Mattax

Just the facts, ma'am

Not sure what you're asking, but I think you're asking about where protection is needed.

Fusible links were used to protect downstream of the battery while allowing occassional high draws for short periods of time. The battery, while only at 12.8 Volts at best, has lots of stored power - enough to turn a starter motor in the freezing cold and enough weld with! That's why the original factory design added in a fusible link to the battery feed, but not on the alternator feed. Also the alternator won't produce power if there a short that prevents the field from getting electricity.

So to figure it where your fuses should go, you need to know the flow of current in your car. This will depend on where the pump and headlight relays get power.

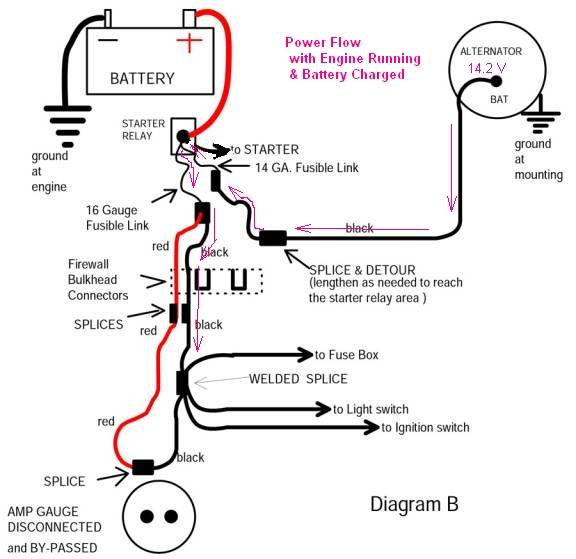

Both MAD and my diagrams above show a vehicle with the stock arrangement (no relays or additonal electric equipment). All of the power for running the car flows through the main junction (splice).

That's what the purple arrows illustrate.

You can do it yourself for any situation. Start at the highest voltage source of power, and trace where the current must flow through to get to the equipment or lights, and finally ground.

For example, do it for the starting situation. In that case the Battery positive is the highest voltage source. Start from there and follow the path(s) to where the power needs are.

Do the same now to where you've located the relay for the electric pump both for starting and for running. It makes a difference if your relays draw power from the alternator output, the fusebox or the battery positive.

Fusible links were used to protect downstream of the battery while allowing occassional high draws for short periods of time. The battery, while only at 12.8 Volts at best, has lots of stored power - enough to turn a starter motor in the freezing cold and enough weld with! That's why the original factory design added in a fusible link to the battery feed, but not on the alternator feed. Also the alternator won't produce power if there a short that prevents the field from getting electricity.

So to figure it where your fuses should go, you need to know the flow of current in your car. This will depend on where the pump and headlight relays get power.

Both MAD and my diagrams above show a vehicle with the stock arrangement (no relays or additonal electric equipment). All of the power for running the car flows through the main junction (splice).

That's what the purple arrows illustrate.

You can do it yourself for any situation. Start at the highest voltage source of power, and trace where the current must flow through to get to the equipment or lights, and finally ground.

For example, do it for the starting situation. In that case the Battery positive is the highest voltage source. Start from there and follow the path(s) to where the power needs are.

Do the same now to where you've located the relay for the electric pump both for starting and for running. It makes a difference if your relays draw power from the alternator output, the fusebox or the battery positive.

Last edited: