You might want to take a look at this thread if you have not already:

http://www.forabodiesonly.com/mopar/showthread.php?t=309417

Thanks for that. They do look good the green machine has had a lot of work. I was hoping to keep my k member and it appears the front rails have been beefed up a lot on that machine. you can see the unused holes on the right hand side through the rails for the steering box.

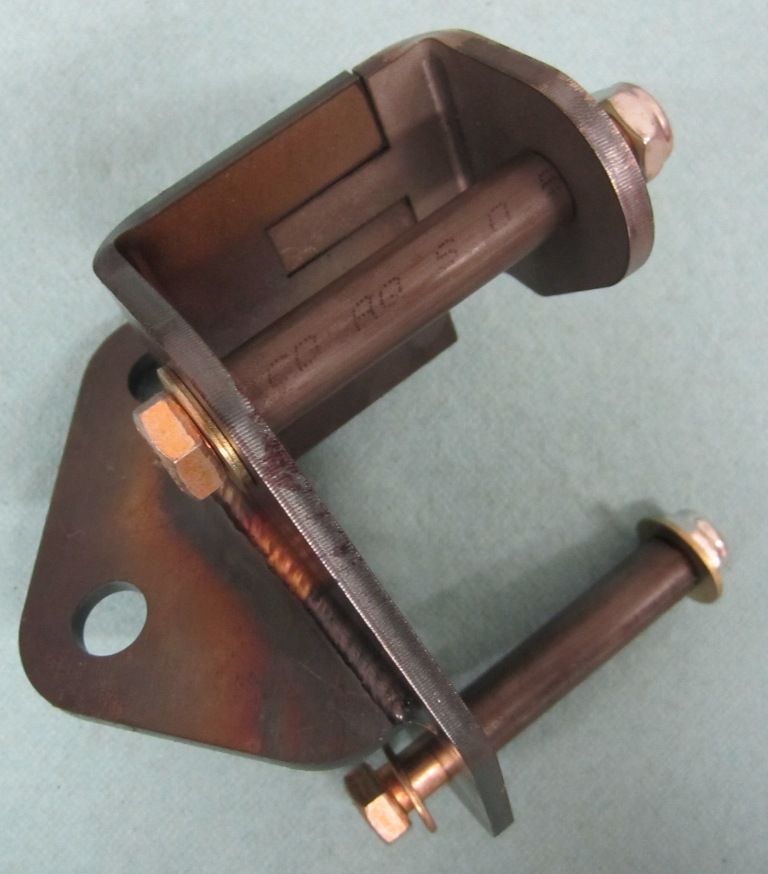

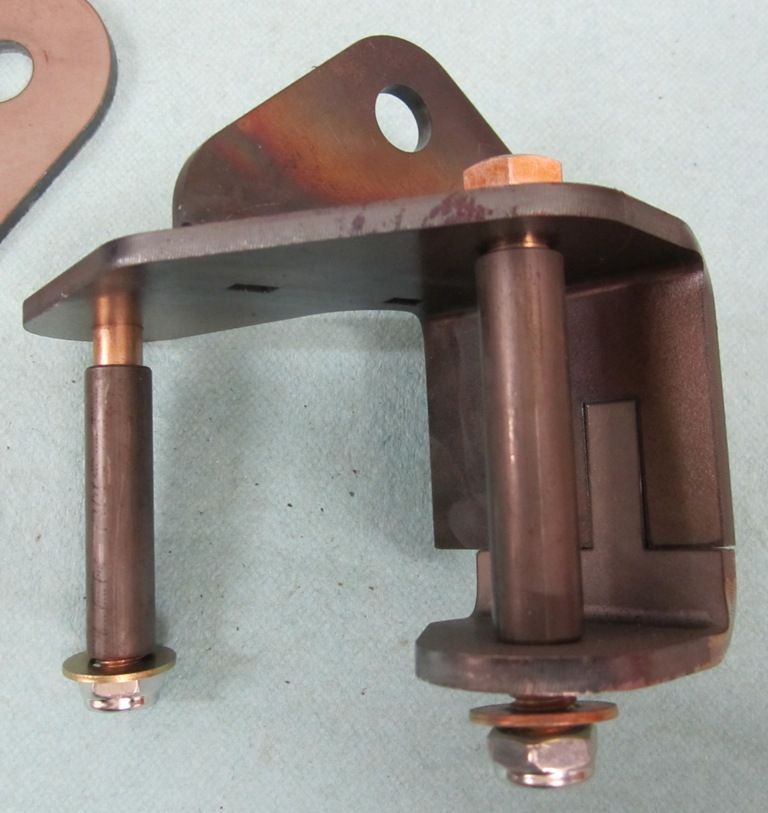

I was looking to use the existing bolts and holes for the k member to mount the hoop.

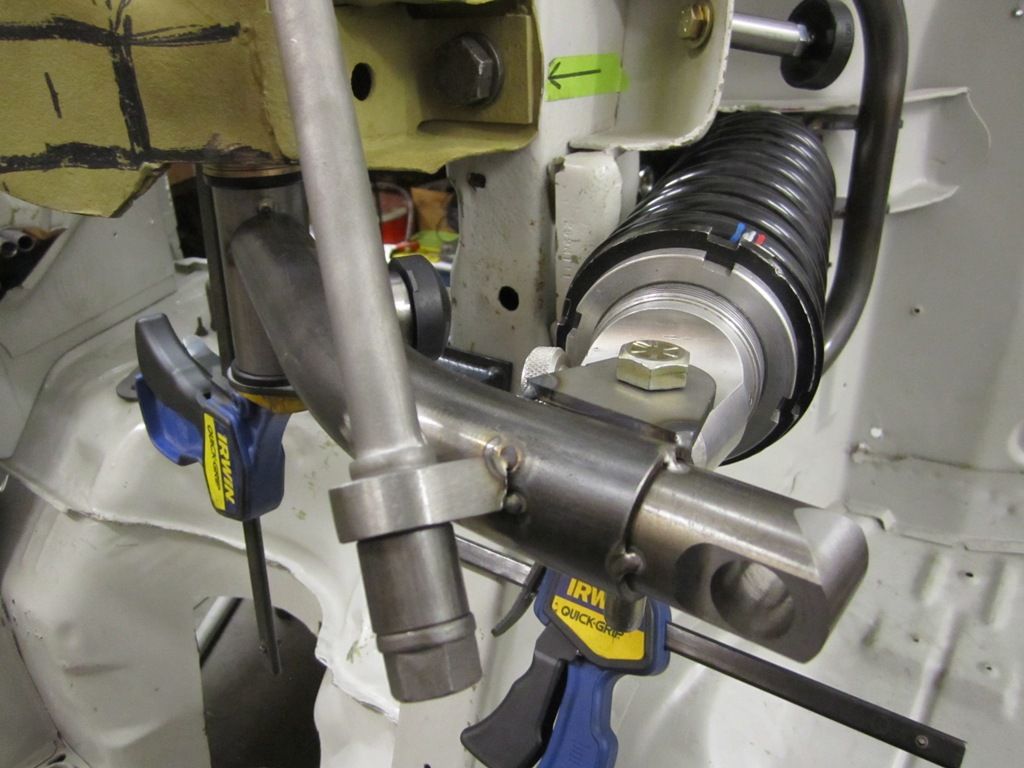

I was also looking at tying in a brace from the hoop going over the top (part of shock mount) to the top corner of the fire wall, and triangulating with a brace to the area of the hoop bottom rear. Tyre clearance becomes an issue but I think it could be done. Rather than welding to the fire wall I was looking at the brackets that are used for the front eye of the rear spring one in each corner. That would mean four holes each side of car through the fire wall and a backing plate on the inside right in front of the air boxes both sides.

I was even looking at a brace going from shock mount to shock mount going over the top rear of the motor like boomerang and the possibility to even have a bracket in the centre tying that also to the firewall. My car is the early type with the wiper motor under the dash not engine bay so the fire wall is flat and clear of crap.

My intention was to make it all removable and at this stage I'm looking at anything for ideas.

I probably shouldn't have put in my two cents worth with the comment but seeing what others do can only help us all.

Regards