55 sounds right on the money!Cragar states, 55 for 7/16" 65 for 1/2"

You all can crank them to 70-100 if you want

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cragar SS lug nut trouble

- Thread starter Asher Bird-Meyer

- Start date

-

HemiSSDart

Dartus Interuptus

Yes, we have been through this before, Summit has a misprint and it is for sure 11/16...Yes, after I read your post I went out to my garage and checked mine. They take an 11/16 socket. Either the Summit spec sheet has a misprint or that is not the right part number. I'm trying to find my old receipt for the lug nuts, but so far have not located it.

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 3,755

- Reaction score

- 2,838

I bought sbp Cragar lug nuts 100 years ago, nice pieces.

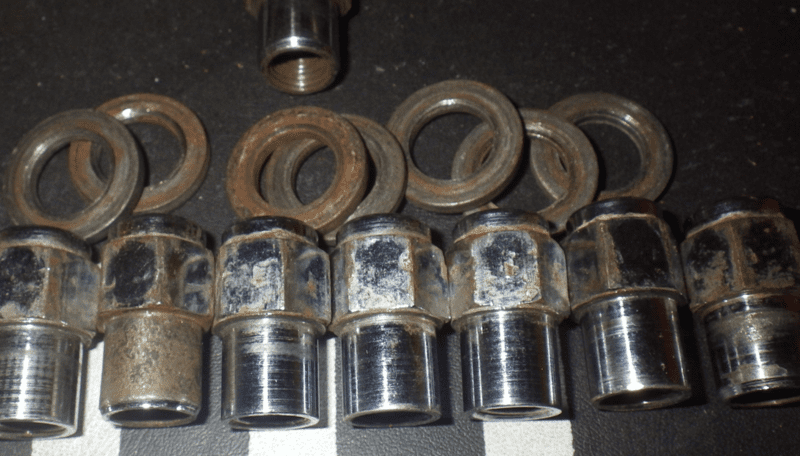

I bought 20 bbp Cragar lug nuts recently, all were garbage. Rounded edges, garbage threads, and looked poorly made too.

Returned them all.

Bought McGards, crisp edges and threads, nice washers.

Bought a deep socket to use for them and them only.

Had them off/on a few times, still look brand new.

Iirc, I posted here about them.

I bought 20 bbp Cragar lug nuts recently, all were garbage. Rounded edges, garbage threads, and looked poorly made too.

Returned them all.

Bought McGards, crisp edges and threads, nice washers.

Bought a deep socket to use for them and them only.

Had them off/on a few times, still look brand new.

Iirc, I posted here about them.

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 3,755

- Reaction score

- 2,838

4mulas

Fixem'up

As for tightening and torque references it is 55ft lbs by the manual for 7/16 inch studs and to 65 ft lbs for 1/2 inch studs. HOWEVER:

-Your wheels will likely all come loose if you torque them to 55 ft pounds. One has to keep in mind that the torque spec was for and acorn style lug nuts on a stamped steel wheel with a raised seating area where the lug nut goes. There is spring tension on them when torqued which is likely factored in.

You are torquing a flat on flat on flat. Ie: the wheel is flat on the hub, the washer is flat on the wheel, and the stud rests flat on the washer. It’s like a stack of pancakes and if you torque the to 55 I could pretty much guarantee they will come loose. Your 7/16 stud can handle 70-80 foot pounds (spec taken from many legitimate sources) with NO issue. Use 75 if you like. When installing custom wheels (especially non acorn style, most commonly referred to as Mag style nut) it is a good idea to check and recheck the torque on them often especially for the first 1000 miles at 50-100 mile intervals. They will loosen and settle until you find they will finally hold the torque value that you intended.

