after studying the designs, a picture emerges, the real performance/racing/competition TQ's were the early 1969-72 CS carbs, and the '71 340 carb. but they would not pass 1972-up emissions standards. so they went to the solid fuel design just like a Qjet after '72, so Chrysler, Ford, IHC could use them and be Federal/California legal.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Carter Thermoquads ~ 'More General Information'

- Thread starter 69 Cuda 440

- Start date

-

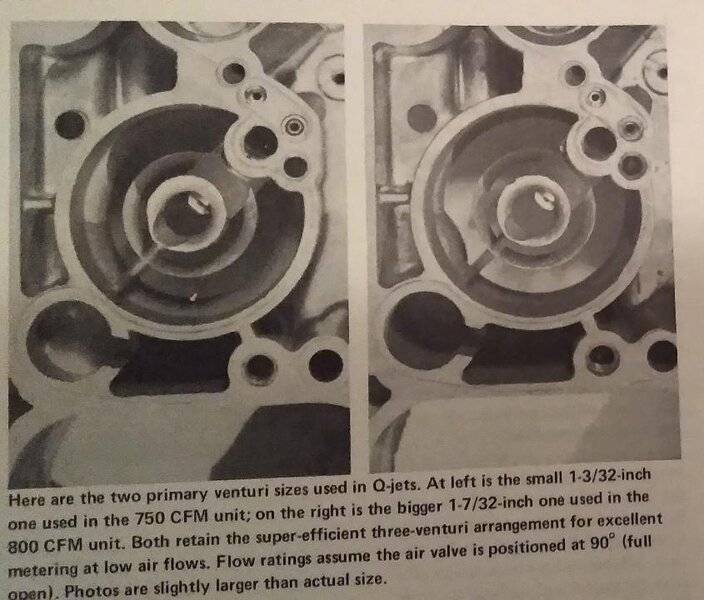

you can tell what Carter did here...the Qjet was the cutting edge of OEM carb technology around 1965. Carter copied, improved it for racing 1969 with the early CS carbs, and changed it to air metered like a Holley. Richer metering for competition, racing. By 1972 the musclecar scene was winding down quickly, so they backpedal the design to what the Qjet was to begin with, and sell it to the OEM's for the next 15+ years. that's where the real money and sales volume was. But this is why most TQ and Qjet carbs can be had under $100 on Ebay all day long- while a real McCoy early CS or 71 340 carb is $500 and up, and the strip kit alone is $475-$500. the air metered carb is the better performer at the track. not to say you can't modify the 72-up carbs to match them- basically what's has to be done with later carbs, is add fuel, take away emulsion/air bleed. richen it up. solid fuel metered is really an emissions designed carb. so were all the Qjets. here's 750 vs. 800cfm Qjet booster, angled upward nozzle, air bleed cluster. there's 6 air bleeds in that cluster, 3 per side. it's a '69 428 Pontiac lid, on a '70 Buick 800cfm center I used, raced since 1985, on 6 different engines. the Qjet did 750/800cfm, Carter took it to 800/850/1000cfm with improved design, added dual feed/floats

Last edited:

those early 69-71 CS and 340 carbs really are worth their weight in gold. If you find one for 500 bucks it's worth it, and you're lucky to even find one for sale at that. they'll probably continue to climb in price. that's if the current economic, political, social climate even allows us to fire up an ICE on gas in the future...I'm starting to have my doubts they even want or will allow us to do that. it's starting to look like we'll need an expensive permit just to idle an engine on a stand in the driveway. but that's another issue....

69 Cuda 440 has passed away. He is now listed as a “Legendary member” for this reason.

One of the reasons he lists the carbs he did was lack of emission items and design on the carb. Also, the lady at would be very long. To include every last desirable carb would be a big task. Missing one or two is easy.

69 CUDA 440 was one helluva remarkable guy. nowhere else on the entire net, are the advertised vs. actual cfm of the carbs listed, like his thread here. I've been perusing this thread for a long, long time- over the years ! I may have an old username long forgotten from an ancient email addy server not even in existence anymore...can't remember....so had to re-register

69 CUDA 440 filled in all the little details that Carter Carbs, and all the so-called big carb building pros, always omitted- or didn't know, or care about. It is extremely valuable, interesting information, that otherwise would have been lost in time. Now it's actually automotive archeology.

