I'm about to make some repairs to a 68 Dart dash wiring harness. Found some great informational threads here on the proper type connectors, so I have ordered those. Question is what type of wiring is best for replicating the OEM dash harness? I have read some threads mentioning TXL, GXL, and SXL wiring but I'm at a loss as to what would match the original, and where to buy it online.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dash Harness Repair

- Thread starter 440 Mike

- Start date

-

Mattax

Just the facts, ma'am

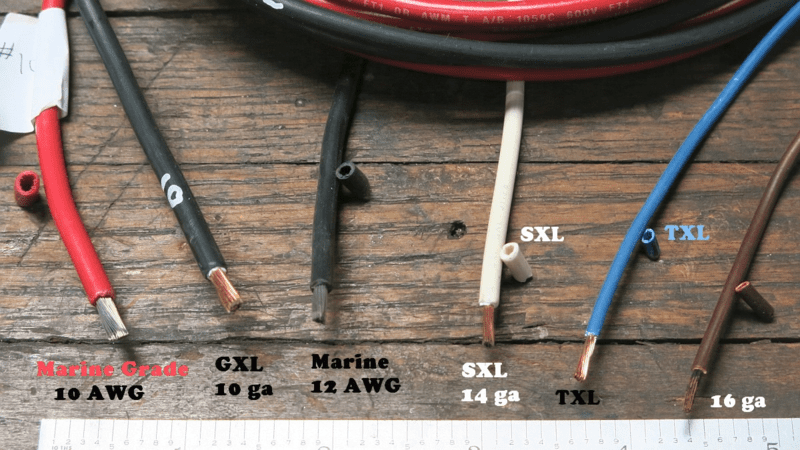

As far as I can tell, inside the car SAE "primary" or "general purpose" automotive wire is fine. Other than the heater and such, temperatures inside are normal and there is no oil or fuel. Marine wire is close to general purpose SAE although with finer wire strands which are tinned. If your in boating area, they sell it by the foot in bigger stores.

Rhode Island wire is reported to have a big selection of OEM matching wires for older and antique vehicles.

DelCity has larger and smaller (thrifty) spools in 5 or 6 colors.

www.delcity.net

Hopefully you don't have to splice in too much.

www.delcity.net

Hopefully you don't have to splice in too much.

Since its out, identify what is bad and go from there.

I bought shrink tubing from McMaster mostly because they list the properties of the different types. Flexible, oil resistant, etc.

Rhode Island wire is reported to have a big selection of OEM matching wires for older and antique vehicles.

DelCity has larger and smaller (thrifty) spools in 5 or 6 colors.

Electrical Wire & Cable | Del City

Del City offers over 1,000 electrical and automotive wire options, including 8 to 20 gauge sizes. Our selection includes primary wire, marine grade tinned wire, speaker wire, and universal wiring harnesses. Shop now for all your automotive and electrical wiring needs!

Since its out, identify what is bad and go from there.

I bought shrink tubing from McMaster mostly because they list the properties of the different types. Flexible, oil resistant, etc.

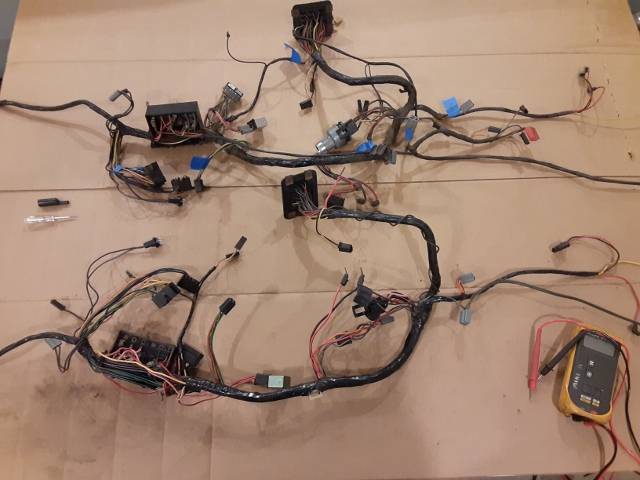

Two harnesses. The problems found so far are corroded fuse clips and the red ammeter wire was pulled out of the terminal at the bulkhead on one harness. The other harness (an air conditioning harness) looks great except for some very rusty fuse clips. I don't think they're savable.

convx4

Well-Known Member

Last winter I made new wiring for my 65 coronet.

