Thank-You. It's all mig welded. I wanted to support it, but didn't want to box it in totally for fear of rotting from the inside out so the gusset I made included an access hole without compromising strength. Man, some of the welds on this thing were really bad.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

K-FRAME STITCH WELDING......THOUGHTS?

- Thread starter CFD244

- Start date

-

Good work!

Some of the stock welds on these cars were hilariously bad. Some were fine, just depended on who was doing the welding or who was doing the quality control. The steering box mount on the '74 V8 K in my Duster was cracked in multiple places and almost entirely free because of cracks on the bottom of the weld to the K. The whole steering box would move back and forth when the wheel was turned. Your gussets look good, certainly a big improvement over the original set up.

Some of the stock welds on these cars were hilariously bad. Some were fine, just depended on who was doing the welding or who was doing the quality control. The steering box mount on the '74 V8 K in my Duster was cracked in multiple places and almost entirely free because of cracks on the bottom of the weld to the K. The whole steering box would move back and forth when the wheel was turned. Your gussets look good, certainly a big improvement over the original set up.

Dave_J

Well-Known Member

This is a 1967 Dart 270 \6.First picture was stock and the steering box would move around a lot. Also 1 weld nut was loose.

Last edited:

Dave_J

Well-Known Member

More including Idler arm bracket that was soo loose it wobbled before.

Dave_J

Well-Known Member

After all welding and adding gussits, with a Firm Feel Police box and long pitman arm with matching idler arm this Dart feels better than a Rack & Pinion.

Very nice....I ended up doing some gussit work, but not as extensive as yours. I was a little leary sealing everything up. I had a trailer made of tubing that rotted from the inside out, so I am a little gun shy. Thanks for the pics.After all welding and adding gussits, with a Firm Feel Police box and long pitman arm with matching idler arm this Dart feels better than a Rack & Pinion.

View attachment 1715829156 View attachment 1715829157 View attachment 1715829158 View attachment 1715829159

Dave_J

Well-Known Member

Thanks, but I did not seal the corners where it was lower than the main parts. I allowed it 'Weep" room.

Dave_J

Well-Known Member

I used a Lincoln SP155 220 volt, 0.030" wire and 75/25 Argone/co2. I also used Mapp Gas torch to pre heat any thicker steel so it had excellent penetration. All added steel was 11 Gauge. Easy to bend with heat. All bends were done with a bench vice and a crescent wrench and Mapp Gas as heat. Totally backyard.

Dave_J

Well-Known Member

Now, weld up the lower control arms and add a plate to the under part.

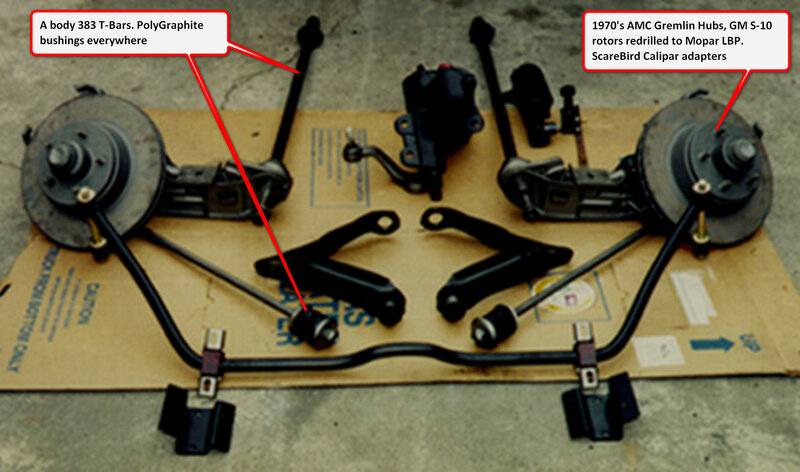

The Stock Dart 270's \6 SBP spindles were used but added Gremlin Drum brake hubs without the drums and redrilled Chevy S-10 rotors to fit the LBP. At the time the only Caliper adapters for disc brake conversion a was "ScareBird"

The Stock Dart 270's \6 SBP spindles were used but added Gremlin Drum brake hubs without the drums and redrilled Chevy S-10 rotors to fit the LBP. At the time the only Caliper adapters for disc brake conversion a was "ScareBird"

Last edited:

Sweet....Been there, done that, bought the tee shirt! My front suspension is the original K/H front end. Did all my work with 1/8 plate, and made my own lower gusset plates for the lowers. How do you like the poly? I bought all poly stuff, then chickened out and went OEM rubber except for the link ends and sway bar bushings.Now, weld up the lower control arms and add a plate to the under part.

View attachment 1715829174

The Stock Dart 270's \6 SBP spindles were used but added Gremlin Drum brake hubs without the drums and redrilled Chevy S-10 rotors to fit the LBP. At the time the only Caliper adapters for disc brake conversion a was "ScareBird"

View attachment 1715829175

Dave_J

Well-Known Member

I did plain Polyurethane bushings on my 65 Barracuda and its "SQUEEEEEEKY". My Barracuda has 68 B body disc front end with LBP.

On this Dart 270, we used Graphite impregnated poly's and they do not squeak.

On this Dart 270, we used Graphite impregnated poly's and they do not squeak.

Swinger 340

Well-Known Member

Great idea, check the welds!!!! Steering gear box mounts seems to be the weakest point in the steering. The radial tires of today seems to be the main problem of the gear box mount cracking. Larger tires in the front also cause an issue. These cars of the day were not designed for these upgrades. Had a B-300 Van that had these same problems after I installed M50's on the front. Drag racers only, should not have this problem, with the small tires in the front, but I careful look should be done at the rest of the K member, especially at the motor mounts and lower control arms. Note: Many aftermarket apps. use a 6 cly. K member which may not be as durable as a HP V-8.

Great idea, check the welds!!!! Steering gear box mounts seems to be the weakest point in the steering. The radial tires of today seems to be the main problem of the gear box mount cracking. Larger tires in the front also cause an issue. These cars of the day were not designed for these upgrades. Had a B-300 Van that had these same problems after I installed M50's on the front. Drag racers only, should not have this problem, with the small tires in the front, but I careful look should be done at the rest of the K member, especially at the motor mounts and lower control arms. Note: Many aftermarket apps. use a 6 cly. K member which may not be as durable as a HP V-8.

Honestly, the steering box welds can be a problem even with bias ply tires. Just depends on the K member, some received some really poor welds. Adding radials of any kind though can definitely increase the stress on those welds.

As for the /6 K vs the V8 K, I’ve seen absolutely nothing from a structural standpoint to suggest that the /6 K’s would be weaker. Their main construction is identical. The engine mount layout is the only difference, but the impact of that on the overall strength of the K is really minor. Like probably not worth thinking about minor. It’s only one example, but of the two 1974 K’s I have the V8 K was the one with the cracked steering mount, the /6 K I pulled to swap to a V8 was fine.

Last edited:

-

Similar threads

- Replies

- 71

- Views

- 4K

- Replies

- 3

- Views

- 526

- Replies

- 14

- Views

- 866