I've been reading a lot of TQ tuning threads, and one issue I see time and again is, someone is tuning on a 1972-77 era TQ on their street/strip or race car, and they get the fuel mixture pretty good for idle, but at high rpm it goes rich. IMHO that's either too much emulsion i.e. air bleed, or the air bleed is partially blocked, or completely blocked. or the bowl vents are partially plugged. too much emulsion i.e. air bleed can do crazy things to a carb. it'll delay main metering start and pullover, but at high rpm all that emulsion air acts as a pressure jet and actually starts shooting the fuel through the nozzles into the engine, so it goes rich up top. pig rich like down to 10:1 ratio in some cases at high rpm through traps. this is where the early CS carbs, '71 340 carb shine, they have modest race oriented air bleeds/emulsion, and aren't heavy emission regulating carbs like the later ones. the 1972-74 are the next best thing. as the Federal emissions standards tightened up over the years, they met those laws by adding emulsion and leaning out the metering at idle/off idle/part throttle because that's where most of the daily street driving occurs. but take that same carb and put it on a race car or high performance engine, it can become lean as hell at the bottom end, and rich at the top end. some of the jet sizes I see put in the race car TQ's are like alcohol jet sizes, 50% bigger than what you'd expect. that tells me it's because the air bleeds in the carb top/lid are emission sized and the tuner is trying to overcome that with a bigger and bigger jet. the cure is, get an early top lid with smaller air bleeds, and less emulsion. or...another whole carb 1969-74. one thing that's often overlooked is the air bleed sizes and the richer metered top lid is the key, it contains all the air bleeds, idle jet. if you take the time to look over the design and think about it, they're all basically the same base and center plastic body- the real difference between an emission version and high performance version is the top lid. jets can be easily changed in any of them. air bleeds aren't so easy. for instance the idle circuit air/diminishing air bleeds are at an angle and plugged from the front, or inside the carb bores near venturi. very hard to change sizes without removing those plugs and doing major surgery.

which leads me to a conclusion- if you're looking for a hot rod TQ, you don't even need the whole carb. all you need is the lid. put it on any carb center section with the spec'd rods, jets, float settings, needle valves your combination likes, you're going to be damned close. the lid is in reality, the most valuable part of the entire carb, and the most difficult to reproduce if you don't have an original performance carb. all the centers sections, baseplates are basically identical.

which leads me to a conclusion- if you're looking for a hot rod TQ, you don't even need the whole carb. all you need is the lid. put it on any carb center section with the spec'd rods, jets, float settings, needle valves your combination likes, you're going to be damned close. the lid is in reality, the most valuable part of the entire carb, and the most difficult to reproduce if you don't have an original performance carb. all the centers sections, baseplates are basically identical.

Last edited:

we hear that TQ's after 1974 are leaner, then from another source TQ's after 1975 are leaner, and also from a third source that they're all good up to 1977, etc.

well the truth is always very hard to come by, but is a good thing and very enlightening.

so today I compared a 1972 #6090 TQ 850cfm, to a later model 1977 #9103 TQ 850cfm

the only difference in the description is the later model is labelled "HP" in the Carter Thermo-Quad Guide online. both are for automatic transmission. the drill bit pin hole test and dial calipers don't lie. they may be off a thou now and then, but still a murky image becomes a clear picture.

what I found was, both carb top lids are identical in every way. every single air bleed is the same, even the secondary spray bar discharge holes are drilled exactly the same way. and BTW there's more holes in one side spray bar than the other from the factory, and many different sized holes side to side. they are not the same side to side on secondaries. and they are the same offset on both carbs.

the ONLY difference I can find, is the idle jet tube. the '72 6090 has a .036" idle jet, and the '77 9103 carb has a .034" idle jet. not much but that is noticeably leaner on an idling car.

now the puzzling, perplexing part. we always think the later the carb, the leaner it got. not in this case, the later '77 carb is jetted WAY richer:

'72 6090 had 95 primary/137 secondary jets

'77 9123 had 98 primary/143 secondary jets

here's where the biggest difference was, that leans out the late model '77 carb at midrange/part throttle, the primary metering rods:

'72 6090 has 1937 rods, they are 70-46-40 in thou/inch

'77 9103 has 2211 rods, they are 71.5-64-40 in thou/inch

what's it boil down to ?

the '77 400 HP had .0035" leaner idle mixture, with the fatter rod/smaller idle jet. it also had much leaner by .018" midrange throttle mixture metering area due to the wider rod middle step. just going by rod/jet sizes. not doing the math for actual area.

now the kicker...at wide open throttle, both power tips are .040"- dead nuts even.

the '77 carb has much larger primary/secondary jets, .003" bigger primary, .006" bigger secondary. 3 more jet size primary is a lot bigger. 6 more jet sizes higher on the secondaries, is a real lot more. that's like running a power valve that opens at WOT on a Holley.