I wanted to make some changes and up date things.

This is a list of some of the things done.

Wires colors and size (gauge) are all the same as factory.

Factory wiring diagram is mostly correct except for the changes I wanted to make. Drew new diagrams.

Engine bay wiring made to look more like the factory. Hid the head light relays under the battery.

The headlights have High and low relays that take power via a parallel tap into the Alt wire going to the battery.

Engine bay wiring is all new wire, mostly new connectors.

Alternator out put wire has 14 gauge fuse link at the starter silonoid.

A 14 gauge fusible link feeds the bulk head and inside the car.

65 Amp Alternator is now a dual field

Voltage regulator that looks original but is solid state.

The horn silonoid has a parallel tap in to the Alt 16ga wire. No fuse.

The Blue (run ) wire to the Alt field has a parallel tap to power the HEI and Coil.

Ballest restor is just for looks, solid wire buy pass

HEI mounted on a Ford E-coil, used instead of mopar ecu

Working on the under dash.

New blade style fuzes will replace the original glass fuzes.

The new fuze box will be in the glove box , when AC is installed. Under the dash until then.

Update so factor Ac can be installed.

Wiring to the blower motor for the high speed will have a relay.

The magnet clutch for the AC compressor will have a relay.

All new wires under the dash, also new plastic connectors.

Replaced the dash circuit board with a new Mr Heater board 12/22

Adding a trunk release and trunk light.

Dual Relays to the power top.

Volt gauge replace amp gauge. Wire colors need to be reversed wire conecton the same.

Bought a new rear H&H wiring harness.

Going to make a a plug in emergency. flasher that bolts in to the dash. Using a 1966 Ford bronco switch. Need plastic plugs where the steering column plugs in.

I wanted to make some changes and up date things.

This is a list of some of the things done.

Wires colors and size (gauge) are all the same as factory.

Factory wiring diagram is mostly correct except for the changes I wanted to make. Drew new diagrams.

Engine bay wiring made to look more like the factory. Hid the head light relays under the battery.

The headlights have High and low relays that take power via a parallel tap into the Alt wire going to the battery.

Engine bay wiring is all new wire, mostly new connectors.

Alternator out put wire has 14 gauge fuse link at the starter silonoid.

A 14 gauge fusible link feeds the bulk head and inside the car.

65 Amp Alternator is now a dual field

Voltage regulator that looks original but is solid state.

The horn silonoid has a parallel tap in to the Alt 16ga wire. No fuse.

The Blue (run ) wire to the Alt field has a parallel tap to power the HEI and Coil.

Ballest restor is just for looks, solid wire buy pass

HEI mounted on a Ford E-coil, used instead of mopar ecu

Working on the under dash.

New blade style fuzes will replace the original glass fuzes.

The new fuze box will be in the glove box , when AC is installed. Under the dash until then.

Update so factor Ac can be installed.

Wiring to the blower motor for the high speed will have a relay.

The magnet clutch for the AC compressor will have a relay.

All new wires under the dash, also new plastic connectors.

Replaced the dash circuit board with a new Mr Heater board 12/22

Adding a trunk release and trunk light.

Dual Relays to the power top.

Volt gauge replace amp gauge. Wire colors need to be reversed wire conecton the same.

Bought a new rear H&H wiring harness.

Going to make a a plug in emergency. flasher that bolts in to the dash. Using a 1966 Ford bronco switch. Need plastic plugs where the steering column plugs in.

Last winter I made new wiring for my 65 coronet.

I wanted to make some changes and up date things.

This is a list of some of the things done.

Wires colors and size (gauge) are all the same as factory.

Factory wiring diagram is mostly correct except for the changes I wanted to make. Drew new diagrams.

