Here's some copy/paste from one of my webpages...

Engine torque is something most car guys think they understand, so giving them torque ratings to compare while clutch shopping preemptively answers a lot of questions. A clutch manufacturers torque rating is just a quick/dirty way for the typical aftermarket clutch buying customer to feel assured that the clutch they buy isn't going to slip against the torque their engine is capable of. From the perspective of the aftermarket clutch manufacturer, if the clutch breaks something else downstream it's not their problem, at least the customer won't come back complaining about a weak clutch. In reality, choosing a clutch is more complicated than just engine torque. To keep your stick shift drivetrain alive, it's important to pay attention to what happens inside the bellhousing.

The T5 5spd serves as a good real-world example. It was an OE transmission for both GM and Ford, and the 2.95 gearsets for both versions are nearly identical as far as case/gear strength. But the GM version of the 2.95 V8 T5 has a reputation as being weak, while it's pretty common to see Ford version of the 2.95 V8 T5 running 10's on the dragstrip with slicks. The difference is the clutches that are commonly used with each version. The GM T5 guys almost always go to the aftermarket and end up with around 2800-2900lbs of clutch clamp from a 10.5" diaphragm, while the go-to clutch for the Ford T5 guys is the Ford Motorsport "King Cobra" 10.5" diaphragm which has 2124lbs of clamp.

The clutch is what brings the engine and chassis together as an efficient dragstrip package. Don't buy a clutch with plans to "grow into it", it is far better to pick one that's the best match for your engine and use. Choosing a clutch is not a situation where too much is just right. Excess torque capacity not only increases the clutch's potential to inflict damage on your drivetrain, but it will also slow you down at the dragstrip. The target should instead be a clutch that slips for a half second or so after a WOT shift into high gear.

It's important to note that aftermarket clutch manufacturers typically rate their clutches conservatively. You can't blame them, as the typical customer doesn't want a clutch that slips, and the manufacturer doesn't want a dissatisfied customer. But if you are serious about not leaving any ET on the table, you need to push beyond those manufacturer ratings.

So how much clutch do you really need? For example, the typical aftermarket GM/Mopar pattern 10.5" diaphragm PP installed out of the box has about 2800lbs of clamp. It's hard to find anything less in the aftermarket, so let's see what 2800lbs of clamp gets you with different types of clutch discs....

...With an organic disc, 2800lbs is ballpark for an engine with around

500ftlbs of torque.

...With a typical dual friction disc, 2800lbs is ballpark for an engine with around

655ftlbs of torque.

...With a typical iron puck disc, 2800lbs is ballpark for an engine with around

810ftlbs of torque.

...With a cerametallic puck disc, 2800lbs is ballpark for an engine with around

820ftlbs of torque.

Let's say your engine puts out 500ftlbs, how much clamp would you then need for a typical dual friction disc? For that you can calculate a percentage of the above ratings. The above says 2800lbs of clamp on a dual friction disc is ballpark for 655ftlbs. If you divide 500 by 655, you get .76 which means you would need 76% of 2800lbs or 2800 x .76 = 2128. In other words, a 500ftlb engine needs about 2128lbs of ballpark clamp on a 10.5" dual friction disc. Good luck finding something close in the aftermarket.

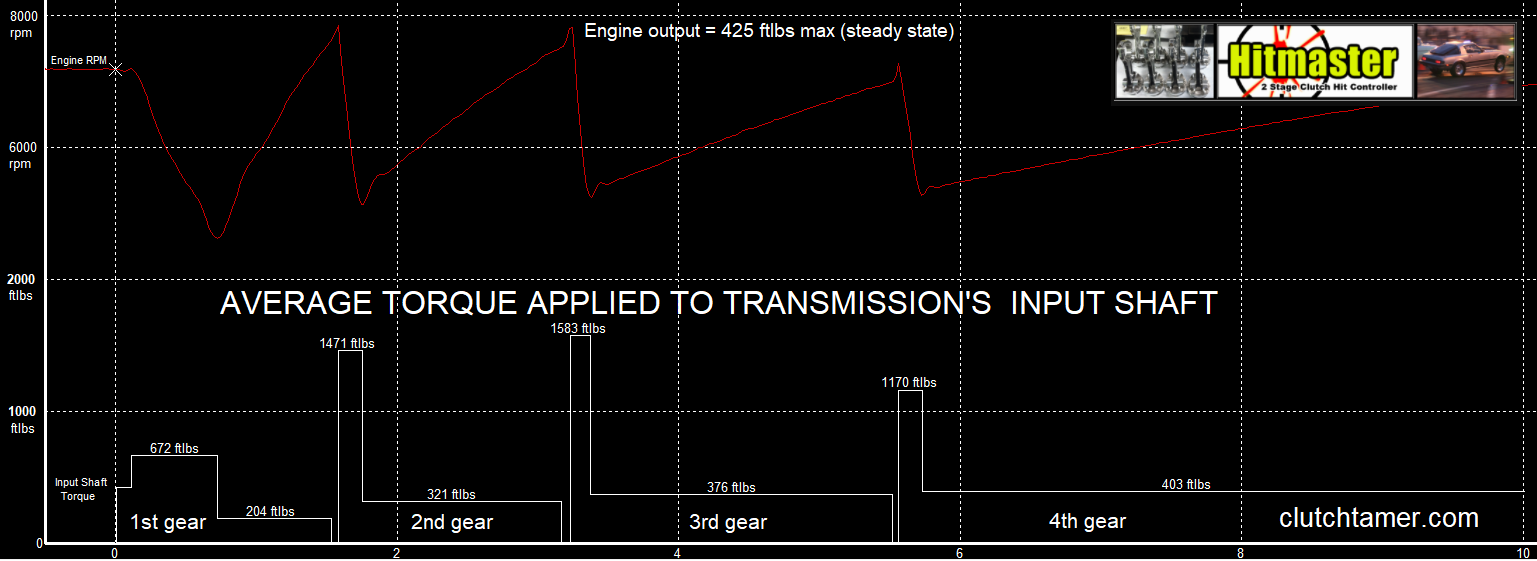

The Racepak graph below is of a dragstrip pass with an engine that puts out around 425ftlbs max WOT steady state, a good example of a car that has too much clutch. I added some averaged binary torque numbers to the lower part of the graph to reflect the calculated torque that the engine applied to the transmission's input shaft during the pass. Note how this 425ftlb engine put out way more than 425ftlbs when it is losing rpm, and much less than 425ftlbs when it is gaining rpm. At no time during this pass was this 425ftlb engine actually sending 425ftlbs to the transmission's input shaft, because at no time during this pass was the engine operating at a constant rpm. The engine was either losing or gaining rpm at every point after launch while it worked its way thru the gears. Note that during the climb in 1st gear, less than half of that engine's potential torque output was actually reaching the transmission's input shaft!

...you might ask-

If this Engine is capable of 425ftlbs, WHERE DID ALL THAT MISSING TORQUE GO???...

Grant