and so much for the later carbs having more emissions or being leaner. only a tad leaner at idle, and at midrange/part throttle. if you simply drilled out the idle jet on the '77 carb with a long .036" drill bit, you basically HAVE the '72 carb, and then some- the '77 carb will fuel a larger engine at WOT, with the richer jets, same power tip size metering rods.

the secondary main metering air bleed tubes were identical on both carbs, .040" tubes, drilled through on the bottom, showing two .034" emulsion holes, being drilled through once in and out of the tube horizontally. the diminishing idle air bleeds, primary discharge nozzles, and air bleeds in the nozzle tips are identical.

yes the later carbs are leaner- but only a tad, and only at idle, off idle, part throttle.

at WOT the later carbs very well can be, and are, richer.

so...take the lid from the 6090, with its attached metering rods, and plop it on 9103. you really only need the lid from the early carb.

well the truth is always very hard to come by, but is a good thing and very enlightening.

so today I compared a 1972 #6090 TQ 850cfm, to a later model 1977 #9103 TQ 850cfm

the only difference in the description is the later model is labelled "HP" in the Carter Thermo-Quad Guide online. both are for automatic transmission. the drill bit pin hole test and dial calipers don't lie. they may be off a thou now and then, but still a murky image becomes a clear picture.

what I found was, both carb top lids are identical in every way. every single air bleed is the same, even the secondary spray bar discharge holes are drilled exactly the same way. and BTW there's more holes in one side spray bar than the other from the factory, and many different sized holes side to side. they are not the same side to side on secondaries. and they are the same offset on both carbs.

the ONLY difference I can find, is the idle jet tube. the '72 6090 has a .036" idle jet, and the '77 9103 carb has a .034" idle jet. not much but that is noticeably leaner on an idling car.

now the puzzling, perplexing part. we always think the later the carb, the leaner it got. not in this case, the later '77 carb is jetted WAY richer:

'72 6090 had 95 primary/137 secondary jets

'77 9123 had 98 primary/143 secondary jets

here's where the biggest difference was, that leans out the late model '77 carb at midrange/part throttle, the primary metering rods:

'72 6090 has 1937 rods, they are 70-46-40 in thou/inch

'77 9103 has 2211 rods, they are 71.5-64-40 in thou/inch

what's it boil down to ?

the '77 400 HP had .0035" leaner idle mixture, with the fatter rod/smaller idle jet. it also had much leaner by .018" midrange throttle mixture metering area due to the wider rod middle step. just going by rod/jet sizes. not doing the math for actual area.

now the kicker...at wide open throttle, both power tips are .040"- dead nuts even.

the '77 carb has much larger primary/secondary jets, .003" bigger primary, .006" bigger secondary. 3 more jet size primary is a lot bigger. 6 more jet sizes higher on the secondaries, is a real lot more. that's like running a power valve that opens at WOT on a Holley.

and so much for the later carbs having more emissions or being leaner. only a tad leaner at idle, and at midrange/part throttle. if you simply drilled out the idle jet on the '77 carb with a long .036" drill bit, you basically HAVE the '72 carb, and then some- the '77 carb will fuel a larger engine at WOT, with the richer jets, same power tip size metering rods.

the secondary main metering air bleed tubes were identical on both carbs, .040" tubes, drilled through on the bottom, showing two .034" emulsion holes, being drilled through once in and out of the tube horizontally. the diminishing idle air bleeds, primary discharge nozzles, and air bleeds in the nozzle tips are identical.

yes the later carbs are leaner- but only a tad, and only at idle, off idle, part throttle.

at WOT the later carbs very well can be, and are, richer.

so...take the lid from the 6090, with its attached metering rods, and plop it on 9103. you really only need the lid from the early carb.

Last edited:

Here are my findings with TQs.

[1] The ones used here on Fords [ 9000s ]had a very small sec jet [ some were 0.098", smaller than the pri! ], but the sec air bleed was 0.029", smaller than the more common 0.040". Not 100% sure, but I have come across some US 9000s that had the 029 sec bleed. The smaller bleed will start the system earlier & make it richer through the range, so sec jet not as big?.

[2] I have no idea how/why the jet sizes & sec jet sizes vary so much, no rhyme or reason that I can see. Rich jetting on a 360, lean jetting on a 440.

[3]

The later carbs have larger pri air bleeds, & larger jets to go with them. There are also two air bleeds that are blocked by the brass discharge tube, & these can only be measured by removing the tube. I suspect these may also vary in size & therefore may account for the different pri jet/rod combinations.

