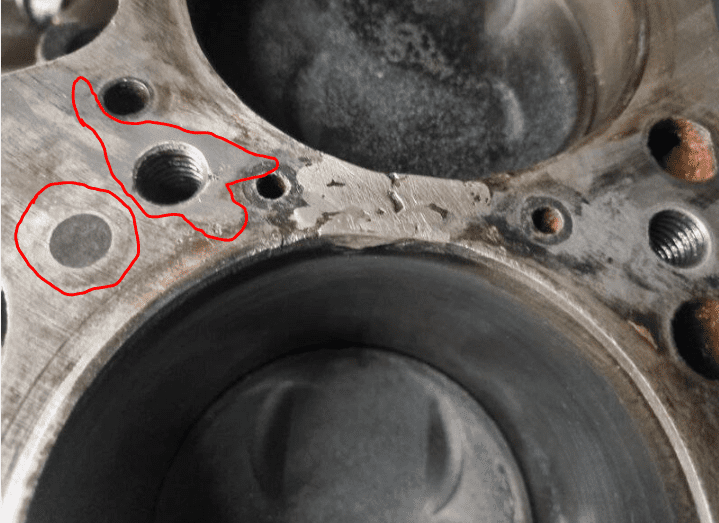

Is that silicone or sealant of some sort plugging the hole and smeared on the flame deck surface?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cylinder wall weld??

- Thread starter 1974scamp

- Start date

-

I don't disagree that it looks bad, but evidently, somehow it worked.I just say ugly as it doesn't even cover the whole flame deck surface. As horribly drawn below, I would worry about a pathway for cylinder combustion to cross talk.

View attachment 1716172326

Keep in mind, he is in another country. Someone probably did about the best they could. Not everyone has access to half million dollar machinery.Is that silicone or sealant of some sort plugging the hole and smeared on the flame deck surface?

View attachment 1716172328

Oh, I agree. Just areas of concern. I also said it can be fixed better and used - most likelyKeep in mind, he is in another country. Someone probably did about the best they could. Not everyone has access to half million dollar machinery.

So it was a sketchy fix after assembled/honed, etc It appears to have sealed and works, I would worry about that piston crown. But overall, it worked.

The whole area was covered in dirt grease and was basically all black, actually tool the head off yesterday and didnt even notice that it was repaired, only seen it today when I cleaned up the blockIs that silicone or sealant of some sort plugging the hole and smeared on the flame deck surface?

View attachment 1716172328

Someone who is really good at brazing could fill all those imperfections and then you could have the block deck skimmed. Maybe hit those bores with a hone and you'd probably make it an almost invisible repair.....but again, at what cost? Over here, that block would just get chunked in the scrap pile, but over there, they may be hard to find.

I’d deck it flat and send it. It looks like someone goobered some weld on there and did a quick file job to get it down the road.

that's a whole bunch of cam for a 318 with that compression.......and the 318 is a 1969 with the higher 9.2 compression I thought ill just clean up the bottom end, put the aluminum heads and air gap on, and a comp XE274 cam which I have laying around and see how it works.

the heads and intake will support it and you likely already have a converter and gears seeing that you were previously running a 408. but, still, that's a bunch of cam without the cubes and compression to make the magic.

Yeah, I agree. I bet it could look a whole lot better just getting decked.I’d deck it flat and send it. It looks like someone goobered some weld on there and did a quick file job to get it down the road.

i'd probably brass braze it, knock it down flat and then get a three stone to clean up the cylinder. run some forgiving headgaskets and it would probably live.

i'd just know that it's a stop gap till i find a 360.

it's a temporary fix till it isn't.

i'd just know that it's a stop gap till i find a 360.

it's a temporary fix till it isn't.

sireland67

Well-Known Member

I think it would stay together as is with iron heads, but with aluminum it may be sketchy.

The aluminum heads or going to expand more, but you would not be using the steel head gaskets......

You could just put it back together and run it.

The aluminum heads or going to expand more, but you would not be using the steel head gaskets......

You could just put it back together and run it.

mygasser

Well-Known Member

if it's only temporary you could always smear some epoxy over the weld, then fit the head gasket and head before it sets up. i had to do that once and on a diesel truck too (much, much higher compression) and it worked just fine. it was good enough that my friend never did swap it out.

neil.

neil.

MoparMike1974

Well-Known Member

That looks to have been brazed...can you confirm? I agree on brazing it up the rest of the way and decking the block .The extra compression will wake that 318 up.

Spudmaster

Well-Known Member

JB weld looking repair. Personally unless it is a “numbers matching” restoration, I would just find another 68-71 block.That looks odd and shoddy to me.

I have never seen a repair like this before from the factory.

Did it run okay and seal before you took it apart?

Or, have you never run it?

I would be looking for another block to build if it were me, after all, it's only a 318 and there are a lot of cores around for cheap.

That's my take on it FWIW...

