1967 'cuda

Dropped on Head as a Baby

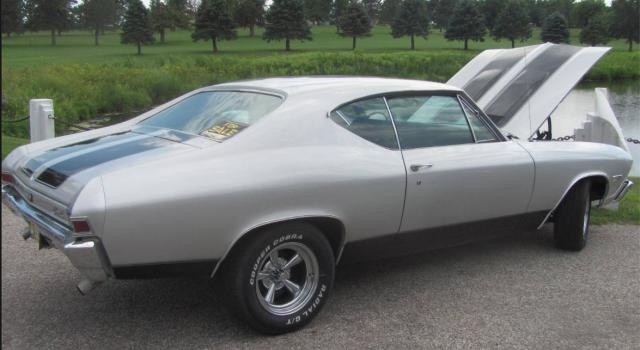

I originally posted the pictures of our 1968 Charger project in the Member Photo Gallery section, but thought maybe I should have put them here instead. I've been a gearhead all of my life. My son Spencer never expressed any interest in cars until after he joined the Army. When he graduated basics he came home and told me that he wanted to buy a Chevelle.

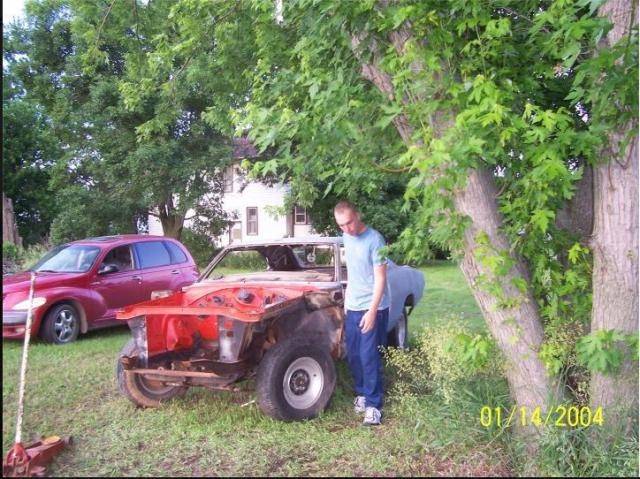

Although I tend to lean heavily towards Chrysler products (I've owned Chevys too) I was thrilled that he wanted a muscle car. We bought a 1968 SS clone big block and we drove it from Nebraska to his base in Georgia. After his first tour of Iraq he told me he really wanted to find a '68 Charger R/T that we could fix up. So we searched across the country for a candidate to restore when he came home on leave again. We didn't have much time to find a car he could afford, and we knew we were most likely going to have to travel to pick one up. That would take time too. He saw one advertized down in Oklahoma but there were no pictures of it. The guy told him it was rust free, straight, and in primer. It would take us a day to get there and we didn't have time to mess around. So we borrowed a friend's truck figuring that we'd rent a trailer after we got down there if the car was acceptable. Ignore the date stamps on the pictures, - they're inaccurate.

Thought I'd upload a few pictures of the Charger as it looked when we first got it back from Oklahoma. - Before the work began. Although we weren't sure what the body was like beneath the primer, there were indications of bondo all over. Previous owner claimed body was really straight and rust free. yeah, right.

We had borrowed Bill Wenske's truck to make the journey. The U-HAUL trailer rented in Oklahoma worked great.

[

photo you can see how twisted/melted it was. The front blinkers were melted too.

photo you can see how twisted/melted it was. The front blinkers were melted too.

Tires and wheels were scabs put on it just to get it to roll. Keep in mind there was no engine, transmission, drive shaft, radiator, usable interior, or almost anything else other than the shell. Half of the brake hardware was missing. Windshield was starting to fog around the edges. It was hard to find a whole lot of positive things to say about the car. But, serial numbers confirm that it is a true RT. Or at least what's left of one.

too bad we didn't get the factory wheel with the car. - as you can see it had air conditioning and it's needing a whole lot of TLC

inside rear shot shows surface rust, but is solid

Spence, Spence, Spence, I can\t wait for you to come home and start working on the car again

1st day we took off the doors, fenders, trunk, hood, bumpers, tail lights, glass, grill assembly cleaned out the rotted interior (carpet and headliner)and then took it to the car wash to try to get the smell out of the car

demolition was a lot faster than reassembly will be

Although I tend to lean heavily towards Chrysler products (I've owned Chevys too) I was thrilled that he wanted a muscle car. We bought a 1968 SS clone big block and we drove it from Nebraska to his base in Georgia. After his first tour of Iraq he told me he really wanted to find a '68 Charger R/T that we could fix up. So we searched across the country for a candidate to restore when he came home on leave again. We didn't have much time to find a car he could afford, and we knew we were most likely going to have to travel to pick one up. That would take time too. He saw one advertized down in Oklahoma but there were no pictures of it. The guy told him it was rust free, straight, and in primer. It would take us a day to get there and we didn't have time to mess around. So we borrowed a friend's truck figuring that we'd rent a trailer after we got down there if the car was acceptable. Ignore the date stamps on the pictures, - they're inaccurate.

Thought I'd upload a few pictures of the Charger as it looked when we first got it back from Oklahoma. - Before the work began. Although we weren't sure what the body was like beneath the primer, there were indications of bondo all over. Previous owner claimed body was really straight and rust free. yeah, right.

We had borrowed Bill Wenske's truck to make the journey. The U-HAUL trailer rented in Oklahoma worked great.

[

Tires and wheels were scabs put on it just to get it to roll. Keep in mind there was no engine, transmission, drive shaft, radiator, usable interior, or almost anything else other than the shell. Half of the brake hardware was missing. Windshield was starting to fog around the edges. It was hard to find a whole lot of positive things to say about the car. But, serial numbers confirm that it is a true RT. Or at least what's left of one.

too bad we didn't get the factory wheel with the car. - as you can see it had air conditioning and it's needing a whole lot of TLC

inside rear shot shows surface rust, but is solid

Spence, Spence, Spence, I can\t wait for you to come home and start working on the car again

1st day we took off the doors, fenders, trunk, hood, bumpers, tail lights, glass, grill assembly cleaned out the rotted interior (carpet and headliner)and then took it to the car wash to try to get the smell out of the car

demolition was a lot faster than reassembly will be

Last edited: