ;)

1967 'cuda

Dropped on Head as a Baby

Fantastic progress, John!

With your skills, welding a rotisserie together shouldn't take too long. ;)

After seeing one of those roller hoop designs, I decided that's what I would want. The trouble is it would be expensive to build.

Last edited:

1967 'cuda

Dropped on Head as a Baby

sounds to me like you get an amazing amount of work done, compared to me anyway !

You must be moving backwards then bob. LOL. Today really sucked - big time. RAIN! It's really hard working outside when the weather doesn't cooperate.

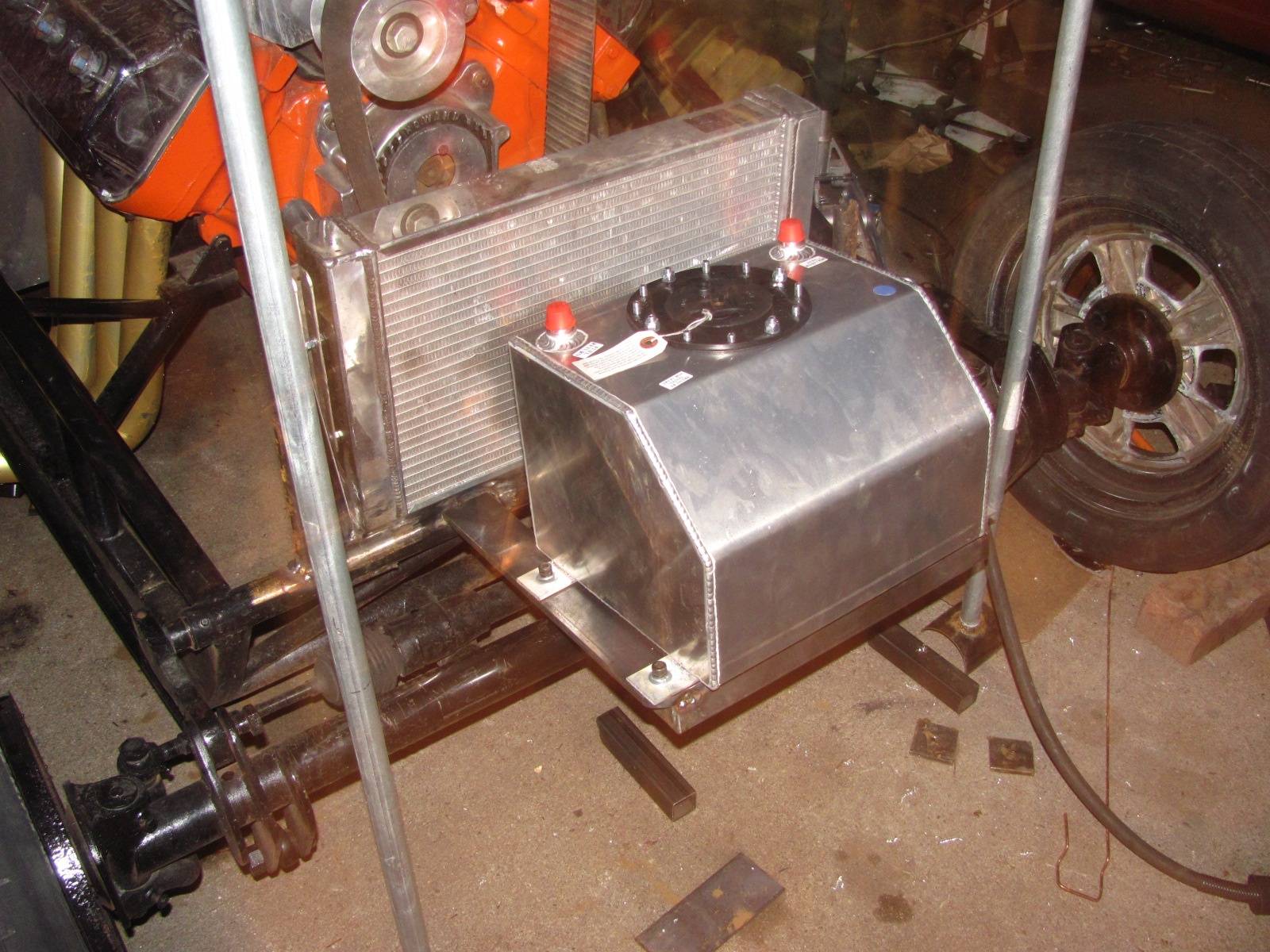

I changed gears today when the fuel cell showed up. Instead of continuing with the floor I decided to work on a mount for it. I got most of the pieces I'll need to finish it but the rain is stopping completion. After it arrived this morning I saw that there wasn't any provision to bolt or strap it down so I managed to have the weld shop do the aluminum welding that I'm not set up to do. I had to remove the foam from the inside first so it wouldn't melt. I cut two straps that are now welded to the bottom. I don't have the edges rounded off yet or the bolt holes drilled.

