mopowers

Well-Known Member

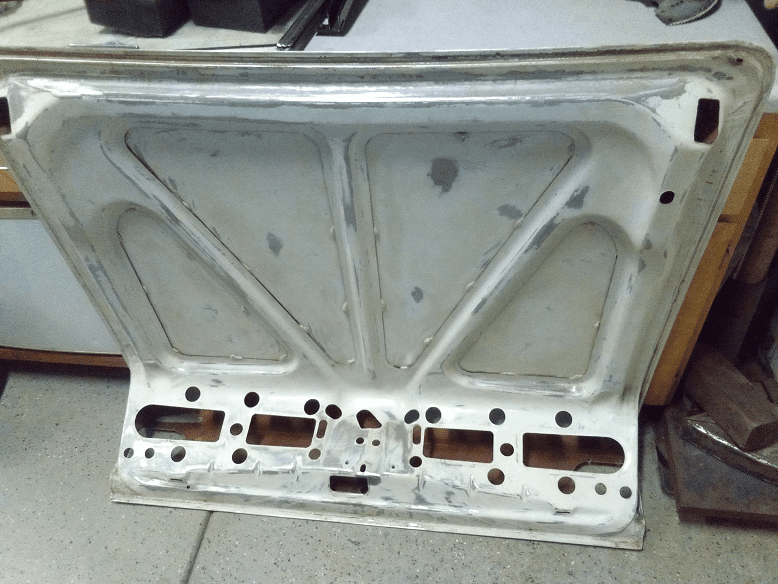

At what point would you guys consider separating a decklid to treat rust??

I'm trying to decide whether that's necessary for the decklid on my '66 Dart build. All of the exposed metal is solid, but as you can see in the photos, the inner structure/metal is rusty - to the point where a couple pinholes are poking through. I'll obviously be repairing the pinholes with fresh 18g metal, but I'm curious what you guys would do.

The other option I'm weighing is treating it with phosphoric acid the best I can. I'm kind of leaning this way because the thought of trying to get the trunk panel gap as good as it is now once it's split sounds like a total pain in the *** and the car is just a hotrod - definitely not shooting for perfection here. What would you do???

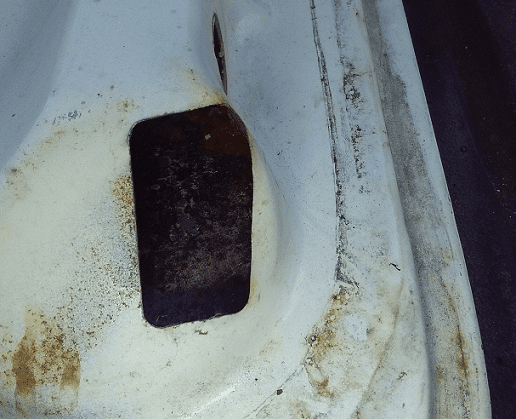

Here's a spot where I experimented with some acid rust treatment (below). It seems to do a decent job, but I doubt I'll be able to reach every spot that needs it.

I'm trying to decide whether that's necessary for the decklid on my '66 Dart build. All of the exposed metal is solid, but as you can see in the photos, the inner structure/metal is rusty - to the point where a couple pinholes are poking through. I'll obviously be repairing the pinholes with fresh 18g metal, but I'm curious what you guys would do.

The other option I'm weighing is treating it with phosphoric acid the best I can. I'm kind of leaning this way because the thought of trying to get the trunk panel gap as good as it is now once it's split sounds like a total pain in the *** and the car is just a hotrod - definitely not shooting for perfection here. What would you do???

Here's a spot where I experimented with some acid rust treatment (below). It seems to do a decent job, but I doubt I'll be able to reach every spot that needs it.

Last edited: