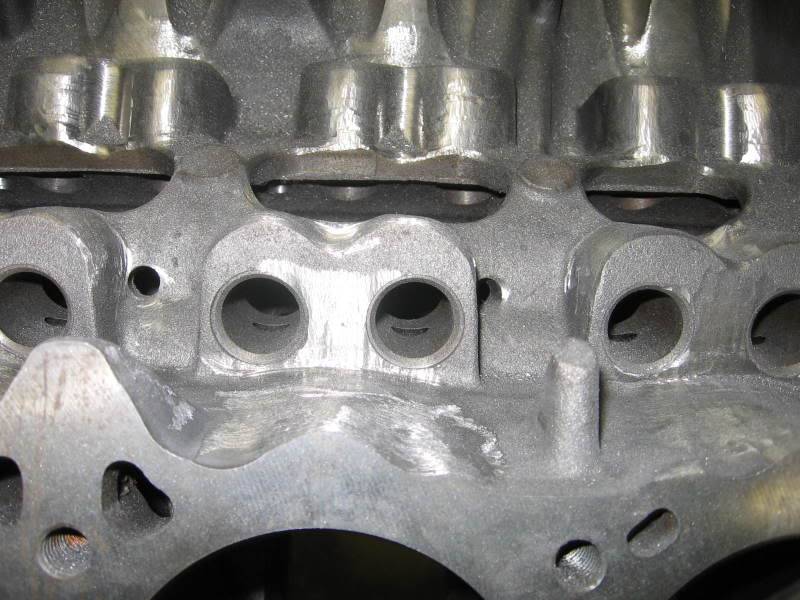

I'm using a 340 repro block for my build, and there are clearance issues when using roller lifters. And there is a choice lifter to keep the grinding to a minimum.

These are MP pieces. Crane is now the supplier for these. The 'rivets' are not as thick as other man.

A couple of shots.........

These are MP pieces. Crane is now the supplier for these. The 'rivets' are not as thick as other man.

A couple of shots.........