So top hole has an existing bolt......which I believe is going to be long enough to run all the way thru to the engine block.......about 5 inches or so thru the water pump.

some of the water pump bolts go into the water jacket (and need thread sealer) of the engine AND if you use a bolt that is too long can crack the cylinder wall.

Bottom hole and bolt should be the same, except it isn't. Hole bottoms out about 1/2" in. My guess is there is either a stud in there, or a bolt that has been twisted off.

I agree that sounds like it. get a coat hanger sized wire and see how deep it goes ( this can be used on ALL bolts) then accounting for bracket thickness be sure the bolts are a 1/4" shorter then the max depth of the wire

Either way, there is no way to bolt the bracket up as is.......so looks like I get to pull the water pump to find out. When I loosened the top bolt, antifreeze started leaking out, so to even pull that, looks like I need to drain radiator. All this just to swap out the alternator to what should have been there in the first place.

Yep its a water pump and you will need to drain the coolant no matter what you do. as stated earlier some of the bolts go into the water jacket

Which bolts reach water jacket on 340

from post #3 thanks TMM

Measure Measure Measure the max depth and subtract 1/4" (the numbers here might be right for the particular engine bracket combo it has yours might be different)

Did I mention Measure!

So questions are..........am I right to think there are two 5 inch or so bolts needed to bolt bracket base to the water pump?

Not knowing which bracket you are using AND the need to use the correct bracket so the ALT will align with the other pulleys you might be better off to make something yourself

If I pull the water pump, is there a rubber or other gasket that has to be replaced?

There is a water pump gasket, most likely fiber of some type and it only goes on one way to the pump but can be applied either way on the timing cover so be sure its on correctly

Also, when ordering bracket, choices were cast iron (pre 70's) water pump or aluminum (1970's and later). I went with aluminum.........does that also look right?

Your water pump looks like a cast iron water pump, can you stick a magnet to it?

BUT it might be an industrial water pump vs and automotive pump (It looks odd from the angle the photo was taken)

There are differences between the heights of mounting bosses for Cast Iron vs Aluminum

Note the inlet on the Cast Iron is on the drivers side and the Aluminum is on the passenger side

Cast iron water pump

Aluminum water pump

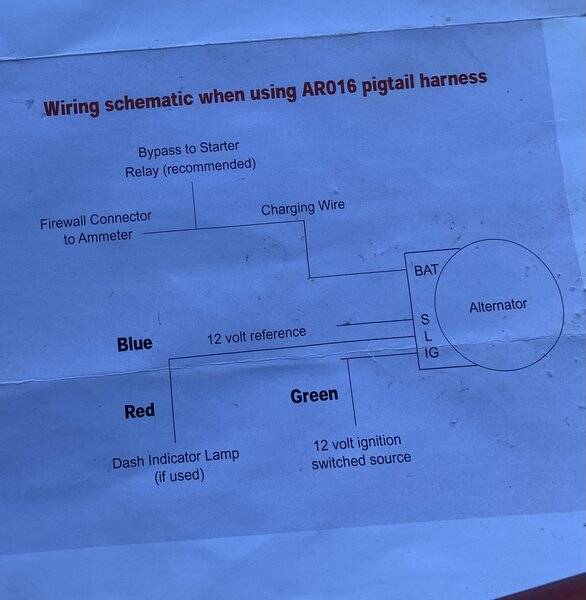

This is very typical of the Alternator mounting bracket and adjuster arm on SB mopars

The bolts are longer or shorter for the CI vs AL pump and there are spaces that might be longer or shorter

I believe this is 70 and newer

And this is 69 and older

sorry iphone camera truely sucks in low light

Your phone is fine, its the light I circled blinding your camera so it reduces the aperture and gets a bad photo