moparstud440

Well-Known Member

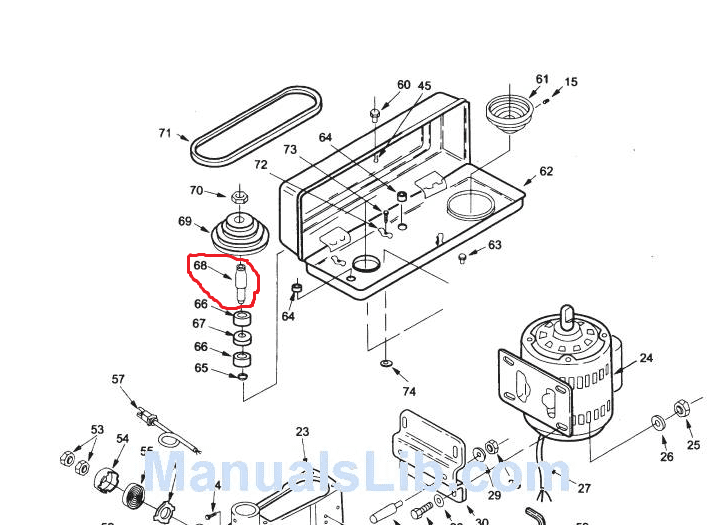

Probably a long shot but I'm trying to find a part for my broken drill press. It's a Northern Industrial drill press Part Number 155301. I need item #68 on the parts drawing. It's referred to as the insert pulley. I've tried googling and ebay and such, but without an actual part number for the part, it's hard to find anything. Didn't know if someone that maybe repairs such items or has more knowledge would be able to help me locate one or not. If not I'll just have to go buy another drill press, but was trying to fix this one if I could.