ThanksSet the multimeter to ohms. Measure the resistance from the sending unit connection to the fuel line (ground). It should be between 10 and 80 ohms. Check the oil pressure sender the same way. Just for sanity, do the temperature sender too.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I need some fuel sending unit experts please

- Thread starter bacchustn

- Start date

-

I think the connector is good. I cleaned it up and closed up the crimp to make firm contact.A number of things come to mind...

As noted... If the temp gauge works the ivr works.

If you ground the wire at the fuel sender ( very short period of time) and the fuel gauge goes up the wire is good.

BUT....

If the L shaped connector has broken internal wires they might be making connection when you test BUT not when it is connected to the sender.

Also some senders have a nut on the threaded post and that nut can interfere with the connector going on all the way and making contact.

You can connect a jumper wire from the post on the sender to the sender L shaped connector to test if it's a connector issue at the sender.

For the oil pressure gauge...

If you grounded he sender wire at the sender and the gauge did not respond then there is an open somewhere along the path.

Follow it from the engine to the circuit board and see where touching a ground wire causes gauge movement.

If no gauge movement when shorting at the gauge then the gauge is most likely bad. Sometimes you can see a bad gauge by where the needle sits with the power turned off. If it sits well below 0 or the lowest tick that is an indication.

I think my oil pressure gauge may be shot. I was able to perform a conductivity test from the sending unit to the pin in back of the dash. I did find a bare spot where the insulation had worn away which I repaired.

Here are pictures of the gauges key off and then while running

Can you tell if the gauges are dead?

They all look good from my view. doesn't mean they are though!Can you tell if the gauges are dead?

This is a new gauge but when I see OEM needles this far to the low side 9 out of 10 times the gauge has had damage

My temp gauge looked like this after my IVR failed closed. It still moved but never got above the second tick

T

Here are the readings I got on fuel with tank almost empty:10 ohm resistor between the Oil pressure gage connector and ground should bring the gage to H or approximately 80 psi

22 ohms resistance should bring the pressure gage to show middle, and anything over 75 it should show zero.

So either high resistance or no connection would keep the pressure gage from working.

PS. Like the fuel gages, replacement oil pressure senders aren't matched to the '60s gages.

Key off sending unit to ground - 62 ohms

Key on sending unit connector to ground. Video of V and Ohms ( not sure if the video will work)

iCloud Photos - Apple iCloud

View, organize, and share photos and videos with iCloud Photos on the web. Changes will sync across your devices with iCloud.

iCloud Photos - Apple iCloud

View, organize, and share photos and videos with iCloud Photos on the web. Changes will sync across your devices with iCloud.

As far as the oil pressure sender. Except for connector to gauge, which has continuity, everything reads open.

Sender to connector - open. Sender connector to ground - open. Sender to ground open. Even the body of sending unit to ground shows open.

Dartsun

Mopar Dude

Pretty helpful

Mattax

Just the facts, ma'am

Fuel sender is reading 62 ohms. A gage tester would use 73 - 74 Ohms for Empty.

So a gage connected to yours would show nearly empty.

(See Dana's graph of three sending units and you'll see they don't all read 62 ohms at the same level.)

I'm afraid you lost me after that.

You can test continuity a couple ways.

1. Power off. Meter connecting between two points in a circuit. Meter will supply a tiny amount of its own voltage to figure resistance, and display in ohms or open.

2. Power on. Test with with a meter that can read voltage between the point and ground. This only indicates power is present. It does not indicate quality of the connection.,

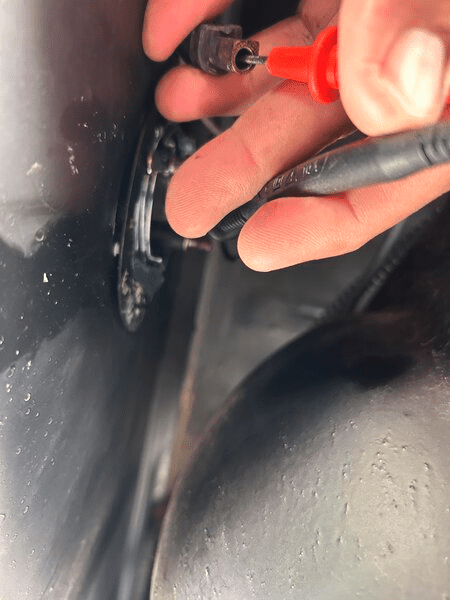

Take this image. It looks like red probe is on the wire terminal, and the black probe is on the fuel tank?

