racerjoe

Well-Known Member

I'm sure most people that have gotten themselves into a G3 swap without using the factory ECM end up in a situation of having to make the alternator work. I know the old school voltage regulator is supposed to work, but what about the guys who want a clean engine bay? There is certainly an aftermarket resource for a one wire battery connection alternator, but they are pricey. I have a solution to convert your G3 alternator to an internally excited, one wire (battery cable) hook up that costs $50 and about 20 minutes of your time.

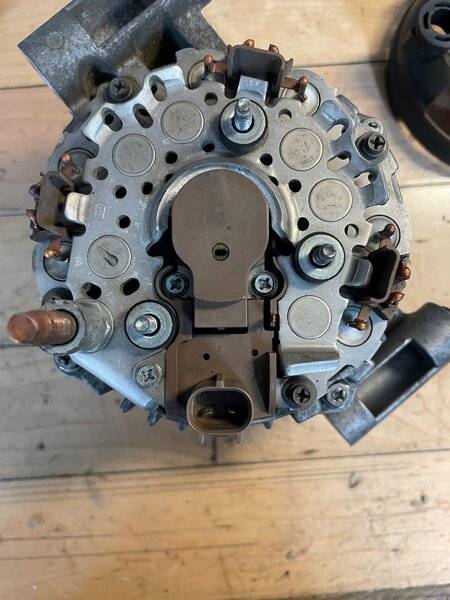

Here's how you do it. This is an 06 alternator. Once you remove the plastic back cover, this is what you will see. The brown cover over the shaft contains the brushes for the armature. The two pin connector is basically just a means for the factory voltage regulator to connect to these brushes.

Below the brush holder is removed.

Now the terminal block is removed.

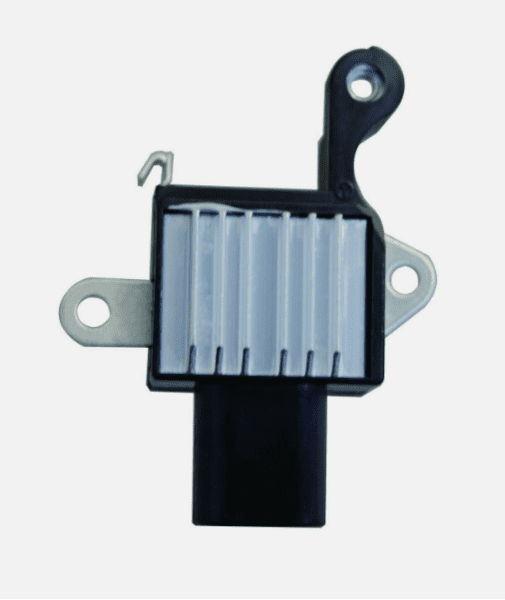

I forgot to take a picture of mine before it was installed, but this is what will be installed. It's a self excite voltage regulator for the Delphi voltage regulators. The part number is IN6324SE. You can find a few places online that sell them. Mine came from a vendor on ebay. Make sure they show "SE" in the part number because there is a IN6324 without the SE. That won't work. SE= self excite.

Note its missing a screw terminal where the original connected to the brushes. That's because this regulator requires one brush to be grounded. Also not the bent tab. That's the stator connection. It's how the VR knows when to turn on. It "reads" the frequency. Lucky for us, the diode plate already has that connection. It just wasn't being used.

So here's how you install this VR. You will need to drill and tap small hole where the red dot is located. Install the old terminal and mark the hole. I believe all the screws are M4, but I live in America and I use SAE screws...lol. Actually I had some 8-32s so that was good enough.