Another word of warning is to definitely not over torque these Cragar lug nuts (the 09004 and 09005, which as discussed are the correct ones for your application…) because the washers are thin and soft like Swiss cheese these days and they WILL bend and get sucked into the hole and wedged onto the nut. The older Cragar washers were much thicker and did not do this. I’m lucky as I have circa 1997 washers and use them instead of the newer ones. New ones are thin!. Something was lost in translation over time with new runs of manufacturing over the years. Plus they try to make everything cheaper these days.

Good luck.

PS. People will get one here and tell you both I’m nuts and you’d be nuts to listen to me if you torque to 75 ft for this application. Don’t listen to them. I know what I’m doing, have worked in the industry for 40 years and have yet to have a customer come back with broken studs or loose wheels….

-Your wheels will likely all come loose if you torque them to 55 ft pounds. One has to keep in mind that the torque spec was for and acorn style lug nuts on a stamped steel wheel with a raised seating area where the lug nut goes. There is spring tension on them when torqued which is likely factored in.

You are torquing a flat on flat on flat. Ie: the wheel is flat on the hub, the washer is flat on the wheel, and the stud rests flat on the washer. It’s like a stack of pancakes and if you torque the to 55 I could pretty much guarantee they will come loose. Your 7/16 stud can handle 70-80 foot pounds (spec taken from many legitimate sources) with NO issue. Use 75 if you like. When installing custom wheels (especially non acorn style, most commonly referred to as Mag style nut) it is a good idea to check and recheck the torque on them often especially for the first 1000 miles at 50-100 mile intervals. They will loosen and settle until you find they will finally hold the torque value that you intended.

Another word of warning is to definitely not over torque these Cragar lug nuts (the 09004 and 09005, which as discussed are the correct ones for your application…) because the washers are thin and soft like Swiss cheese these days and they WILL bend and get sucked into the hole and wedged onto the nut. The older Cragar washers were much thicker and did not do this. I’m lucky as I have circa 1997 washers and use them instead of the newer ones. New ones are thin!. Something was lost in translation over time with new runs of manufacturing over the years. Plus they try to make everything cheaper these days.

Good luck.

PS. People will get one here and tell you both I’m nuts and you’d be nuts to listen to me if you torque to 75 ft for this application. Don’t listen to them. I know what I’m doing, have worked in the industry for 40 years and have yet to have a customer come back with broken studs or loose wheels….

Daves69

Well-Known Member

IMO, the minute washer faces on these 7/16" Cragar SS lugs working against the Cragar supplied washers are too small to be reliable for holding torque. Doesn't take much to start digging into the washers. Couple that with any wear on the studs over the years you may be constantly re-torquing.

The older ones from the late '70s were no better.

The older ones from the late '70s were no better.

I think what you say here has some merit. Because of the bevels involved on the seats and the conical stock lug nuts, they will torque down and stay tight at a lighter torque spec. He still should be careful though, as not to over torque the stud itself. What I would do is look up whatever the SAE torque spec is for a 7/16 fine thread stud and use that.As for tightening and torque references it is 55ft lbs by the manual for 7/16 inch studs and to 65 ft lbs for 1/2 inch studs. HOWEVER:

-Your wheels will likely all come loose if you torque them to 55 ft pounds. One has to keep in mind that the torque spec was for and acorn style lug nuts on a stamped steel wheel with a raised seating area where the lug nut goes. There is spring tension on them when torqued which is likely factored in.

You are torquing a flat on flat on flat. Ie: the wheel is flat on the hub, the washer is flat on the wheel, and the stud rests flat on the washer. It’s like a stack of pancakes and if you torque the to 55 I could pretty much guarantee they will come loose. Your 7/16 stud can handle 70-80 foot pounds (spec taken from many legitimate sources) with NO issue. Use 75 if you like. When installing custom wheels (especially non acorn style, most commonly referred to as Mag style nut) it is a good idea to check and recheck the torque on them often especially for the first 1000 miles at 50-100 mile intervals. They will loosen and settle until you find they will finally hold the torque value that you intended.

