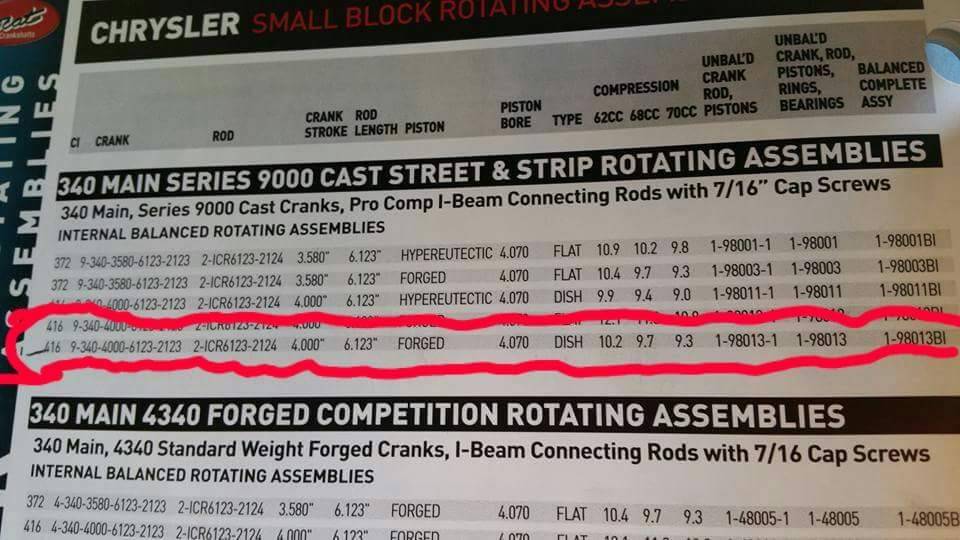

Building a 416 stroker motor from a 1973 block using the scat pak assembly (see pic), lunatic voodoo cam 494/513 lift with 226/234 duration, eldelbrock performer heads giving the motor about a 9:9 compression.

Anyway at a mopar show and swap over the weekend, I found a 72 to 73 cast intake for decent money and with the help of another guy there he said there was not much difference between the cast intake and the aftermarket aluminum intakes. The cast has the EGR holes inside the intake but is not fully set up for EGR.

After the purchase, I took it to my machine shop guy and he claims a 20 horsepower difference between cast and aluminum with the heads I'm using. Opinions anyone.

Anyway at a mopar show and swap over the weekend, I found a 72 to 73 cast intake for decent money and with the help of another guy there he said there was not much difference between the cast intake and the aftermarket aluminum intakes. The cast has the EGR holes inside the intake but is not fully set up for EGR.

After the purchase, I took it to my machine shop guy and he claims a 20 horsepower difference between cast and aluminum with the heads I'm using. Opinions anyone.