matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 3,011

- Reaction score

- 1,374

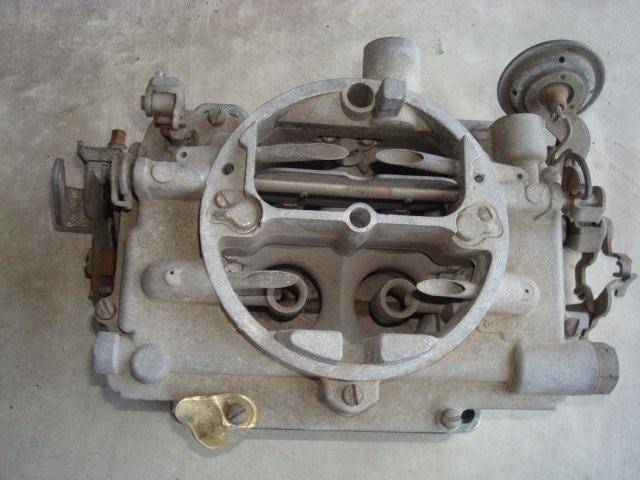

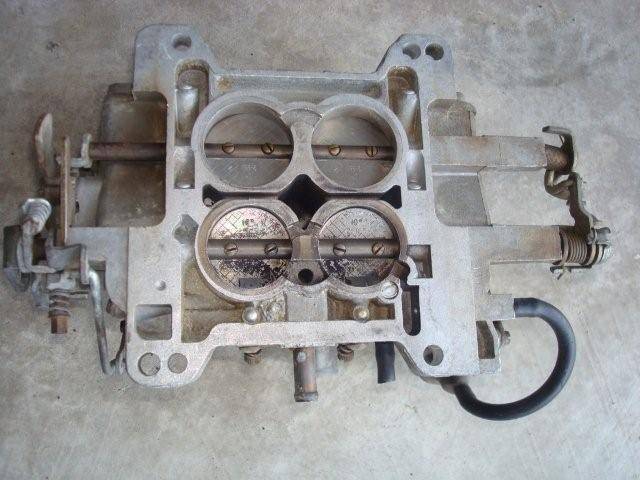

Just got this, where is the best place to get a rebuild kit?

It is a 4298S.

If I was able to rebuild a Holley, would I have any issues with this?

What are they finished in, paint, just the metal?

Anything I need to know with these carbs?

It is a 4298S.

If I was able to rebuild a Holley, would I have any issues with this?

What are they finished in, paint, just the metal?

Anything I need to know with these carbs?