[4] Rich secondaries. I will bet this only happens with the 029 sec bleed carbs. Other things that will cause richness is slow opening air valve diaphragm/dashpot. These are decades old now & the rubber goes hard, slowing the release. This slows the AV opening & richens the mixture. I ALWAYS fit a new dashpot when re-building a TQ. AV tension too high also causes rich mid range mixture.

[5] Chr specified sec jets as large as 0.169" for racing [ in the Mopar book ].

[6] I have never found an explanation for the number, position & size of the holes in the sec nozzle bars. For decades, I have been soldering those holes shut & cutting off the bars at an angle, just like the CS carbs. They run great, more consistent fuel delivery & never had a complaint.

[7] I rebuilt a 9333 the other day, off a local Ford 302. It had the pathetic 098 sec jets. BUT the fitting for the dashpot in the base was not a piece of steel tube, it was a brass insert. It had a tiny hole in it, I would estimate 0.010 - 0.015". This would slow down the dashpot opening rate & richen the mixture. To work with the small jet? Has anybody found a US TQ with this brass insert?

[8] Every TQ I have worked on: the sec blades open to about the same angle & the same with the AV. So the smaller sec jets are not related to positions of these two.

[1] The ones used here on Fords [ 9000s ]had a very small sec jet [ some were 0.098", smaller than the pri! ], but the sec air bleed was 0.029", smaller than the more common 0.040". Not 100% sure, but I have come across some US 9000s that had the 029 sec bleed. The smaller bleed will start the system earlier & make it richer through the range, so sec jet not as big?.

[2] I have no idea how/why the jet sizes & sec jet sizes vary so much, no rhyme or reason that I can see. Rich jetting on a 360, lean jetting on a 440.

[3]

The later carbs have larger pri air bleeds, & larger jets to go with them. There are also two air bleeds that are blocked by the brass discharge tube, & these can only be measured by removing the tube. I suspect these may also vary in size & therefore may account for the different pri jet/rod combinations.

[4] Rich secondaries. I will bet this only happens with the 029 sec bleed carbs. Other things that will cause richness is slow opening air valve diaphragm/dashpot. These are decades old now & the rubber goes hard, slowing the release. This slows the AV opening & richens the mixture. I ALWAYS fit a new dashpot when re-building a TQ. AV tension too high also causes rich mid range mixture.

[5] Chr specified sec jets as large as 0.169" for racing [ in the Mopar book ].

[6] I have never found an explanation for the number, position & size of the holes in the sec nozzle bars. For decades, I have been soldering those holes shut & cutting off the bars at an angle, just like the CS carbs. They run great, more consistent fuel delivery & never had a complaint.

[7] I rebuilt a 9333 the other day, off a local Ford 302. It had the pathetic 098 sec jets. BUT the fitting for the dashpot in the base was not a piece of steel tube, it was a brass insert. It had a tiny hole in it, I would estimate 0.010 - 0.015". This would slow down the dashpot opening rate & richen the mixture. To work with the small jet? Has anybody found a US TQ with this brass insert?

[8] Every TQ I have worked on: the sec blades open to about the same angle & the same with the AV. So the smaller sec jets are not related to positions of these two.

that's interesting stuff. I've seen that tiny hole in the feed pipe on baseplate, going to the dashpot hose somewhere before. I may have one of those carbs. the huge jets with the bigger air bleeds combination, that is for emulsion, and emissions reduction. they found that adding emulsion gives a more homogeneous mixture and cleaner burn. it was all done for the sake of meeting emissions standards. we know that a rich mixture gives highest power. maximum power and maximum efficiency and minimum emissions- those are 3 different settings on any carburetor. minimum emissions usually means running on the lean edge, and the least power, or just adequate power. I've been unplugging and blocking EGR valves for 40 years now on my own personal vehicles. every time there's usually a slight gas mileage reduction, but big improvement in part throttle response and drive-ability, because it's richening the mixture at part throttle.

however, more emulsion and, and will, also cause a rich spike at high rpm as well, in certain carb designs. not across the rpm band, just at the very top end. and it creates a real tuning headache. the solution is, reduce the air bleed sizes. Holley 4 barrels are notorious for it. anything beyond .070 idle bleeds, .030" high speed bleeds, in combination begins to cause delayed main metering, lean bottom end, but rich spike at high rpm. the bigger the bleeds get beyond that point, the worse the spike is.