Engine bay wiring made to look more like the factory. Hid the head light relays under the battery.

The headlights have High and low relays that take power via a parallel tap into the Alt wire going to the battery.

Engine bay wiring is all new wire, mostly new connectors.

Alternator out put wire has 14 gauge fuse link at the starter silonoid.

A 14 gauge fusible link feeds the bulk head and inside the car.

65 Amp Alternator is now a dual field

Voltage regulator that looks original but is solid state.

The horn silonoid has a parallel tap in to the Alt 16ga wire. No fuse.

The Blue (run ) wire to the Alt field has a parallel tap to power the HEI and Coil.

Ballest restor is just for looks, solid wire buy pass

HEI mounted on a Ford E-coil, used instead of mopar ecu

Working on the under dash.

New blade style fuzes will replace the original glass fuzes.

The new fuze box will be in the glove box , when AC is installed. Under the dash until then.

Update so factor Ac can be installed.

Wiring to the blower motor for the high speed will have a relay.

The magnet clutch for the AC compressor will have a relay.

All new wires under the dash, also new plastic connectors.

Replaced the dash circuit board with a new Mr Heater board 12/22

Adding a trunk release and trunk light.

Dual Relays to the power top.

Volt gauge replace amp gauge. Wire colors need to be reversed wire conecton the same.

Bought a new rear H&H wiring harness.

Going to make a a plug in emergency. flasher that bolts in to the dash. Using a 1966 Ford bronco switch. Need plastic plugs where the steering column plugs in.

Lots of work!

How did you convert your ballast resistor? I want to install a hidden MSD system.

As far as I can tell, inside the car SAE "primary" or "general purpose" automotive wire is fine. Other than the heater and such, temperatures inside are normal and there is no oil or fuel. Marine wire is close to general purpose SAE although with finer wire strands which are tinned. If your in boating area, they sell it by the foot in bigger stores.

Rhode Island wire is reported to have a big selection of OEM matching wires for older and antique vehicles.

DelCity has larger and smaller (thrifty) spools in 5 or 6 colors.

Hopefully you don't have to splice in too much.

Electrical Wire & Cable | Del City

Del City offers over 1,000 electrical and automotive wire options, including 8 to 20 gauge sizes. Our selection includes primary wire, marine grade tinned wire, speaker wire, and universal wiring harnesses. Shop now for all your automotive and electrical wiring needs!www.delcity.net

Since its out, identify what is bad and go from there.

I bought shrink tubing from McMaster mostly because they list the properties of the different types. Flexible, oil resistant, etc.

I have something labeled boat wire from another project, but the insulation seems thicker than the OEM. May have trouble with the terminal crimp? I've seen some M&H harnesses that use something different than found on the OEM too.

Corrosion and rust on connectors are of concern. I chose to remove terminals from they're plastic holders and bead blast them clean and coat with dielectric grease. I also disassembled all switches and cleaned their contacts.

Mattax

Just the facts, ma'am

I've seen worse fuse box clips. If that was all I would say try to clean them up. The little brushes from electronics supplies and De-oxit work decently. IMO the weakest locations tend to be the wire crimps to the terminal.View attachment 1716165368

Two harnesses. The problems found so far are corroded fuse clips and the red ammeter wire was pulled out of the terminal at the bulkhead on one harness. The other harness (an air conditioning harness) looks great except for some very rusty fuse clips. I don't think they're savable.

This guy found some fuse box clips on ebay. I bought some from Evans and used ones from otehr FABO people.

Re: Ammeter red wire pulled out the firewall connector. Is the barb on the terminal damaged or is the plastic damaged? Definately don't want that (or any) terminal backing out when the two connectors are put together.

If you're OK with not 100% original, then one work around is to copy a '60/65amp' 'fleet' option wiring. You'll want a good grommet (and a positive locking connector if you do a connector). If you're doing that, then add a second alternator output wire as well. That's the wire that sees the highest currents.

I can't speak to hiding an MSD. It needs to have a very good and relatively short power supply circuit, and reasonable cooling.

