Tylan

Well-Known Member

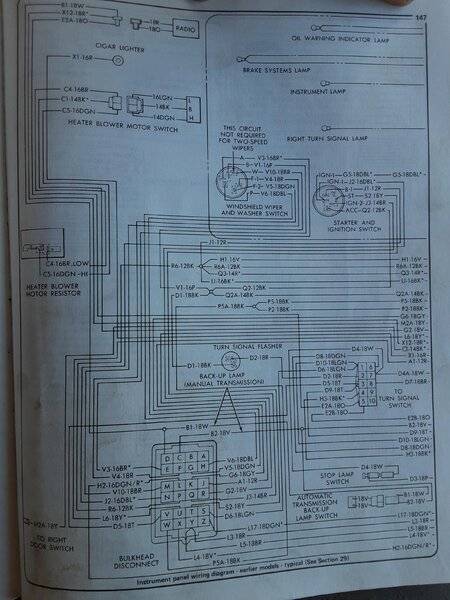

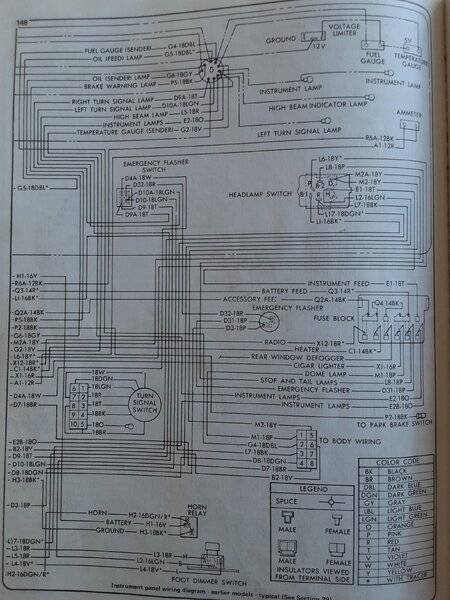

This may be a little large for one post but, I recently got a '74 Plymouth Duster that starts, runs, and moves great; however, none of the dash lights (instrument panel, gear indicator, climate control, radio), turn signals, or brake lights work properly. While I was messing around with the wires and studying my service manual for hours, I've discovered the following:

Headlights are functional.

Reverse lights work.

Hazard lights work on the front and on the dash, but not in the rear.

A previous owner had removed the capacitor, aka flasher, for the turn signals and spliced the red and black wire together (I explored this further by temporarily separating the wires and putting the flasher for the hazards in between the wires. This resulted in the flasher - as well as the ignition coil? - constantly clicking whenever the key was in the run position. Also, before I had done this test, moving the turn signal stalk did nothing, but with the flasher connected to the red and black wire, I could hear another clicking sound from the passenger side whenever I flicked the signal stalk either direction.)

There are two pink wires that turn into one wire through a harness going to the tail lights, the connector of which in the harness was heavily corroded and broke when I disconnected the harness, so I cut the pink wires from the harness and spliced in a new connection.

I tested the brake lamp switch for continuity and there is indeed continuity.

I cleaned up the circuit board on the back of the instrument cluster and there is continuity all across.

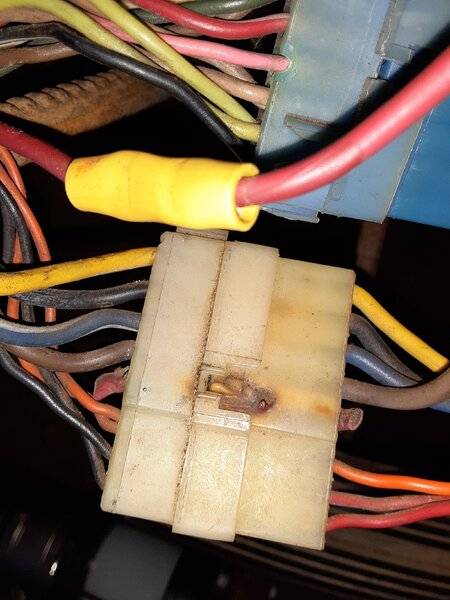

There is a white harness near the steering column that has had one thick red wire burn up in it, a previous owner had bypassed the harness by splicing the wire together.

I replaced all 6 fuses and checked the top of the fuse block for major corrosion, nothing bad enough to halt the flow of electricity.

There is a small connector located near the wiper switch (wipers don't work either btw) consisting 4 wires forming into 2 connectors, 2 orange and 2 yellow. This has always been disconnected for as long as I've had the car.

There is another loose connector that has 2 blue wires with white tracers sort of above the harness going to the tail lights.

A T shaped connector with a dark green wire and brown wire is hanging under the glove box.

Sorry for the long post, I seriously appreciate the help!

Headlights are functional.

Reverse lights work.

Hazard lights work on the front and on the dash, but not in the rear.

A previous owner had removed the capacitor, aka flasher, for the turn signals and spliced the red and black wire together (I explored this further by temporarily separating the wires and putting the flasher for the hazards in between the wires. This resulted in the flasher - as well as the ignition coil? - constantly clicking whenever the key was in the run position. Also, before I had done this test, moving the turn signal stalk did nothing, but with the flasher connected to the red and black wire, I could hear another clicking sound from the passenger side whenever I flicked the signal stalk either direction.)

There are two pink wires that turn into one wire through a harness going to the tail lights, the connector of which in the harness was heavily corroded and broke when I disconnected the harness, so I cut the pink wires from the harness and spliced in a new connection.

I tested the brake lamp switch for continuity and there is indeed continuity.

I cleaned up the circuit board on the back of the instrument cluster and there is continuity all across.

There is a white harness near the steering column that has had one thick red wire burn up in it, a previous owner had bypassed the harness by splicing the wire together.

I replaced all 6 fuses and checked the top of the fuse block for major corrosion, nothing bad enough to halt the flow of electricity.

There is a small connector located near the wiper switch (wipers don't work either btw) consisting 4 wires forming into 2 connectors, 2 orange and 2 yellow. This has always been disconnected for as long as I've had the car.

There is another loose connector that has 2 blue wires with white tracers sort of above the harness going to the tail lights.

A T shaped connector with a dark green wire and brown wire is hanging under the glove box.

Sorry for the long post, I seriously appreciate the help!