Are you trying to say the connectors are both showing the IVR is at least somewhat working?

So a gage connected to yours would show nearly empty.

(See Dana's graph of three sending units and you'll see they don't all read 62 ohms at the same level.)

I'm afraid you lost me after that.

You can test continuity a couple ways.

1. Power off. Meter connecting between two points in a circuit. Meter will supply a tiny amount of its own voltage to figure resistance, and display in ohms or open.

2. Power on. Test with with a meter that can read voltage between the point and ground. This only indicates power is present. It does not indicate quality of the connection.,

Take this image. It looks like red probe is on the wire terminal, and the black probe is on the fuel tank?

Are you trying to say the connectors are both showing the IVR is at least somewhat working?

Last edited:

I know it's corny BUT....

Watch this video

Watch this video

I know it's corny BUT....

Watch this video

Thanks, I’ve seen that one a couple times plus any other YouTube video even remotely relevant.

The pic shows red on the connector and black on the fuel sender terminal. Basically a straight through connection from gauge to sender with the multimeter in between reading voltage changes. I’m not sure if you could open the videos but I was trying to recreate the analog video with my digital meter.Fuel sender is reading 62 ohms. A gage tester would use 73 - 74 Ohms for Empty.

So a gage connected to yours would show nearly empty.

(See Dana's graph of three sending units and you'll see they don't all read 62 ohms at the same level.)

I'm afraid you lost me after that.

You can test continuity a couple ways.

1. Power off. Meter connecting between two points in a circuit. Meter will supply a tiny amount of its own voltage to figure resistance, and display in ohms or open.

2. Power on. Test with with a meter that can read voltage between the point and ground. This only indicates power is present. It does not indicate quality of the connection.,

Take this image. It looks like red probe is on the wire terminal, and the black probe is on the fuel tank?

View attachment 1716220653

Are you trying to say the connectors are both showing the IVR is at least somewhat working?

You still have the old fuel sender? Test it to make sure the resistance changes as you move the float. Then get yourself a couple long pieces of wire. Connect the first wire to the wire at the sending unit location, and the old sending unit. Connect a second wire to the battery ground and the old sending unit as a ground.

If your wires are long enough you can sit in the drivers seat with the key on and move the float on the old sending unit while you watch the gauge.

Oil pressure unit connect a long wire on the end of the wire to the unit, run the wire in the car so you can check for continuity with the wire from the gauge. This will tell you if the wire is good between the gauge and the sending unit.

If your wires are long enough you can sit in the drivers seat with the key on and move the float on the old sending unit while you watch the gauge.

Oil pressure unit connect a long wire on the end of the wire to the unit, run the wire in the car so you can check for continuity with the wire from the gauge. This will tell you if the wire is good between the gauge and the sending unit.

Mattax

Just the facts, ma'am

A voltmeter is not normally used in between the power source and the device. The device is not a good ground because it has resistance in it.The pic shows red on the connector and black on the fuel sender terminal. Basically a straight through connection from gauge to sender with the multimeter in between reading voltage changes. I’m not sure if you could open the videos but I was trying to recreate the analog video with my digital meter.

edit: it is also a high resistance device. current can not flow through a voltmeter. In other words it can not be used to make connections.

Last edited:

You can actually use the fuel sender as described to test all 3 gaugesOil pressure unit connect a long wire on the end of the wire to the unit, run the wire in the car so you can check for continuity with the wire from the gauge. This will tell you if the wire is good between the gauge and the sending unit

rebelcaptain

Well-Known Member

Did you follow the instructions when you converted to the IVR? The limiter was originally mechanically built into the fuel gauge. The reostat needs to be disabled [ie, bent out of the way of the circuit.

Dodge73Dart

1973 Dodge Dart Sport restoration

Make sure you also check the wiring running from the tank to the gauge.

