I’m having a problem with my 73 duster clutch pedal. Here’s what I’ve got going. I’ve got a 1970 Plymouth duster that I converted from an automatic to a 4 speed 833. I’ve already done all the converting like stud ball on the frame and the transmission. I’ve got the z bar in along with all the plastic bushings that go on the ball studs and all the stuff on the linkages. I bought a kit with everything to rebuild the linkage. So I know all that is good. My problem is, when I push the clutch in it will go all the way to the floor just as it should but when I let off of it, it will only come back up halfway. Then I have to pull it the rest of the way back up with my foot. It’s almost like it’s got a spot about halfway up that it sticks. When I pull up on it just a little bit it will pop all the way back up. I thought it might have been my linkage but if I unhook the linkage it still does the same thing. Do all 4 speed clutch pedals stick like this? Any advice would be greatly appreciated. Thanks in advance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clutch pedal sticks

- Thread starter bradford

- Start date

-

Professor Fate

Push the button, Max...

Two things come to mind:

1.) If you are using a diaphragm clutch, you need to remove the over center spring on your pedal linkage. These linkages were designed for Borg and Beck, or Long style pressure plates.

2.) Did you also install the correct clutch fork return spring? It's often forgotten.

1.) If you are using a diaphragm clutch, you need to remove the over center spring on your pedal linkage. These linkages were designed for Borg and Beck, or Long style pressure plates.

2.) Did you also install the correct clutch fork return spring? It's often forgotten.

Inertia

Well-Known Member

If the z-bar is installed backwards, or the spring clip missed it's groove, the downrod will bind on the sides of the firewall hole.

With headers the z-bar often needs to be "adjusted" to fit between the 2 upper tubes on the collector, or it will bind.

Good luck

With headers the z-bar often needs to be "adjusted" to fit between the 2 upper tubes on the collector, or it will bind.

Good luck

Assuming the clutch is adjusted properly now, yes remove the spring.Yes it has the diaphragm clutch on it and the return spring is installed. So do I need to remove the big spring on the clutch pedal?

Washers between the coils make it easier to remove in the car.

Super-Cuda

MOPAR .. Move Over, Plymouth Approaching Rapidly!

Also, get a very mild spring and secure it to the clutch pedal down below on the linkage to ensure the pedal doesn’t ride on the throw out bearing at rest.Neat trick with the washers. Thanks

I’ll remove the spring on the clutch pedal and I’ll let everyone know if it works. Thanks again for all your help

sinitro

Member

Make sure U are using the correct Z-bar..

Various Mopar Z-bars have the same width but the mounted tab that pushes the adjusting rod to the fork is not aligned properly, and this makes the pushback angle off-center. The adjusting rod should be parallel to the bell housing..

Just my $0.02...

Various Mopar Z-bars have the same width but the mounted tab that pushes the adjusting rod to the fork is not aligned properly, and this makes the pushback angle off-center. The adjusting rod should be parallel to the bell housing..

Just my $0.02...

Daves69

Well-Known Member

FWIW, The OC spring works in both directions of the pedal with a B&B setup.My problem is, when I push the clutch in it will go all the way to the floor just as it should but when I let off of it, it will only come back up halfway. Then I have to pull it the rest of the way back up with my foot. It’s almost like it’s got a spot about halfway up that it sticks.

Pushing the pedal down, the OC spring assists you (your leg) in compressing the plate springs to release the disc once its "over center".

As you let off the pedal the OC spring lifts the pedal up to the stop once the plate springs have pushed it back "over center".

Let us know where your pedal rests after you remove the OC spring.I’ll remove the spring on the clutch pedal and I’ll let everyone know if it works. Thanks again for all your help

Dave999

Well-Known Member

depending on car and bellhousing the inner z bar ball stud is usually on a mount to off set it from the 2 bolts that hold it onto the bell housing.

on my car its a J shaped hunk of steel with the ball stud screwed into the curly end of the j

To be honest i have no idea if the same mount is used on US A body cars....i'm assuming it probably is

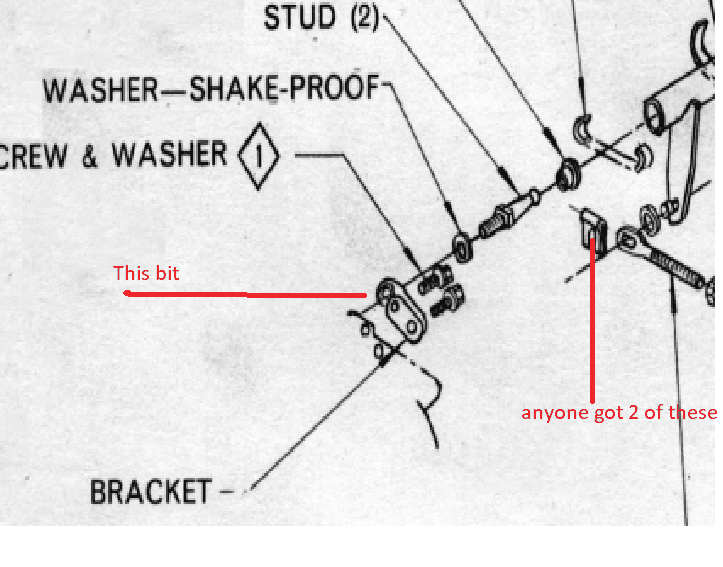

see example here

**HEMI 6 BELLHOUSING PIVOT ARM**VALIANT CHARGER CHRYSLER** 265 HEMI | eBay

this can be mounted two ways

upright of J facing forward and the end facing up towards gearbox

Or upright of J facing backwards and curve of J facing down and towards the motor

if you put it on the wrong way

1) the z bar is out of alignment and clutch adjustment nut and washer are very close to the head of the adjuster rod

2) the linkage from clutch peddle and the linkage from Z bar to clutch fork sit perfectlyy when the clutch is not pressed. but absolutely mangle the wave clips that hold the linkage togther at the upper and lower z bar studs when it binds on the way to clutch peddle down and on the way back up to clutch peddle up.

The z bar will allways be a little bit wonky due to differences in the front engine mount insulators and the fact that the factory seemed to be a bit crap at getting the chassis ball in exactly the right place. this usually amounts to a minor, one end higher than the other situation, BUT if the inner mount is back to front the z bar is no longer parallel with the floor and no longer parrallel with the bulkhead, in a noticable way, when under the car. wrong in 2 dimensions at the same time.

stuff i have seen

1) trying to use the e body adjuster rod with the offset head. (works in the middle of travel but pops the clip off at the extremes)

2) bending and twisting the lower arm of the z bar to make the flat steel arm parrallel with the threaded secction of the adjuster rod

when all that was needed was to get the bell housing mount the right way round

see attached apologies about labelling pic was captured for a wanted advert and just to confuse matters its from a right hand drive service manual all the same stuff though....

all the same stuff though....

Dave

on my car its a J shaped hunk of steel with the ball stud screwed into the curly end of the j

To be honest i have no idea if the same mount is used on US A body cars....i'm assuming it probably is

see example here

**HEMI 6 BELLHOUSING PIVOT ARM**VALIANT CHARGER CHRYSLER** 265 HEMI | eBay

this can be mounted two ways

upright of J facing forward and the end facing up towards gearbox

Or upright of J facing backwards and curve of J facing down and towards the motor

if you put it on the wrong way

1) the z bar is out of alignment and clutch adjustment nut and washer are very close to the head of the adjuster rod

2) the linkage from clutch peddle and the linkage from Z bar to clutch fork sit perfectlyy when the clutch is not pressed. but absolutely mangle the wave clips that hold the linkage togther at the upper and lower z bar studs when it binds on the way to clutch peddle down and on the way back up to clutch peddle up.

The z bar will allways be a little bit wonky due to differences in the front engine mount insulators and the fact that the factory seemed to be a bit crap at getting the chassis ball in exactly the right place. this usually amounts to a minor, one end higher than the other situation, BUT if the inner mount is back to front the z bar is no longer parallel with the floor and no longer parrallel with the bulkhead, in a noticable way, when under the car. wrong in 2 dimensions at the same time.

stuff i have seen

1) trying to use the e body adjuster rod with the offset head. (works in the middle of travel but pops the clip off at the extremes)

2) bending and twisting the lower arm of the z bar to make the flat steel arm parrallel with the threaded secction of the adjuster rod

when all that was needed was to get the bell housing mount the right way round

see attached apologies about labelling pic was captured for a wanted advert and just to confuse matters its from a right hand drive service manual

Dave

Last edited:

Just wanted to let everyone know. I checked everything like the linkage and z bar etc. Everything was just as it should be so the next thing was removing the over center spring, which I done and that was it. The clutch works great now. Thanks for the info.

Go to a home improvement store and buy a package of builders shims. Have someone hold the pedal down while you stick a few shims between the coils. You'll probably have to break them off to get them out of your way. When the pedal is released the spring will come right off. Leave them in there in case you ever want to put it back on.I’m having a problem with my 73 duster clutch pedal. Here’s what I’ve got going. I’ve got a 1970 Plymouth duster that I converted from an automatic to a 4 speed 833. I’ve already done all the converting like stud ball on the frame and the transmission. I’ve got the z bar in along with all the plastic bushings that go on the ball studs and all the stuff on the linkages. I bought a kit with everything to rebuild the linkage. So I know all that is good. My problem is, when I push the clutch in it will go all the way to the floor just as it should but when I let off of it, it will only come back up halfway. Then I have to pull it the rest of the way back up with my foot. It’s almost like it’s got a spot about halfway up that it sticks. When I pull up on it just a little bit it will pop all the way back up. I thought it might have been my linkage but if I unhook the linkage it still does the same thing. Do all 4 speed clutch pedals stick like this? Any advice would be greatly appreciated. Thanks in advance.

-