You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bench Testing

- Thread starter 440 Mike

- Start date

-

I didn't test lights and illumination. I guess I had no concerns there other than bulbs and bulb holders.

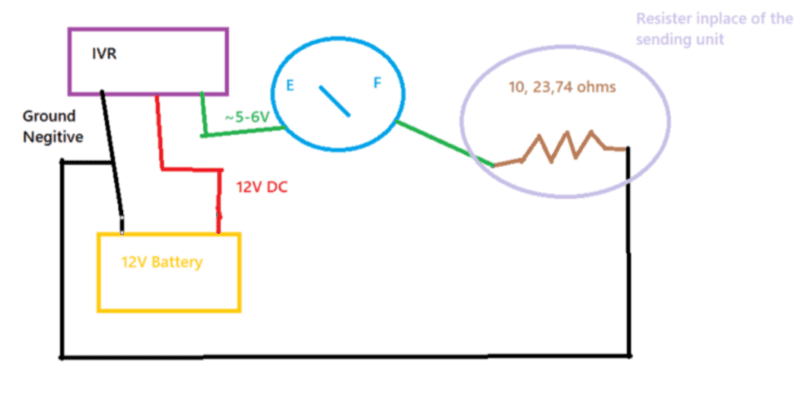

I did test gages using all the methods recommended. First check for resistance in the gage. The used some D Cells in series to check response to 3 or 4.5 volts. Finally hooked up resistors to represent sending unit resistance, and then used a car battery to power the IVR and see how the gages responded to low, mid and high resistance.

www.forabodiesonly.com

www.forabodiesonly.com

I did test gages using all the methods recommended. First check for resistance in the gage. The used some D Cells in series to check response to 3 or 4.5 volts. Finally hooked up resistors to represent sending unit resistance, and then used a car battery to power the IVR and see how the gages responded to low, mid and high resistance.

Gauge Cluster Issues/IVR

I found a replacement oil gauge the guy wants $50 for it. He tested it for continuity. But before I buy it I'm bringing my multi reader. Testing the ohms. I'll see if he will let me pop the lid off it too.

www.forabodiesonly.com

www.forabodiesonly.com

12v power source. (Car battery or DC power supply)

3 resisters

1 watt should be enough for short term testing

10 ohm

23 ohm

73 ohm

Some alligator test leads

A multimeter

Watch and understand this video

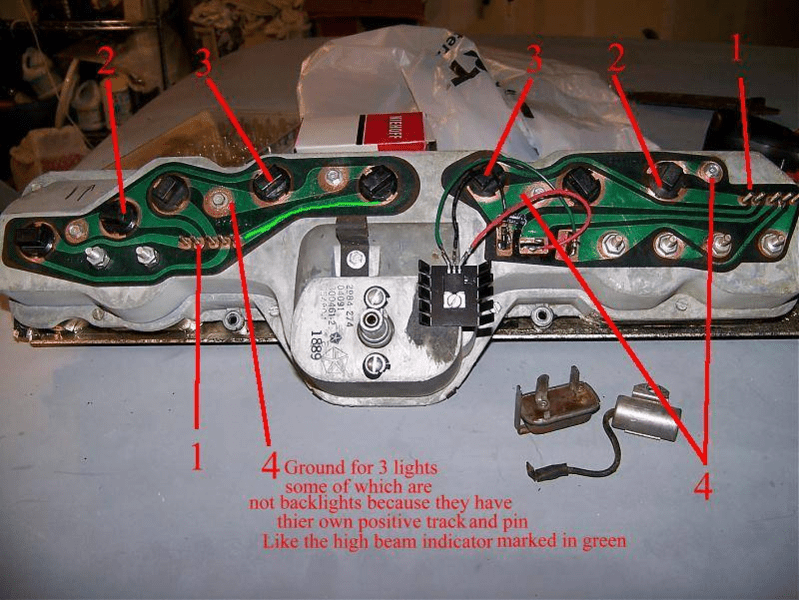

trace out your circuit board so you know what is what.

any trace that has a screw that goes through it is a ground.

hook up the power source negative to a good ground on the cluster

Most bulbs will need positive to a pin on the cir board to illuminate.

3 resisters

1 watt should be enough for short term testing

10 ohm

23 ohm

73 ohm

Some alligator test leads

A multimeter

Watch and understand this video

trace out your circuit board so you know what is what.

any trace that has a screw that goes through it is a ground.

hook up the power source negative to a good ground on the cluster

Most bulbs will need positive to a pin on the cir board to illuminate.

Thanks for the replies. Found this thread to be helpful too.

www.forabodiesonly.com

www.forabodiesonly.com

Bench Testing a gauge cluster

Hey Guys, I did a search on the forums and found similar threads and advice. It was all greek to me. Simple question. How do I power up the backlights on the gauge cluster to test and make sure I have em all oriented right and everything is working right?

www.forabodiesonly.com

www.forabodiesonly.com

Gauge testing

Going well so far. Started out by checking the housing to circuit board trace ground screws, not so good. Removed screws and gave traces the De-Oxit and Q-tip treatment until good continuity on the meter. Next the bulbs and holders. One broken holder, replaced with spare. I'll replace all of the GE 158's when I get some. Cleaned bulb traces and contacts with De-Oxit again, good stuff!

The nuts on the fuel/temp gauge posts were surprisingly loose, age I suppose. Cleaned and got good continuity from the pins to the posts. While gauges were disconnected from the trace they both read about 12.5 ohms. Ammeter nuts were loose on the posts also, cleaned and snugged up.

Flashlight battery test next, then find some resistors.

The nuts on the fuel/temp gauge posts were surprisingly loose, age I suppose. Cleaned and got good continuity from the pins to the posts. While gauges were disconnected from the trace they both read about 12.5 ohms. Ammeter nuts were loose on the posts also, cleaned and snugged up.

Flashlight battery test next, then find some resistors.

Be carefully tightening ( or loosening) the nuts. I destroyed a perfectly good gauge because the nuts twisted the posts.Ammeter nuts were loose on the posts also, cleaned and snugged up

Since then I use two nuts as jam nuts to hold the post tight while loosening / tightening the nuts.

I also had an Ammeter that the posts were twisted enough that the insides were shorted to the housing

-