Meter them checking for faults.

Meter them checking for faults.

Swinger 340

Well-Known Member

Dumb Question!!!! Do you have fuel in the tank. Reason I ask this is, the pulsing current from the dash is correct and the float unit works out of the tank (manually operating) and you say your ground is good. If you are relying on the fuel line clip strap as a ground, make sure the clips are not rusted, if so sand or replace. Also make sure the fuel line from the motor has a good ground and does not have a rubber connection be for the pump from the tank. Pump to carb is ok with a rubber line.So as near as I can tell, my system is acting like all the components work but the sending unit is not grounded. I’m getting a pulsing current (5v) from IVR through the gauge into the connector on the sending unit. Except I checked the variable resistance on the brand new sending unit before installation and it functioned. I’ve also checked that sending unit is grounded to the frame.

The gas tank is new but it could be a hole in the float or the float arm stuck down? Maybe I can remove the sending unit, ground it to frame and manually adjust the float arm. That should at least tell me if it’s the sending unit or gauge end.

There has to be a rubber hose between body fuel tube and fuel pump for flexAlso make sure the fuel line from the motor has a good ground and does not have a rubber connection be for the pump from the tank. Pump to carb is ok with a rubber line

The tube clips on the frame rail provides the grounding

Yes, there is gas in the tank. It was just below the level of the sending unit cavity. To be sure I added another 5 gals. Still showed empty. However, as I was driving off the ramps, I noticed some movement in tank level as the gas was sloshing. With probably 10 or so gals in the tank, when sloshing, I get movement up to about the level of the E line. I also ran a wire from neg terminal on battery to sending unit to insure proper ground and no change.Dumb Question!!!! Do you have fuel in the tank. Reason I ask this is, the pulsing current from the dash is correct and the float unit works out of the tank (manually operating) and you say your ground is good. If you are relying on the fuel line clip strap as a ground, make sure the clips are not rusted, if so sand or replace. Also make sure the fuel line from the motor has a good ground and does not have a rubber connection be for the pump from the tank. Pump to carb is ok with a rubber line.

Next question- is the solid state conversion to IVR give more accurate readings than a the 55 year old original one?

No.Next question- is the solid state conversion to IVR give more accurate readings than a the 55 year old original one

It actually mimics the electro mechanical units functionality.

Have you with the sender removed from the gas tank and grounded, plugged the oem sender wire into the sender and moved the sender arm through it's range.

I will try the working aftermarket sender that I replaced with this latest one. It’s out of the car so I can easily ground it and hook it up to the connection wire to see how it works. It reads 10 - 73 ohms as I run it through the full arm swing range.No.

It actually mimics the electro mechanical units functionality.

Have you with the sender removed from the gas tank and grounded, plugged the oem sender wire into the sender and moved the sender arm through it's range.

you have to be careful with the new IVR units and the new gauges. There are transistorized IVRs that are made to work with stock gauges, and identical looking IVRs that are made to use with the new replacement gauges. The two cannot be mixed. Call the company that makes the IVRs to discuss.

I checked my other sending unit today. Grounded the sending unit hooked up the connector. Went through the full range of motion on the sender arm and could get occasional readings if I wiggled the sending unit arm. Gauge works but sporadically. Decided to go fill the tank completely ( I have been sitting slightly above half a tank) to see if I could get a reading. Three gallons added, reading still on empty. 4 more gallons filled the tank, reading is now at 3/4 full. I am only reading the last 3 gallons of the tank. This is a brand new classic industries gauge that ohms out perfectly when out of the tank. Anything that might cause this other than a defective sending unit? Gauge, wiring, ground IVR?I will try the working aftermarket sender that I replaced with this latest one. It’s out of the car so I can easily ground it and hook it up to the connection wire to see how it works. It reads 10 - 73 ohms as I run it through the full arm swing range.

I’ve got a new RTE IVR3. Any reason not to install? I’m pulling the dash to install a working oil pressure gauge.

-

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 8

- Views

- 1K

- Replies

- 6

- Views

- 1K

- Replies

- 2

- Views

- 739

- Replies

- 5

- Views

- 1K