1967 'cuda

Dropped on Head as a Baby

From this angle the modifications to the intake and blower are almost invisible.

Another shot of the engine with the new front cover, alternator, distributor, and oil pan.

New side view shot of the motor with the new extras on it.

This is a 'before' picture of the headlights on the Charger. We purchased a set of halogens to replace these at the Wahoo swap meet.

The rear of the new lights were too large to fit into the headlight buckets. I had to enlarge the opening in the buckets by about 1/4" diameter. The headlight rings were also too small in diameter and I had to split the rings to make them fit over the new lights. The molded tangs that were on the new lens housings were too large to fit into the recesses in the buckets, so I ground them down.

New fenders from AMD. - They're not aligned yet but transferred the small parts from the originals and hung them.

For Christmas I picked up some tool boxes for Spence.

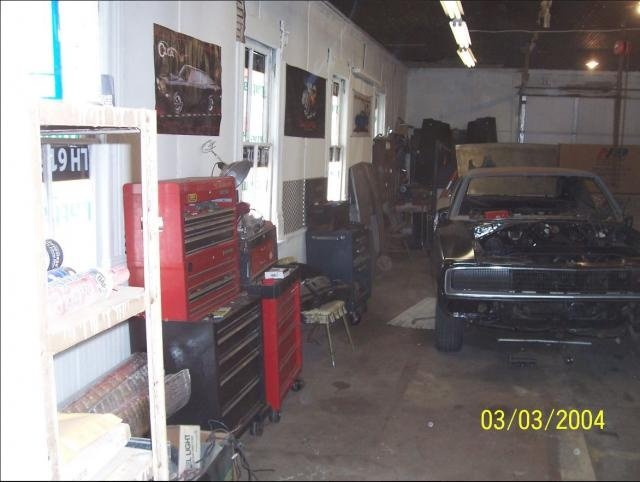

I white-washed the walls to try to make the inside of the shop a little brighter. While I was at it I re-organized the tools and parts.

Winter just never seemed to end and it really slowed production down on the car. It doesn't look that much different now than it did six months ago.

Another picture of the re-organized shop.

Another shot of the engine with the new front cover, alternator, distributor, and oil pan.

New side view shot of the motor with the new extras on it.

This is a 'before' picture of the headlights on the Charger. We purchased a set of halogens to replace these at the Wahoo swap meet.

The rear of the new lights were too large to fit into the headlight buckets. I had to enlarge the opening in the buckets by about 1/4" diameter. The headlight rings were also too small in diameter and I had to split the rings to make them fit over the new lights. The molded tangs that were on the new lens housings were too large to fit into the recesses in the buckets, so I ground them down.

New fenders from AMD. - They're not aligned yet but transferred the small parts from the originals and hung them.

For Christmas I picked up some tool boxes for Spence.

I white-washed the walls to try to make the inside of the shop a little brighter. While I was at it I re-organized the tools and parts.

Winter just never seemed to end and it really slowed production down on the car. It doesn't look that much different now than it did six months ago.

Another picture of the re-organized shop.

Last edited: