Snake

Mopar Nut

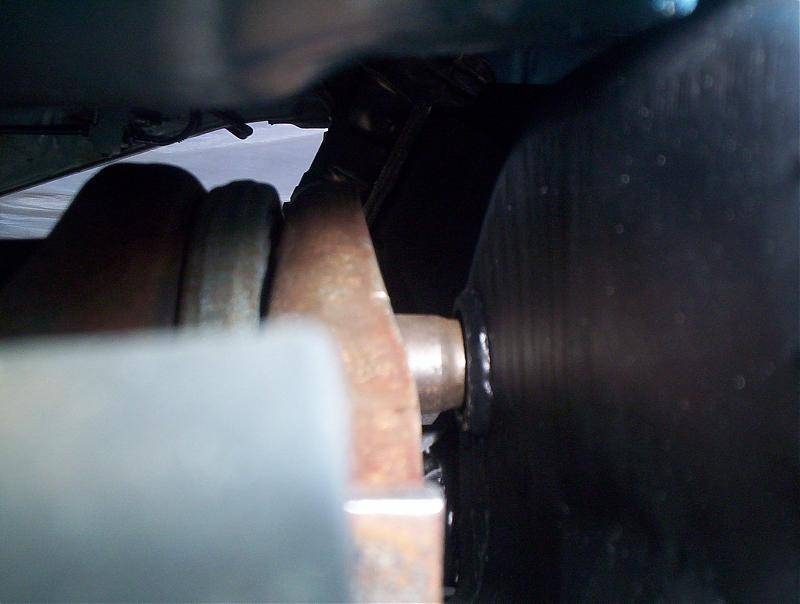

Take a look boys is this right looks like the pin is to far in.The pin is not seated into the k frame.Or am I off my rocker.

Isn't the pivot tapered right here in order not to press it in any further?

The part of the pivot is smaller that is inside the bushing right?

Correct mully

You took them to an idiot. Everybody who might rebuild their front end needs to buy a cheap 12ton press ($120 or so at Harbor Freight). The guy pressed the bushing into the LCA first and then without supporting the inner sleeve of the bushing he pressed the pin in and too far. I can show tricks on the upper bushings because it is easy to hurt the upper control arm if you aren't careful pressing the bushings in and out.