Dale Davies

Well-Known Member

Looks like a shabby weld repair with high nickel rod. You being in Austria, blocks are not around every wrecker. VW blocks yes. I would take it to a trusted welder. They can grind it out to the parent iron metal and furnace weld with cast rod, or pre heat the area and cast iron weld. Keep some heat on and peen while cooling slowing to relieve stress.Hey all,

I just teared down my 1969 318 engine and found this (see pictures) between cylinder 4 and 6.

As I thought I removed the thin stock looking head gaskets I wondererd if this is maybe done by the factory? Anybody seen something like that before?

Actually I wanted to reuse the stock bottom end...

Thanks for the help!

View attachment 1716172195

View attachment 1716172196

View attachment 1716172197

View attachment 1716172198

The other way is to grind out the holes and weld with high nickel rod. Pre heat and peen regularly during welding to relieve stresses.

When done it should be Manaflux tested for cracking beside the weld. After that deck the block to get both square and the same height and bore the cylinders oversize for new pistons.

Now would be the time to consider what you want and possibly look to a stroker crank; 3.58" or 4".

Dale Davies

Well-Known Member

Not brazed as the brass rod is decidedly amber. That is high nickel rod, arc welded. I have seen a number of heavy duty blocks repaired this way. Always looks like stainless against the iron.That looks to have been brazed...can you confirm? I agree on brazing it up the rest of the way and decking the block .The extra compression will wake that 318 up.

Some of you guys are posting up suggestions needed for a crack. All this block needs is filler metal and can then be filed flat with a file. Ask me how I know.

Dale Davies

Well-Known Member

True that. Brazing it would do that.Some of you guys are posting up suggestions needed for a crack. All this block needs is filler metal and can then be filed flat with a file. Ask me how I know.

First I would have the block checked for cracks, especially in that area. If it is good and the divots are filled it can be filed flat or better to mill both decks to the same height.

I like the old Fram filters adverts; Pay me now or pay me later.

This is a long post so bare with me. I was racing running 10.0’s in my 440 duster. 3rd round I won but the car slowed up. No miss and oil pressure was good. I dialed up .10 for fourth round and won. Dialed up .10 again and kept doing this till the final were I lost. A quick check at home Sunday night found it was torching between 3 and 5 and ate .100 into the head and block. Monday I called and asked 7 different welders and they said for sure it couldn’t be welded together and in the car. I found a guy 20 miles from home so I towed it out. He said he could weld both and asked how I was going to machine it. I told we weld and file gears and stuff all the time in the mill so he said it would be 125.00 for both. Tuesday night it was done so I went to get it. This guys filed the head and block and I said hey what’s up. He said he couldn’t believe that could be done. He did a great job and lowered his price to 100.00. He explained hey I learned something that I can now offer. It held up great for years.

Ok guys just to keep you updated whats going on:

As when I pulled the bottom end of the 318 apart i found that one of the pistons had a massive crack in it, so i put all the 318 parts in boxes and they lay in a corner since then.

But ive found a 5.9 magnum engine out of a 1997 Dodge Ram with about 125k miles on it, was located only 1h from my house and i paid 600€ for it, sold the shorty headers that came with it for 120€ so that makes 480€ which i am quite happy about.

For that kind of money you dont even get an LA Block here in Europe (if you even find one)

As newer Jeeps and Rams were sold in Europe, Magnum engines are way better available than LAs, especially 5.2, i was lucky to find a 5.9

I bought a chinese air gap (with magnum and LA bolt pattern) on amazon which i paid 140$ for plus shipping to Europe makes about 200€.

Completed the engine with the parts from the 408, double roller timing set, milodon 8qt pan, MSD ignition, TTI headers, 750cfm Holley double pumper, but will switch to Holley Sniper EFI this year

Just these days i built a redneck running stand and the first tests were succesfull

As when I pulled the bottom end of the 318 apart i found that one of the pistons had a massive crack in it, so i put all the 318 parts in boxes and they lay in a corner since then.

But ive found a 5.9 magnum engine out of a 1997 Dodge Ram with about 125k miles on it, was located only 1h from my house and i paid 600€ for it, sold the shorty headers that came with it for 120€ so that makes 480€ which i am quite happy about.

For that kind of money you dont even get an LA Block here in Europe (if you even find one)

As newer Jeeps and Rams were sold in Europe, Magnum engines are way better available than LAs, especially 5.2, i was lucky to find a 5.9

I bought a chinese air gap (with magnum and LA bolt pattern) on amazon which i paid 140$ for plus shipping to Europe makes about 200€.

Completed the engine with the parts from the 408, double roller timing set, milodon 8qt pan, MSD ignition, TTI headers, 750cfm Holley double pumper, but will switch to Holley Sniper EFI this year

Just these days i built a redneck running stand and the first tests were succesfull

Last edited:

Brilliant!!!

Was the transmission void of fluid??

-

Similar threads

- Replies

- 7

- Views

- 393

- Replies

- 14

- Views

- 824

- Replies

- 42

- Views

- 958