Below is what I did on my '67 Barracuda. I used the factory grommet and single stud terminal locations. MSD joints at that terminal. MSD on/off is joined to the original run circuit that originally connected to the coil positive. Ballast resistor connects ignition run and start circuits (no change).

The R6-12ga Black is the original standard alternator output wire.

The added alternator output wire connects at the terminal stud.

As yours is a '68 it uses a different bulkhead cavity location for the A1 (battery feed) and some other circuits.

Since the battery feed was in relatively good condition, I did not run the battery feed through the grommet. If it wasn't, I would have. Make sure you put a fusible link in. Here's a diagram of one way that was done on '73 B-bodies exacept with two fusible links (one for the 6 gage wires and one for the 12 gage wires)

The assembly drawings show the same concept as a '68 A-body option. I don't know if any were actually built.

I think the terminal block should have a third wire on it as shown in the '73 diagram above, or the fusible link at the starter relay should be 16 gage (blue).

Here's the firewall grommet and wires on a Swiss export '74 A-body -uses a simialr concept although slightly different execution.

I

Last edited:

Mattax

Just the facts, ma'am

AWM on the insulation is probably marine grade.

Note that any exposed conductor, even the tinned wire, oxidizes over time. Strip and crimp it! If it shows some oxidation, cut it back if there is room or clean it before crimping. Sometimes conductor will have corrossion back under the insulation. Then its usually worth cutting out and replacing. That's why that brown wire is sitting on the bench. IIRC its from a front turn signal connector on my Jeep.

Then its usually worth cutting out and replacing. That's why that brown wire is sitting on the bench. IIRC its from a front turn signal connector on my Jeep.

Note that any exposed conductor, even the tinned wire, oxidizes over time. Strip and crimp it! If it shows some oxidation, cut it back if there is room or clean it before crimping. Sometimes conductor will have corrossion back under the insulation.

Last edited:

convx4

Well-Known Member

I removed the resistor spring wire and installed a jumper wire the same gauge as the rest of the wiring.Lots of work!

How did you convert your ballast resistor? I want to install a hidden MSD system.

I've seen worse fuse box clips. If that was all I would say try to clean them up. The little brushes from electronics supplies and De-oxit work decently. IMO the weakest locations tend to be the wire crimps to the terminal.

This guy found some fuse box clips on ebay. I bought some from Evans and used ones from otehr FABO people.

Ammeter red wire pulled out the firewall connector. Is the barb on the terminal damaged or is the plastic damaged? Definately don't want that (or any) terminal backing out when the two connectors are put together.

if your OK with not 100% original, then one work around is to copy a '60/65amp' 'fleet' option wiring. You'll want a good grommet (and a positive locking connector if you do a connector). If you're doing that, then add a second alternator output wire as well. That's the wire that sees the highest currents.

I can't speak to hiding an MSD. It needs to have a very good and relatively short power supply circuit, and reasonable cooling.

Below is what I did on my '67 Barracuda. I used the factory grommet and single stud terminal locations. MSD joints at that terminal. MSD on/off is joined to the original run circuit that originally connected to the coil positive. Ballast resistor connects ignition run and start circuits (no change).

View attachment 1716165391

The R6-12ga Black is the original standard alternator output wire.

The added alternator output wire connects at the terminal stud.

View attachment 1716165380

As yours is a '68 it uses a different bulkhead cavity location for the A1 (battery feed) and some other circuits.

Since the battery feed was in relatively good condition, I did not run the battery feed through the grommet. If it wasn't, I would have. Make sure you put a fusible link in. Here's a diagram of one way that was done on '73 B-bodies exacept with two fusible links (one for the 6 gage wires and one for the 12 gage wires)

View attachment 1716165392

The assembly drawings show the same concept as a '68 A-body option. I don't know if any were actually built.

View attachment 1716165393

I think the terminal block should have a third wire on it as shown in the '73 diagram above, or the fusible link at the starter relay should be 16 gage (blue).

Here's the firewall grommet and wires on a Swiss export '74 A-body -uses a simialr concept although slightly different execution.

View attachment 1716165398

Thanks so much for the information and great ideas! Genuinely appreciated.