the devices put on cars to meet emissions standards border on downright silly. pushing more exhaust into the intake tract, to dilute and cool the charge. wth ? sure it will pollute less. it will also run less. (laughter..)

we had a 2003 Saturn station wagon that had an electric air pump that ran like a hair dryer, and pumped air into the exhaust manifolds just so the car could meet emissions during cold startups. it was noisy as hell. it also led to repeatedly cracking the exhaust manifolds, because it would cause massive secondary ignition in the exhaust manifold, and overheat it. it cracked 3 times, I replaced it once, and had it welded once- in the life of the car. see they don't mind how they get it, they just need to meet the standard to sell the car. if you can put a big electric motor on the car and pump fresh air from outside into the exhaust stream so it dilutes the exhaust, and the tailpipe emissions go down, presto you met the emissions standards. it's like adding water to beer to get the alcohol content under 3%. but it ends up tasting lousy like watered down beer.

the holes drilled differently on each side of the secondary spray bar nozzles, that was to get even distribution for the oem intake manifolds. there was a guy who actually dyno tested tons of TQ carbs on engines working at Chrysler in the 1970-80's, he posted that it was a real PITA to get those TQ/iron intake combos to have even distribution. If the carb is going on an aftermarket intake manifold, I'd most definitely make both spray bars have even sizes holes.

engineers will add more emulsion, get the engine to run cleaner at idle, off idle, midrange, and not worry about the top end so much. because most of the cars never saw high rpm use in 4 doors, station wagons, pickup trucks, etc. if you remember, TQ's were known for making a lot of noise at WOT, but never really going anywhere from about 1975-onward. hence the name "thermobog". and "quadrabog" for the GM Qjets. they bogged right from the factory. I remember watching Hollywood movies with police chase scenes and you could hear the TQ 4 barrel kicking in and the car could not even turn a tire. basically all the GM, Ford, Mopar cars ran like that from about 1975-onward. a 1979 Trans Am with 400 Pontiac engine and Qjet made a whopping 220HP ?? that was only 20hp more than my old 2003 Monte Carlo 3800 Series II V6 3.8 liter 231cid. by comparison, a 1969-70 Ram Air IV 400 in a GTO or TA made about twice as much HP, and was actually under-rated at 370HP. bone stock examples have dynoed 400HP. It's a sad thing what happened to the American V8 engines. they took the octane and compression away, pushed exhaust into the intake tract with EGR, and choked the exhaust further with a cat converter. then retarded the timing, and pumped fresh air into the exhaust with AIR injection. and leaned the living hell out of the carb to boot, and put very tall gears in the rear axle. they crucified those motors with emissions controls and design compromises, and crappy fuel- for very little real gain in emissions or mileage. it was all a political stunt. it's a wonder they ran at all. looking back now, it was done tongue in cheek. the Feds made them put it all on there. and we took it all back off, and basically drove cars with 2 points less compression and low octane fuel.

however, more emulsion and, and will, also cause a rich spike at high rpm as well, in certain carb designs. not across the rpm band, just at the very top end. and it creates a real tuning headache. the solution is, reduce the air bleed sizes. Holley 4 barrels are notorious for it. anything beyond .070 idle bleeds, .030" high speed bleeds, in combination begins to cause delayed main metering, lean bottom end, but rich spike at high rpm. the bigger the bleeds get beyond that point, the worse the spike is.

the devices put on cars to meet emissions standards border on downright silly. pushing more exhaust into the intake tract, to dilute and cool the charge. wth ? sure it will pollute less. it will also run less. (laughter..)

we had a 2003 Saturn station wagon that had an electric air pump that ran like a hair dryer, and pumped air into the exhaust manifolds just so the car could meet emissions during cold startups. it was noisy as hell. it also led to repeatedly cracking the exhaust manifolds, because it would cause massive secondary ignition in the exhaust manifold, and overheat it. it cracked 3 times, I replaced it once, and had it welded once- in the life of the car. see they don't mind how they get it, they just need to meet the standard to sell the car. if you can put a big electric motor on the car and pump fresh air from outside into the exhaust stream so it dilutes the exhaust, and the tailpipe emissions go down, presto you met the emissions standards. it's like adding water to beer to get the alcohol content under 3%. but it ends up tasting lousy like watered down beer.

the holes drilled differently on each side of the secondary spray bar nozzles, that was to get even distribution for the oem intake manifolds. there was a guy who actually dyno tested tons of TQ carbs on engines working at Chrysler in the 1970-80's, he posted that it was a real PITA to get those TQ/iron intake combos to have even distribution. If the carb is going on an aftermarket intake manifold, I'd most definitely make both spray bars have even sizes holes.

