moparmat2000

Well-Known Member

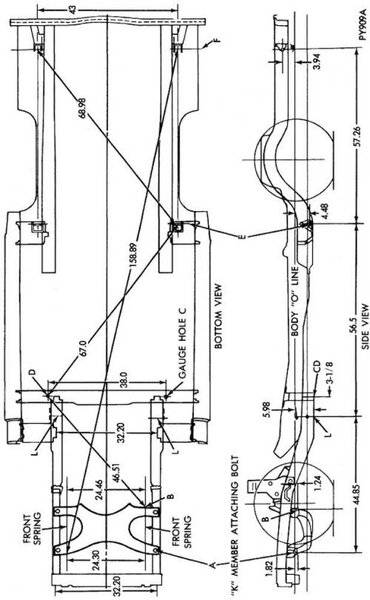

They didnt have blueprints on the line. Half those "drain holes" were for alignment pins to hold major pieces in specific dimension for assembly. Hourly wage workers were told fit this part to this part, clamp it, and weld it, send it to the next station. Heres a few reasons why I believe this to be true. 1 is the frame chart out of an FSM it has very specific holes "drain holes" and specific dimensions to those holes including hypotenuse dimensions, or cross angle alignment.

Then theres the assembly line rig pin holes. Look at the tabs on the wheel houses that fit almost a perfect 1/2" diameter rod of tool steel, and also fit at the front of the wheel house, or the 1/4" holes I used a screwdriver screwdriver shank in to align the seat back braces with the reinforcement at the package tray. All this assembly line fixturing and clamping May be the reason them K frame bolt holes line up perfectly with special shoulder bolts every time on any straight frame. This is just a few observations.

They werent ******* around with tape measures and blueprints on an assembly line. They didnt have time for it. That **** was all done at the pilot production line to work out all the bugs on the test mules including dimensional issues before the actual "real" production begins. They had definite jigs and rig pins to hold this stuff specifically at all the major stations to weld it together to maintain whatever their set tolerance was.

If my numbers are correct with just the 1968 dodge dart production being at 171,772 units being made, They were trying to pump out over 660 dodge darts a day in 1968, this doesnt include valiants, or barracudas which brings that number up quite a bit. Now Chrysler also made darts and valiants in Los Angeles as well at that time, so let's split just that 1968 dodge dart production between Hamtramck Michigan and Los Angeles California. That's still 330 dart bodies welded together per plant per 24 hour day in 1968 if working monday thru friday, 260 days a year.

Blueprints and tape measures. They didnt need it. All that crucial stuff was figured out prior to main production. "Hey Joey this is all ya gotta do for 8 hours, fit these couple parts to the fixture, clamp it, weld it in these spots, send it to the next work station, get the next pieces, and do the exact same thing over and over for an 8 hour day". I am betting this could also be part of the reason why the quality sucked and the drug use on the assembly lines was rampant back then too.

Then theres the assembly line rig pin holes. Look at the tabs on the wheel houses that fit almost a perfect 1/2" diameter rod of tool steel, and also fit at the front of the wheel house, or the 1/4" holes I used a screwdriver screwdriver shank in to align the seat back braces with the reinforcement at the package tray. All this assembly line fixturing and clamping May be the reason them K frame bolt holes line up perfectly with special shoulder bolts every time on any straight frame. This is just a few observations.

They werent ******* around with tape measures and blueprints on an assembly line. They didnt have time for it. That **** was all done at the pilot production line to work out all the bugs on the test mules including dimensional issues before the actual "real" production begins. They had definite jigs and rig pins to hold this stuff specifically at all the major stations to weld it together to maintain whatever their set tolerance was.

If my numbers are correct with just the 1968 dodge dart production being at 171,772 units being made, They were trying to pump out over 660 dodge darts a day in 1968, this doesnt include valiants, or barracudas which brings that number up quite a bit. Now Chrysler also made darts and valiants in Los Angeles as well at that time, so let's split just that 1968 dodge dart production between Hamtramck Michigan and Los Angeles California. That's still 330 dart bodies welded together per plant per 24 hour day in 1968 if working monday thru friday, 260 days a year.

Blueprints and tape measures. They didnt need it. All that crucial stuff was figured out prior to main production. "Hey Joey this is all ya gotta do for 8 hours, fit these couple parts to the fixture, clamp it, weld it in these spots, send it to the next work station, get the next pieces, and do the exact same thing over and over for an 8 hour day". I am betting this could also be part of the reason why the quality sucked and the drug use on the assembly lines was rampant back then too.

Last edited: