Has anyone ever taken a ported head that has been flowed and simply changed it from 11/32 valves to 5/16 valves. Then reflowed the same port. Same type of valve job, same valve manufacturer

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just thinking outside the box today

- Thread starter pittsburghracer

- Start date

-

I'm almost positive that if someone here hasn't tried it, that you well soon enough and tell us of the results.

It’s just something I’m kicking around now that I can do it. The heads on my duster have the heads in that I bought around 2005 used and damaged. I ported them in 2008 and they have been freshened over and over again and are on their at least 3rd engine of mine. I semi fixed a smoking problem last year (intake gasket) but if I get this set of heads I’m working on done I would like to update the porting on them and if the guides are bad kicking around installing 5/16 valve liners. Just winter thinking right now but I was curious if it’s worthwhile.

.031 smaller stem in the most important area of the head. I bet it is worth something since you're adding CSA

I would think so too. Taking examples from newer technology magnum heads and LS type head’s running 5/16 (8 mm) sized valves.

I have looked at that stuff too, since there's more LS valve sizes available build my Dakota r/t heads with those. Magnum ports could use a tapered stemI would think so too. Taking examples from newer technology magnum heads and LS type head’s running 5/16 (8 mm) sized valves.

Newbomb Turk

Well-Known Member

Has anyone ever taken a ported head that has been flowed and simply changed it from 11/32 valves to 5/16 valves. Then reflowed the same port. Same type of valve job, same valve manufacturer

I have. The flow increase was small. I think it was 5 CFM or something.

I didn’t care about the flow. The valve weight was what I cared about. I forget what the weight savings was, but at that point using 5/16 stems was cheaper than Ti valves, which I eventually went to.

Im not sure I can prove it, but any time you put a round section in an air column it makes turbulence and IMO that’s never good, but what we get to live with.

I can post weights today of the 2 different stem valves, all other dimensions sameI have. The flow increase was small. I think it was 5 CFM or something.

I didn’t care about the flow. The valve weight was what I cared about. I forget what the weight savings was, but at that point using 5/16 stems was cheaper than Ti valves, which I eventually went to.

Im not sure I can prove it, but any time you put a round section in an air column it makes turbulence and IMO that’s never good, but what we get to live with.

I have. The flow increase was small. I think it was 5 CFM or something.

I didn’t care about the flow. The valve weight was what I cared about. I forget what the weight savings was, but at that point using 5/16 stems was cheaper than Ti valves, which I eventually went to.

Im not sure I can prove it, but any time you put a round section in an air column it makes turbulence and IMO that’s never good, but what we get to live with.

The set of Edelbrock heads I’m working on now are on standby for PAK springs. They have him going with a way smaller diameter spring on his .700

Cam combo. Again for weight.

As i read this post, i see the merit in going to the 8mm valve stems. PR, IMHO your own eval of this move is important because you would have control over the whole test, as well as rhe ability to try any tweaks that may give added results. So many questions come to mind . Maybe extra flow from 8mm stems might only gain 5 to 7 hp?

But a couple hundred more productive rpm up top might allow an average of horsepower to go up even more. I would assume this might be more true on a motor with lots of flow available per cubic inch, versus a head limited combo?

But a couple hundred more productive rpm up top might allow an average of horsepower to go up even more. I would assume this might be more true on a motor with lots of flow available per cubic inch, versus a head limited combo?

My plan for the MGB head I'm working on, 200SX valve the size of the "Big Valve" mid-'70's 1.8L, 7mm stem vs the 11/32" monsters on the tiny stockers. Plus room abounds to move the intake over away from the chamber/cyl., tool-steel LS retainer for comparo to MG, another~16grams(>60%) gone.

@MOPAROFFICIAL is a big proponent of smaller valve stems. Maybe he'll chime in too.

And the LS folks are going to 7mm stem stuff on the really hot stuff, the guy I'm doing the MGB unit on was a little nervous about the idea at 1st, lol!! I told him, uhh if a 2nd Gen Hemi can crank 8K on 5/16 stems w/a 2.30" head hangin on the end, poppin' at the will of a solid roller,......your little MG will be fine.I would think so too. Taking examples from newer technology magnum heads and LS type head’s running 5/16 (8 mm) sized valves.

I once flow tested an 11/32 valve in a 3/8 guide iron head by carefully cutting and wrapping 0.010"-0.012" plastic shim stock around the stem. It was a little crude, but it worked good enough for a flow test. I have the flow results, but they are meaningless because it was not a true A to B comparison test.

I once flow tested an 11/32 valve in a 3/8 guide iron head by carefully cutting and wrapping 0.010"-0.012" plastic shim stock around the stem. It was a little crude, but it worked good enough for a flow test. I have the flow results, but they are meaningless because it was not a true A to B comparison test.

I’d be curious to see your results.