engineers will add more emulsion, get the engine to run cleaner at idle, off idle, midrange, and not worry about the top end so much. because most of the cars never saw high rpm use in 4 doors, station wagons, pickup trucks, etc. if you remember, TQ's were known for making a lot of noise at WOT, but never really going anywhere from about 1975-onward. hence the name "thermobog". and "quadrabog" for the GM Qjets. they bogged right from the factory. I remember watching Hollywood movies with police chase scenes and you could hear the TQ 4 barrel kicking in and the car could not even turn a tire. basically all the GM, Ford, Mopar cars ran like that from about 1975-onward. a 1979 Trans Am with 400 Pontiac engine and Qjet made a whopping 220HP ?? that was only 20hp more than my old 2003 Monte Carlo 3800 Series II V6 3.8 liter 231cid. by comparison, a 1969-70 Ram Air IV 400 in a GTO or TA made about twice as much HP, and was actually under-rated at 370HP. bone stock examples have dynoed 400HP. It's a sad thing what happened to the American V8 engines. they took the octane and compression away, pushed exhaust into the intake tract with EGR, and choked the exhaust further with a cat converter. then retarded the timing, and pumped fresh air into the exhaust with AIR injection. and leaned the living hell out of the carb to boot, and put very tall gears in the rear axle. they crucified those motors with emissions controls and design compromises, and crappy fuel- for very little real gain in emissions or mileage. it was all a political stunt. it's a wonder they ran at all. looking back now, it was done tongue in cheek. the Feds made them put it all on there. and we took it all back off, and basically drove cars with 2 points less compression and low octane fuel.

Last edited:

Bewy, on the subject of the large jets/air bleed sizing, the idle air bleeds and primary main metering bleeds on these 6090 and 9103 top lids are out of sight. the angled rearward and up idle air bleed, that goes down into the venturi area as a diminishing air bleed, will accept approximately an .050" drill bit. .048 is loose, .052 is a no go. there's yet ANOTHER angled down idle air bleed, racing DOWNWARD and rearward, in the bottom of cavity, where the main metering rods go through on the top. that one can't be measured, no room to do so. if the lid is removed from the carb, and carb cleaner sprayed into the idle passage in front bottom of carb lid, you can see those 2 idle air bleeds are tied together, both of them spray fluid. these TQ's have a mongo amount of idle air bleed emulsion. that's why the jets are so huge, in comparison to say a Holley, or Qjet.

then there's the primary metering air bleeds, facing straight up on the lid, just forward of the screw hole, that holds the little cover plates over the air bleed/metering rod holes area on each side. remove that plate, check out the size of those bleeds. they go directly down into the main well that feeds the primary nozzles/booster. those primary metering air bleeds are .077' on the 9103, and .087" on the 6090. massive.

there's yet another air bleed in the top nose of each primary nozzle. this is why they needed anywhere from a 92 to 104 main jet. there's a ton of air being used for emulsion and atomization on these carbs. it's really over the top.

again, the later 9103 carb has a smaller primary main metering bleed by about .010"

so it would be richer.

I had thought it was identical but it's not. I do not have a complete drill index in .001" increments.

then there's the primary metering air bleeds, facing straight up on the lid, just forward of the screw hole, that holds the little cover plates over the air bleed/metering rod holes area on each side. remove that plate, check out the size of those bleeds. they go directly down into the main well that feeds the primary nozzles/booster. those primary metering air bleeds are .077' on the 9103, and .087" on the 6090. massive.

there's yet another air bleed in the top nose of each primary nozzle. this is why they needed anywhere from a 92 to 104 main jet. there's a ton of air being used for emulsion and atomization on these carbs. it's really over the top.

again, the later 9103 carb has a smaller primary main metering bleed by about .010"

so it would be richer.

I had thought it was identical but it's not. I do not have a complete drill index in .001" increments.