The red ammeter wire was pulled out leaving the terminal behind in the bulkhead. The insulation had been stripped back (taking bets on if there was a wire nut splice repair here). No sign of heat damage at all, and was hoping that I could crimp a new terminal and reinstall. I got this harness off ebay several years ago and is in nice shape otherwise. It had a nice tachometer/console/backup light harness that I removed.

Can I soak the entire fuse block in De-Oxit? I don't think that the retaining "ears" on the fuse clips will survive a removal. I did order new clips off of ebay, but wouldn't be real comfortable crimping the double wires on them.

The alternator circuit upgrade looks like it might be something that I'll seriously consider.

I initially thought that I'd like to mount the MSD in the dash glove compartment area but the power lead length was a concern that I had.

Lots to think about!

AWM on the insulation is probably marine grade.

View attachment 1716165402

Note that any exposed conductor, even the tinned wire, oxidizes over time. Strip and crimp it! If it shows some oxidation, cut it back if there is room or clean it before crimping. Sometimes conductor will have corrossion back under the insulation.Then its usually worth cutting out and replacing. That's why that brown wire is sitting on the bench. IIRC its from a front turn signal connector on my Jeep.

View attachment 1716165405

I used TXL on an engine run stand that I built a few years back. Not happy with the thin insulation at all. Question: is the GXL closer to the OEM insulation thickness?

Mattax

Just the facts, ma'am

The GXL from Wirebarn is like a double insulation as you can see in the photo. I don't want to say if its about the same outer diameter as the automotive primary wire even though I *think* it is. I've seen that info, but don't recall where.

Here's another photo closer up.

Deoxit is relatively plastic safe. The only plastic I've seen it damage is on the plastic square fuses. Its available in different strengths. I think the general spray is 5% and also has some preservative in it. All that said, I'm not sure it will clean off heavy corrosion without some mechanical help.

The 'best' method or even just 'good' methods has been subject of debate.

Here's a couple of the threads with a variety of approaches

www.forabodiesonly.com

www.forabodiesonly.com

www.forabodiesonly.com

www.forabodiesonly.com

Some others may have experience with how far the MSD can be mounted. I've been told that inside on the firewall was occassionally done. No direct experience myself. Heat would be my concern. Others may have insight.

If the ammeter battery wire is otherwise in good shape, then splicing on to it is a reasonable approach. That will let you keep the heavy factory ring terminal. I found the most difficult terminal crimping was onto heavy wire diameters (12 gage and 10 gage) with ring terminals. Some of it had to do with the ring terminal thickness I think.

Yes lots to think about.

Here's another photo closer up.

Deoxit is relatively plastic safe. The only plastic I've seen it damage is on the plastic square fuses. Its available in different strengths. I think the general spray is 5% and also has some preservative in it. All that said, I'm not sure it will clean off heavy corrosion without some mechanical help.

The 'best' method or even just 'good' methods has been subject of debate.

Here's a couple of the threads with a variety of approaches

Cleaning bulkhead connectors

Want to clean the bulkhead connectors while motor is out I have elec spray cleaner but was wondering what ya'll use to get into the connectors and give them a good scrubbin

www.forabodiesonly.com

www.forabodiesonly.com

What do y'all use to clean the metal connectors that go into the bulkhead on either side of the fw?

FW means "firewall." I'm putting in a new bulkhead and the connectors look tarnished. Clean, replace? Tell me how you got good contact.

www.forabodiesonly.com

www.forabodiesonly.com

Some others may have experience with how far the MSD can be mounted. I've been told that inside on the firewall was occassionally done. No direct experience myself. Heat would be my concern. Others may have insight.

If the ammeter battery wire is otherwise in good shape, then splicing on to it is a reasonable approach. That will let you keep the heavy factory ring terminal. I found the most difficult terminal crimping was onto heavy wire diameters (12 gage and 10 gage) with ring terminals. Some of it had to do with the ring terminal thickness I think.

Yes lots to think about.

Last edited:

-

Similar threads

- Replies

- 3

- Views

- 675