I know you have all seen and replied to these threads before, but I have a little different situation. In another thread I showed my recent acquisition:

A 1998 Jeep 5.9L (360) Magnum long block. It was pulled with low compression at 149,*** miles, but I haven't pulled anything apart to see what the cylinders or pistons look like. It doesn't have an oil pump, oil pan, intake, carb, distributor, or any of the belt drive accessories.

This motor will be the eventual replacement for my Demon's slant. I'm going to convert it to an LA-style everything including a carb and LA accessory drive, so here's what I am looking for:

Daily driver motor

350-375 horsepower

375-400lbft torque

Low compression ratio for 87 octane (hopefully?)

Mild duration cam for street use

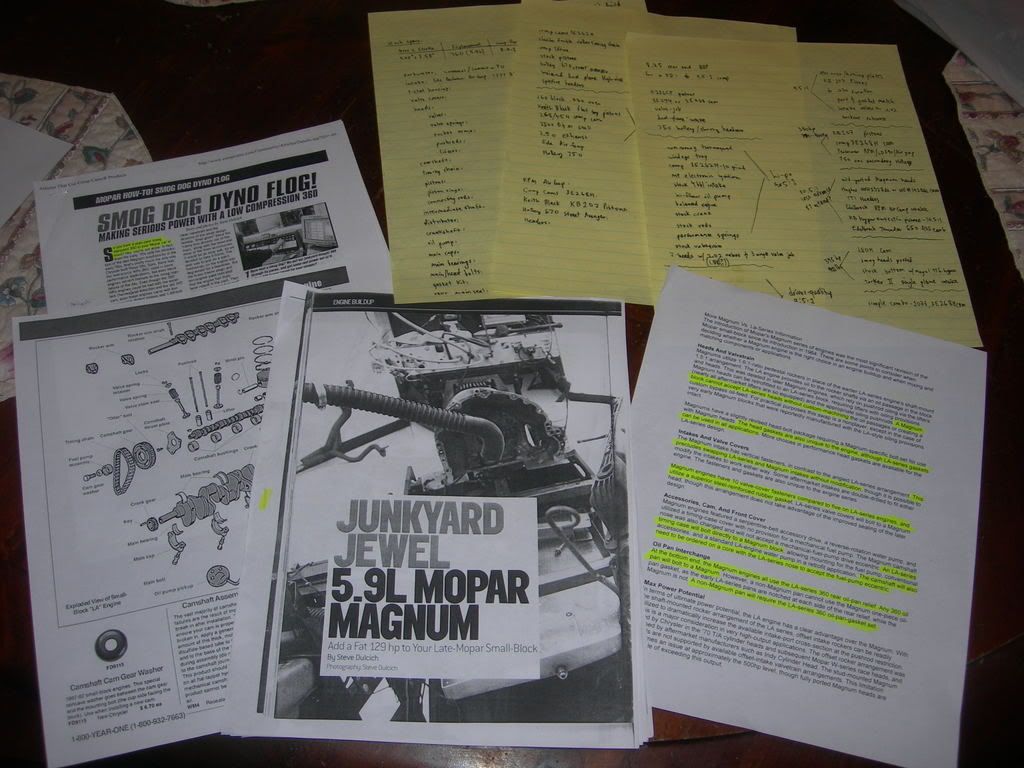

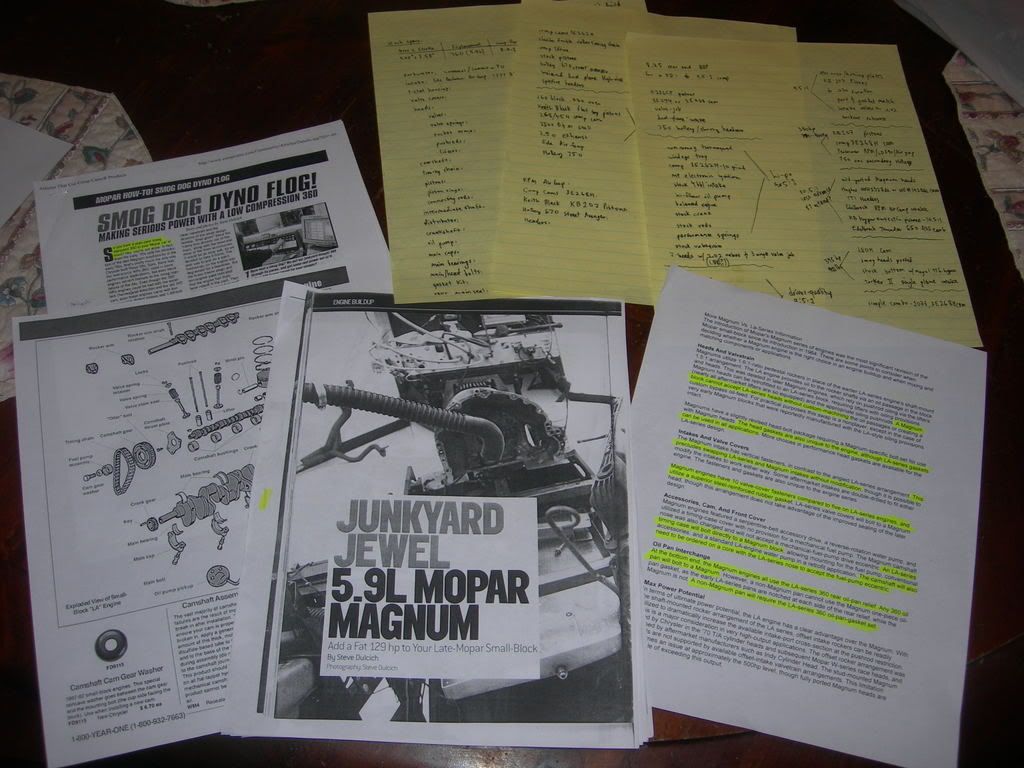

Here you can see I have done a little research:

From this research, I've come to some conclusions. I am going to run:

KB107 Hypereutectic Pistons (or stock if they're in good shape)

Federal Mogul std bore rings/gaskets (comes in a re-ring kit)

Edelbrock RPM Air Gap Intake

Holley 650 Street Avenger

MP Timing case

MP Hi-Po Oil Pump

MP Electronic Ignition Distributor

What I'm still unsure about are the heads and cam.

With the heads, I am unsure what attribute is more advantageous: the larger intake runner of the stock cast-iron magnum heads (I've read 180cc?) vs the Edelbrock RPM head's 174cc, or the lightweight aluminum construction of the RPM heads vs the stock heavy cast-iron construction.

With the cam, I have read good things about the Comp XE268H, but will that keep me streetable? The police in my town already look awry at my car, and it only has the slant in it now. More unwanted attention is very bad.

Anyway, I'll update tomorrow with a screenshot of my full parts list and see how that goes, but does this sound good right now?

