mopowers

Well-Known Member

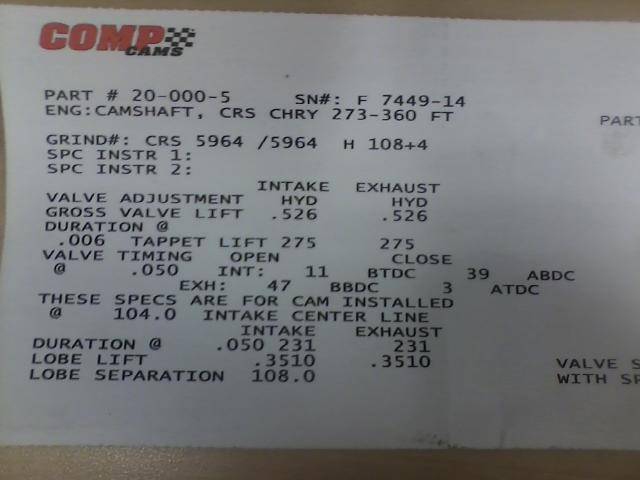

Any idea approximately how much vacuum you would expect from a 9.6:1 CR 340 with this cam?

Check your lifter preload!

Or get a second vacuum gauge; 6" is not right and would/should be giving you tuning fits. And 16* initial should be plenty. Mine runs fine down to 12* and even lower.

Yeah guys crank 'em up to 25 all the time, and if you have an automatic with a 2200plus stall, that works.

But it don't work so good in a stick-car;on account of a stick car typically idles at 6mph@750rpm, and there is no TC to absorb the power pulses, so they go straight into the rear springs.And then the car starts to do this little annoying bunny-hopping, and in a bit more time, the entire chassis gets involved.But by backing off the initial timing, the pulses are weaker, less violent. And once you get a good tune into it, you find out that just because she likes 25*, she can be happy with 14* or even less. Mine "likes" 7*@600; the bunny-hopping being all but gone. I suppose I could put some SS springs back there, but then the pulsing would go into the chassis and tires. Besides, I don't want those springs.

Yeah so,back to the top^

What PCV valve is in there?

Hang on; 750 in N/P and also 750 in gear?Thanks for the replies. The engine is already together and on the road. It runs great and seems to want quite a bit of initial timing. It's at 25* now, but seems to want more. It's got RHS heads and with 1.6 rockers, so theoretical lift is at .561". It idles great at 750, but only seems to pull 6" vacuum in gear at 750. I just thought that seemed a bit low. I don't have power brakes or anything, just wonder if 6" is all it has.

Hang on; 750 in N/P and also 750 in gear?

There's something wrong here. It can't be both, unless there's something wrong with the TC or the tach.There is usually about 50 to 150rpm drop from N/P to D/L. And A 750rpm unloaded idle, usually bangs pretty hard going into gear.

I think I have that cam in my 340 (I'll confirm later tonight) and I get 15 at 750 curb idle.

After trying most of everything already mentioned, turns out the gauge I was using was bad. I'm now at 10" vacuum at 750rpm in gear at 20* initial. Still have a bit of tuning to do on the carb, but it's getting closer. Thanks for the help guys.

post#5 ,Nov 18

IMO vacuum gauges are like hockey sticks. You can try about 5 of them, and no two work the same.

Dammed canadians !!Hockey sticks? WTH is a hockey stick? They all look the same to me.

Now, if you'd have said baseball bat...that I get. Must be the language barrier again!