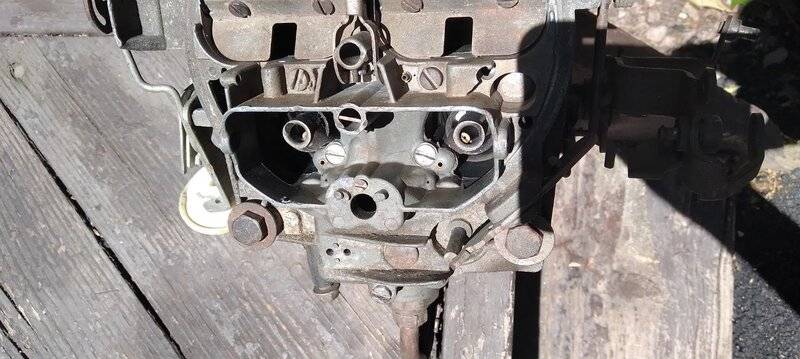

posting some pics for clarity

air bleed area to lid of carb, drill bits and paper clip in bleeds:

shiny bit is the primary main metering bleed around .087"

black bit is upper idle air bleed around .050"

paper clip is lower idle air bleed- just to show where it is

the bleed with nothing in it, is the rear secondary main air bleed, it's .040" measured yesterday

just back from the shiny bit, is the threaded hole for cover plate

air bleed area to lid of carb, drill bits and paper clip in bleeds:

shiny bit is the primary main metering bleed around .087"

black bit is upper idle air bleed around .050"

paper clip is lower idle air bleed- just to show where it is

the bleed with nothing in it, is the rear secondary main air bleed, it's .040" measured yesterday

just back from the shiny bit, is the threaded hole for cover plate

the 2 idle air bleeds in the lid top, meet in the same passage along with idle fuel from the idle jet tube,

the air bleed passage comes together into one passage, and exits in the primary venturi area here,

this is the diminishing air bleed exit. air passes through this bleed at low speeds, and fuel comes out at very high rpm, thereby short circuiting and shutting off idle fuel at the baseplate discharge holes/slots.

the air bleed passage comes together into one passage, and exits in the primary venturi area here,

this is the diminishing air bleed exit. air passes through this bleed at low speeds, and fuel comes out at very high rpm, thereby short circuiting and shutting off idle fuel at the baseplate discharge holes/slots.

secondary discharge bars/nozzle showing unevenly drilled holes for discharge. I believe they can at least be made even both sides in number of holes and size, if the carb is on an aftermarket hi-perf aluminum intake manifold, tunnel ram, high rise, etc. the emulsion tubes for secondary jets on each side, with the .034" holes drilled through them.

etc.

etc.

front primaries have idle jets inside main well, sharing main well with the fuel going to the primary front nozzles. this '72 carb had .034" idle jets. secondary main well has air bleed emulsion protruding downward. secondary rear jets are removed. one thing is certain, there's a lot more air bleed area than fuel jet area, in the front primaries. hence the 95-100 primary main jet sizes. there's a sick amount of air emulsion/bleed/atomization in the primaries of a 72-up TQ carb.

.034" idle jets

.034" idle jets

Thermoquad primary jet sizes

Jet # Size

120-330 .077

120-331 .080

120-332 .083

120-333 .086

120-334 .089

120-335 .092

120-3074 .074

120-3077 .077

120-3080 .080

120-3083 .083

120-3086 .086

120-3089 .089

120-3092 .092

120-4092 .092 *

120-4095 .095 *

120-4097 .097

120-4098 .098 *

120-4099 .099

120-4100 .100 *

120-4101 .101 *

120-4104 .104 *

as you can see, the smallest jet for a TQ, is a huge jet for a Qjet carb

Jet # Size

120-330 .077

120-331 .080

120-332 .083

120-333 .086

120-334 .089

120-335 .092

120-3074 .074

120-3077 .077

120-3080 .080

120-3083 .083

120-3086 .086

120-3089 .089

120-3092 .092

120-4092 .092 *

120-4095 .095 *

120-4097 .097

120-4098 .098 *

120-4099 .099

120-4100 .100 *

120-4101 .101 *

120-4104 .104 *

as you can see, the smallest jet for a TQ, is a huge jet for a Qjet carb

Qjets have a fixed secondary jet orifice of about .125"

the TQ is still somewhat bigger, and more adjustable with removable jets- below.

theoretically on paper, a TQ will feed a bigger engine, to a higher rpm.

Jet # Size

120-339 .110

120-340 .113

120-341 .116

120-342 .119

120-343 .122

120-344 .125

120-3113 .113

120-3116 .116

120-3119 .119

120-3122 .122

120-3125 .125

120-3128 .128

120-3131 .131

120-5110 .110

120-5125 .125

120-5131 .131 *

120-5137 .137 *

120-5143 .143 *

120-5149 .149 *

the TQ is still somewhat bigger, and more adjustable with removable jets- below.

theoretically on paper, a TQ will feed a bigger engine, to a higher rpm.