The supports are still just tacked in place until I can make sure everything fits. Some of those brackets still need to be re-shaped. I realize the structure seems bulky but it will be doing double duty as a location to build the body latch onto.

My radiator only had bottom brackets that allowed too much movement. I cut them off and started fabbing a pair of side brackets to take their place.

It's still raining so I don't know if I'll get any further today. - Keeping my fingers crossed.

Last edited:

SNKEBIT

Spending $$ on Mopars

I have about 150 bucks into my spit. Best money and time I ever spent.

1967 'cuda

Dropped on Head as a Baby

I have about 150 bucks into my spit. Best money and time I ever spent.

Maybe Anders & you will eventually talk me into making one. I keep telling myself that I'd only use it a few times though. I know that whenever I'm crawling under one of these projects I keep wishing I had a rotisserie AND a lift.

Last edited:

1967 'cuda

Dropped on Head as a Baby

Well, the rain let up before dark. I wasn't able to get a lot more done but progress is progress.

My original tank location didn't work. It was too high and too close to the radiator. When I lowered the body it was resting on the top of the tank. After lowering the mount I saw that I still had clearance problems. There's a lateral bar that's part of the body reinforcement. It's right in front of the radiator when the body is lowered. I had to slide the tank forward a few inches to clear it. The new mount I ended up with is somewhat smaller than the original.

I had time to weld up the new radiator support brackets and decided to remove the drums from the front hubs. I found out that front brakes aren't required in the nostalgia class but I still want to put some discs on there along with some spindle-mount wheels. There's a lot of work that eventually will have to be done. I think the rack will need to be replaced.

It was after dark when I stopped and took the photos.

My original tank location didn't work. It was too high and too close to the radiator. When I lowered the body it was resting on the top of the tank. After lowering the mount I saw that I still had clearance problems. There's a lateral bar that's part of the body reinforcement. It's right in front of the radiator when the body is lowered. I had to slide the tank forward a few inches to clear it. The new mount I ended up with is somewhat smaller than the original.

I had time to weld up the new radiator support brackets and decided to remove the drums from the front hubs. I found out that front brakes aren't required in the nostalgia class but I still want to put some discs on there along with some spindle-mount wheels. There's a lot of work that eventually will have to be done. I think the rack will need to be replaced.

It was after dark when I stopped and took the photos.

What's a spit?I have about 150 bucks into my spit. Best money and time I ever spent.

SNKEBIT

Spending $$ on Mopars

Rotiserie... BBQ spit

1967 'cuda

Dropped on Head as a Baby

This morning I got up thinking about taking the funnycar project to a car show in Columbus tomorrow. I didn't know what time it was supposed to start but I knew it was at the Chrysler dealership. I decided to call them for more info. When I asked what time it started on Sunday they told me it was happening today and already in progress.

I had hoped to spend the day getting as far along with the car as I could so it would look more complete. - Instead, I pulled everything that wasn't welded or bolted down and loaded the car. I was in such a hurry that I forgot to take my camera.

I got there a little late which was OK. There was no shade there and everything was on concrete. It got hot.

I wasn't there to get a trophy. What I wanted was to shoot the breeze with fellow Mopar fanatics. As before, the funnycar got a lot of attention. I was happy to find a couple of guys that were transplants from California who were very familiar with McCewen's Duster and also think the body I have is probably one of his old ones. I spent the entire time there swapping stories with current & former drag racers. It was very enjoyable.

On the way home I stopped for some paint that I needed and picked up a few Halloween decorations at Menards. I don't get out of town very often so I also stopped at a Hobby Lobby to see what they had. - Not much for Halloween decorations but I did manage to pick up a couple of tin signs. The Duster sign cost me $5 and the SPEED LIMIT sign cost me $9.

I had hoped to spend the day getting as far along with the car as I could so it would look more complete. - Instead, I pulled everything that wasn't welded or bolted down and loaded the car. I was in such a hurry that I forgot to take my camera.

I got there a little late which was OK. There was no shade there and everything was on concrete. It got hot.

I wasn't there to get a trophy. What I wanted was to shoot the breeze with fellow Mopar fanatics. As before, the funnycar got a lot of attention. I was happy to find a couple of guys that were transplants from California who were very familiar with McCewen's Duster and also think the body I have is probably one of his old ones. I spent the entire time there swapping stories with current & former drag racers. It was very enjoyable.

On the way home I stopped for some paint that I needed and picked up a few Halloween decorations at Menards. I don't get out of town very often so I also stopped at a Hobby Lobby to see what they had. - Not much for Halloween decorations but I did manage to pick up a couple of tin signs. The Duster sign cost me $5 and the SPEED LIMIT sign cost me $9.

-

Similar threads

- Replies

- 4

- Views

- 422