Uncle Bob

Shiny paint causes stress.

I recently had a block done including honing the lifter bores, and noticed a few lifters that are sticking a little bit when spinning the cam with no other valve train parts. I've already put the bottom end in, so honing, grinding, etc is out unless I take it all back apart so I can clean it out.

I found these burnishing balls that are supposed to fix that problem without requiring a tear down because they don't remove material, they reshape it.

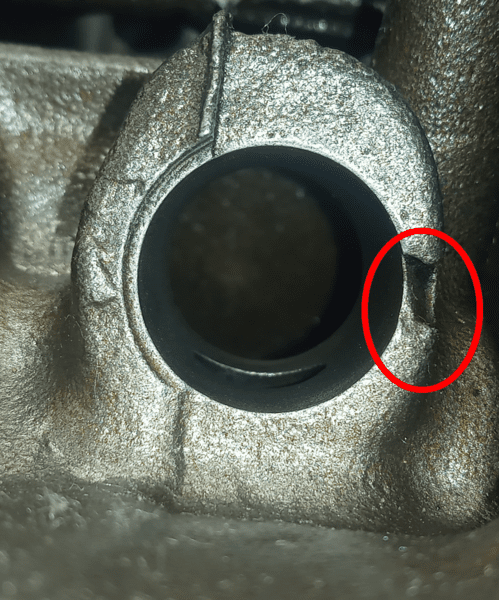

I talked to the machinist, who had no experience with them but suggested I work a lifter in the bore with the cam out because sometimes that works the "catch" out. While I was doing that, I noticed this and wondered if that is going to keep me from using the burnishing ball for fear of cracking the lifter bore.

Any advice is appreciated.

I found these burnishing balls that are supposed to fix that problem without requiring a tear down because they don't remove material, they reshape it.

I talked to the machinist, who had no experience with them but suggested I work a lifter in the bore with the cam out because sometimes that works the "catch" out. While I was doing that, I noticed this and wondered if that is going to keep me from using the burnishing ball for fear of cracking the lifter bore.

Any advice is appreciated.