Jet # Size

120-339 .110

120-340 .113

120-341 .116

120-342 .119

120-343 .122

120-344 .125

120-3113 .113

120-3116 .116

120-3119 .119

120-3122 .122

120-3125 .125

120-3128 .128

120-3131 .131

120-5110 .110

120-5125 .125

120-5131 .131 *

120-5137 .137 *

120-5143 .143 *

120-5149 .149 *

interesting shootout results last year,

from the Don Terrill forum message board

Thermoquad vs. Qjet vs. Holley on a 482cid big block Buick:

Dyno test results - Holley vs Thermoquad vs Quadrajet - Don Terrill’s Speed-Talk

Dyno test results - Holley vs Thermoquad vs Quadrajet

Post by 70GS455 » Thu Feb 04, 2021 12:18 pm

So i got some semi final dyno results from my 482 BBB. Its semi final because we didnt finish, a mechanical failure prevented me from testing one last carb. But will finish in the coming spring. To recap and clarify, used a 950 Holley Ultra HP 0-80805, an Everyday Performance prepped Stage 2 800 cfm Qjet and a "950" Thermoquad, modified by Steve Stills and final tuned by me. The Tquad is called "950" (by me) for lack of any better label. It started out life as an OEM 6322 production 850 with 1.5" pri butterflies, but the primaries were modified by removing the stock 1.186" bowl venturis, opening them up to almost 1.4" and removing one booster ring (the idea is to get close to a 1000 CS Tquad using the more available fuel-metered cores)

All 3 were without any air cleaner base or air turbine, choke flap hardware was removed.

This was with a dual plane manifold. I am definitely intake challenged as manifold vacuum was over 2" with both spreadbores.

Holley 595 hp, 622 ft lb

Tquad 590 hp, 608 ft lb

Qjet 586 hp, 609 ft lb

from the Don Terrill forum message board

Thermoquad vs. Qjet vs. Holley on a 482cid big block Buick:

Dyno test results - Holley vs Thermoquad vs Quadrajet - Don Terrill’s Speed-Talk

Dyno test results - Holley vs Thermoquad vs Quadrajet

Post by 70GS455 » Thu Feb 04, 2021 12:18 pm

So i got some semi final dyno results from my 482 BBB. Its semi final because we didnt finish, a mechanical failure prevented me from testing one last carb. But will finish in the coming spring. To recap and clarify, used a 950 Holley Ultra HP 0-80805, an Everyday Performance prepped Stage 2 800 cfm Qjet and a "950" Thermoquad, modified by Steve Stills and final tuned by me. The Tquad is called "950" (by me) for lack of any better label. It started out life as an OEM 6322 production 850 with 1.5" pri butterflies, but the primaries were modified by removing the stock 1.186" bowl venturis, opening them up to almost 1.4" and removing one booster ring (the idea is to get close to a 1000 CS Tquad using the more available fuel-metered cores)

All 3 were without any air cleaner base or air turbine, choke flap hardware was removed.

This was with a dual plane manifold. I am definitely intake challenged as manifold vacuum was over 2" with both spreadbores.

Holley 595 hp, 622 ft lb

Tquad 590 hp, 608 ft lb

Qjet 586 hp, 609 ft lb

You can look at that shootout many different ways..

why have a spreadbore, when a Holley makes the most HP

why have a Holley, if a junkyard 800cfm Qjet makes only 9HP less.

a TQ really is a slightly better Qjet, but you need the 1000cfm model to get it.

stop fiddling with spreadbores, just buy the 950 HP, and happy motoring

they're all within a tenth in e.t. of each other, run whatever one you have and like...

or ?

why have a spreadbore, when a Holley makes the most HP

why have a Holley, if a junkyard 800cfm Qjet makes only 9HP less.

a TQ really is a slightly better Qjet, but you need the 1000cfm model to get it.

stop fiddling with spreadbores, just buy the 950 HP, and happy motoring

they're all within a tenth in e.t. of each other, run whatever one you have and like...

or ?

Would be interesting to see the difference in economy between the three. With fuel prices these days, fuel economy is a factor for street driven vehicles.You can look at that shootout many different ways..

why have a spreadbore, when a Holley makes the most HP

why have a Holley, if a junkyard 800cfm Qjet makes only 9HP less.

a TQ really is a slightly better Qjet, but you need the 1000cfm model to get it.

stop fiddling with spreadbores, just buy the 950 HP, and happy motoring

they're all within a tenth in e.t. of each other, run whatever one you have and like...

or ?

-

Similar threads

- Replies

- 43

- Views

- 2K

- Replies

- 24

- Views

- 744

- Replies

- 107

- Views

- 3K

- Replies

- 7

- Views

- 2K