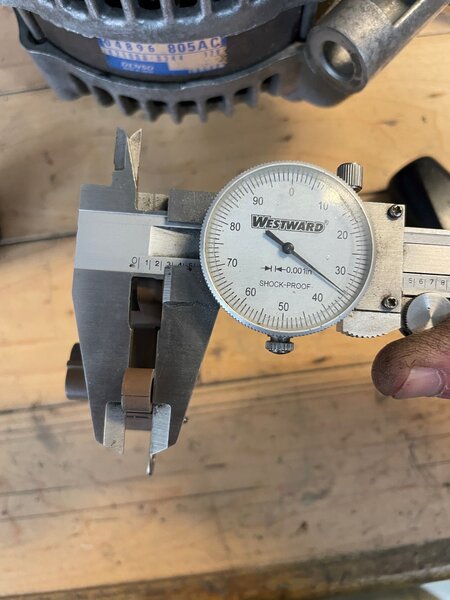

You will also need to make a small spacer to make up the difference of the old terminal used to be. I used a small piece of copper tubing for the spacer. The key is you want a good ground here. I ended up using a 1/2" long screw.

Here is installed. See that small hole in the brush holder? That's so you can stick something in there to hold the brushes back while you slide it over the end of the shaft. I just used a paperclip. Don't force it on or you will break the brushes.

Remember the stator connection I mentioned. This is it. Just solder that connection. The stud off the diode plate is copper and mine was dirty from not being used and being bare copper. Clean that off before you assemble everything so you know you will have a good solder joint.

So here I have the case of the alternator connected to battery negative and the positive on the output stud of the alternator. What you see is just battery voltage.

I spun it up with a drill and the result is obvious. It puts a noticeable load on the drill and lets off when I slow the drill down below it's operable range.

Clearly I don't have any miles on this, but it will be going on my car. I'll order a spare VR and I'll be set to convert a store replacement whenever I need to. This could be done without drilling and tapping if you just ran a ground wire to the brush holder.

The plastic back cover will need to be modified slightly for this to fit.

I hope this helps someone!

Here's how you do it. This is an 06 alternator. Once you remove the plastic back cover, this is what you will see. The brown cover over the shaft contains the brushes for the armature. The two pin connector is basically just a means for the factory voltage regulator to connect to these brushes.

Below the brush holder is removed.

Now the terminal block is removed.

I forgot to take a picture of mine before it was installed, but this is what will be installed. It's a self excite voltage regulator for the Delphi voltage regulators. The part number is IN6324SE. You can find a few places online that sell them. Mine came from a vendor on ebay. Make sure they show "SE" in the part number because there is a IN6324 without the SE. That won't work. SE= self excite.

Note its missing a screw terminal where the original connected to the brushes. That's because this regulator requires one brush to be grounded. Also not the bent tab. That's the stator connection. It's how the VR knows when to turn on. It "reads" the frequency. Lucky for us, the diode plate already has that connection. It just wasn't being used.

So here's how you install this VR. You will need to drill and tap small hole where the red dot is located. Install the old terminal and mark the hole. I believe all the screws are M4, but I live in America and I use SAE screws...lol. Actually I had some 8-32s so that was good enough.

You will also need to make a small spacer to make up the difference of the old terminal used to be. I used a small piece of copper tubing for the spacer. The key is you want a good ground here. I ended up using a 1/2" long screw.

Here is installed. See that small hole in the brush holder? That's so you can stick something in there to hold the brushes back while you slide it over the end of the shaft. I just used a paperclip. Don't force it on or you will break the brushes.

Remember the stator connection I mentioned. This is it. Just solder that connection. The stud off the diode plate is copper and mine was dirty from not being used and being bare copper. Clean that off before you assemble everything so you know you will have a good solder joint.

So here I have the case of the alternator connected to battery negative and the positive on the output stud of the alternator. What you see is just battery voltage.

I spun it up with a drill and the result is obvious. It puts a noticeable load on the drill and lets off when I slow the drill down below it's operable range.

Clearly I don't have any miles on this, but it will be going on my car. I'll order a spare VR and I'll be set to convert a store replacement whenever I need to. This could be done without drilling and tapping if you just ran a ground wire to the brush holder.

The plastic back cover will need to be modified slightly for this to fit.

I hope this helps someone!