Another word of warning is to definitely not over torque these Cragar lug nuts (the 09004 and 09005, which as discussed are the correct ones for your application…) because the washers are thin and soft like Swiss cheese these days and they WILL bend and get sucked into the hole and wedged onto the nut. The older Cragar washers were much thicker and did not do this. I’m lucky as I have circa 1997 washers and use them instead of the newer ones. New ones are thin!. Something was lost in translation over time with new runs of manufacturing over the years. Plus they try to make everything cheaper these days.

Good luck.

PS. People will get one here and tell you both I’m nuts and you’d be nuts to listen to me if you torque to 75 ft for this application. Don’t listen to them. I know what I’m doing, have worked in the industry for 40 years and have yet to have a customer come back with broken studs or loose wheels….

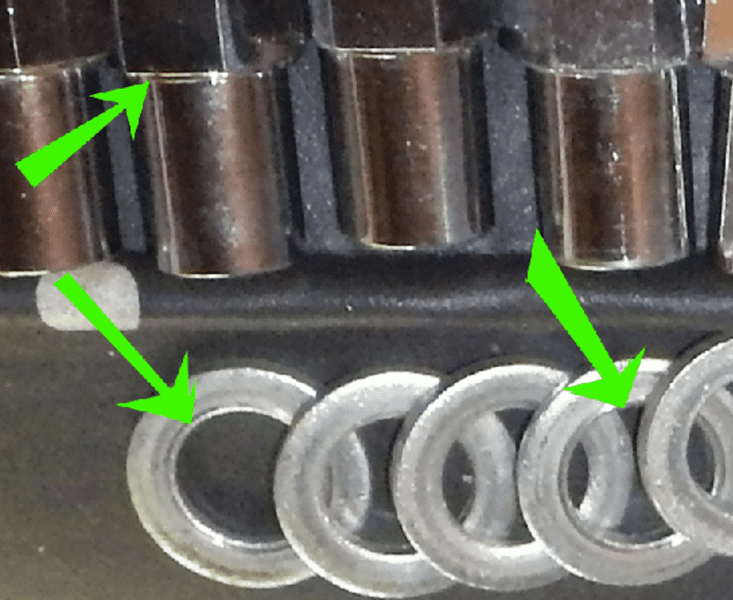

My new lug nuts from Summit came today. Three packages of LH (9400-4) and three packages of RH (9500-4). The chrome isn’t great but they appear to fit. McGard lug nuts from Jeg’s were mentioned in an earlier post, so I went to their site. I couldn’t find any McGard nuts that were 7/16” RH or LH. There was a RH thread 7/16” Dorman nut, but the shank depth was 1.69 and the nuts I received were 1.375” deep. Does anyone know of a PN from McGard or Jeg’s for something like the Summit 9400-4 or 9500-4? Pictures of the lug nuts I received today. The parts were poorly packed and all of the 9500-4 bags were open with the nuts and washers banging around loose inside the box. As noted in an earlier post, the chrome was poor, and some of the nuts had the thread double-stamped. Thanks.I bought sbp Cragar lug nuts 100 years ago, nice pieces.

I bought 20 bbp Cragar lug nuts recently, all were garbage. Rounded edges, garbage threads, and looked poorly made too.

Returned them all.

Bought McGards, crisp edges and threads, nice washers.

Bought a deep socket to use for them and them only.

Had them off/on a few times, still look brand new.

Iirc, I posted here about them.

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 3,755

- Reaction score

- 2,838

Cragar: The Wheel People, go somewhere else for lug nuts and washers.

Cragar has had different owners over the years. For a while, the chrome wasn't very good, especially around the lug nuts, where it would peel off. The last three sets I've bought (two A bodies and one B body) have had very good chrome, no peeling. Lug nuts were OK, too. Who knows about whatever is available today.

-

Similar threads

- Locked

- Replies

- 1

- Views

- 216

- Replies

- 9

- Views

- 3K

- Replies

- 15

- Views

- 7K

- Replies

- 30

- Views

- 2K