Oh, last question: is it going to be at all possible to run the motor on 87 octane? Would it require too low advance? Thanks

A 1998 Jeep 5.9L (360) Magnum long block. It was pulled with low compression at 149,*** miles, but I haven't pulled anything apart to see what the cylinders or pistons look like. It doesn't have an oil pump, oil pan, intake, carb, distributor, or any of the belt drive accessories.

This motor will be the eventual replacement for my Demon's slant. I'm going to convert it to an LA-style everything including a carb and LA accessory drive, so here's what I am looking for:

Daily driver motor

350-375 horsepower

375-400lbft torque

Low compression ratio for 87 octane (hopefully?)

Mild duration cam for street use

Here you can see I have done a little research:

From this research, I've come to some conclusions. I am going to run:

KB107 Hypereutectic Pistons (or stock if they're in good shape)

Federal Mogul std bore rings/gaskets (comes in a re-ring kit)

Edelbrock RPM Air Gap Intake

Holley 650 Street Avenger

MP Timing case

MP Hi-Po Oil Pump

MP Electronic Ignition Distributor

What I'm still unsure about are the heads and cam.

With the heads, I am unsure what attribute is more advantageous: the larger intake runner of the stock cast-iron magnum heads (I've read 180cc?) vs the Edelbrock RPM head's 174cc, or the lightweight aluminum construction of the RPM heads vs the stock heavy cast-iron construction.

With the cam, I have read good things about the Comp XE268H, but will that keep me streetable? The police in my town already look awry at my car, and it only has the slant in it now. More unwanted attention is very bad.

Anyway, I'll update tomorrow with a screenshot of my full parts list and see how that goes, but does this sound good right now?

Oh, last question: is it going to be at all possible to run the motor on 87 octane? Would it require too low advance? Thanks