Too many variables were changed at one time (back cut angles and clay in the port), so the results mean nothing. I'll try to repeat the test tonight and change nothing but the valve. I have two very similar single angle valves I can try. You've got my curiosity up as well.

The set of Edelbrock heads I’m working on now are on standby for PAK springs. They have him going with a way smaller diameter spring on his .700

Cam combo. Again for weight.

Springs and retainers finally came this week. I guess I better get busy.

MOPAROFFICIAL

Oogliboogli

If he's comparing a nail head to a tulip... it is not a good comparison. The stem will not be the reason for this massive increase you see as much as that tulip valve Under head eating up bowl volumeI’d be curious to see your results.

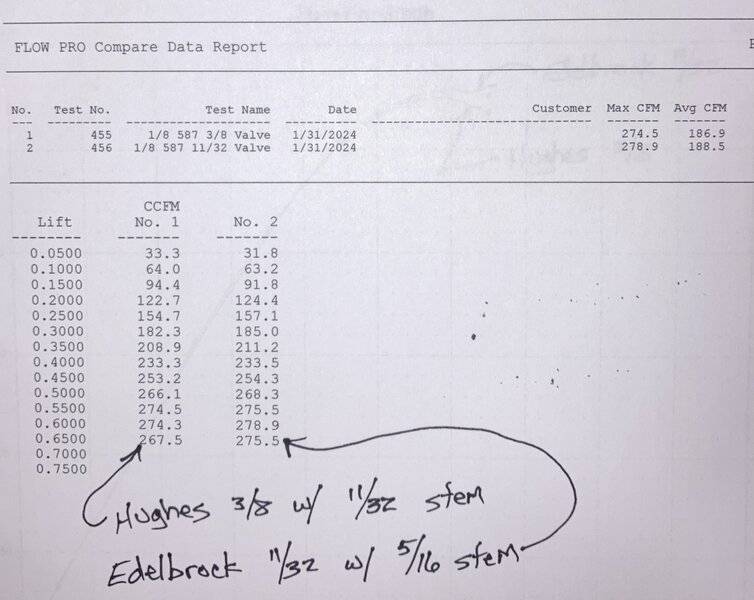

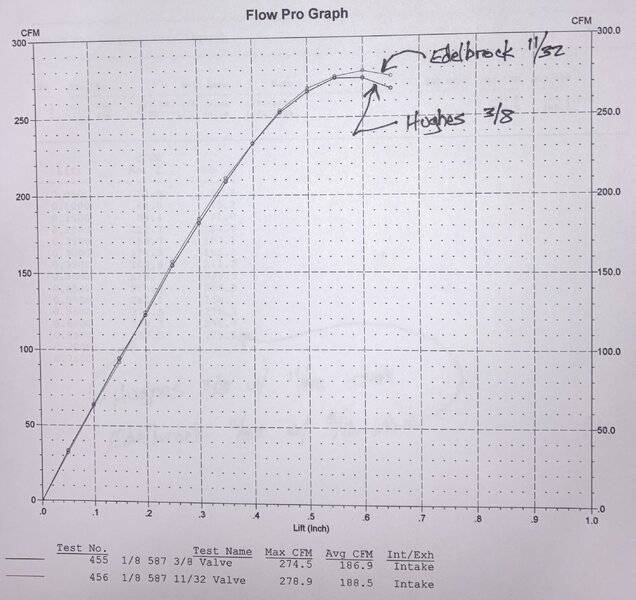

Here's the results of the valve stem diameter test. Tests were run back to back on a ported SBM steel 587 head from a 1973 360 motor. Valve diameter is 2.02. Single 45 degree angle on both valves. No backcut. First valve was a Hughes 3/8 valve with an 11/32 reduced stem. Second valve was an Edelbrock 11/32 with a 5/16 reduced stem. Both valves are nail head and appear to be similarly shaped.

Newbomb Turk

Well-Known Member

Here's the results of the valve stem diameter test. Tests were run back to back on a ported SBM steel 587 head from a 1973 360 motor. Valve diameter is 2.02. Single 45 degree angle on both valves. No backcut. First valve was a Hughes 3/8 valve with an 11/32 reduced stem. Second valve was an Edelbrock 11/32 with a 5/16 reduced stem. Both valves are nail head and appear to be similarly shaped.

View attachment 1716200257

View attachment 1716200258

View attachment 1716200259

That’s pretty close to what I remember seeing.

If you have a gram scale would you mind dropping both valves on there to check the weights?

MOPAROFFICIAL

Oogliboogli

What degree underhead on each?

12?

12?

MOPAROFFICIAL

Oogliboogli

Most 2.02 11/32 are around 120 grams

Newbomb Turk

Well-Known Member

Most 2.02 11/32 are around 120 grams

That’s sounds about right. What I can’t remember is what the 3/8 stem stuff weighs. I’d run out to the shop and do it but I doubt I have a 3/8 stem valve out there.

-