circlepilot

Well-Known Member

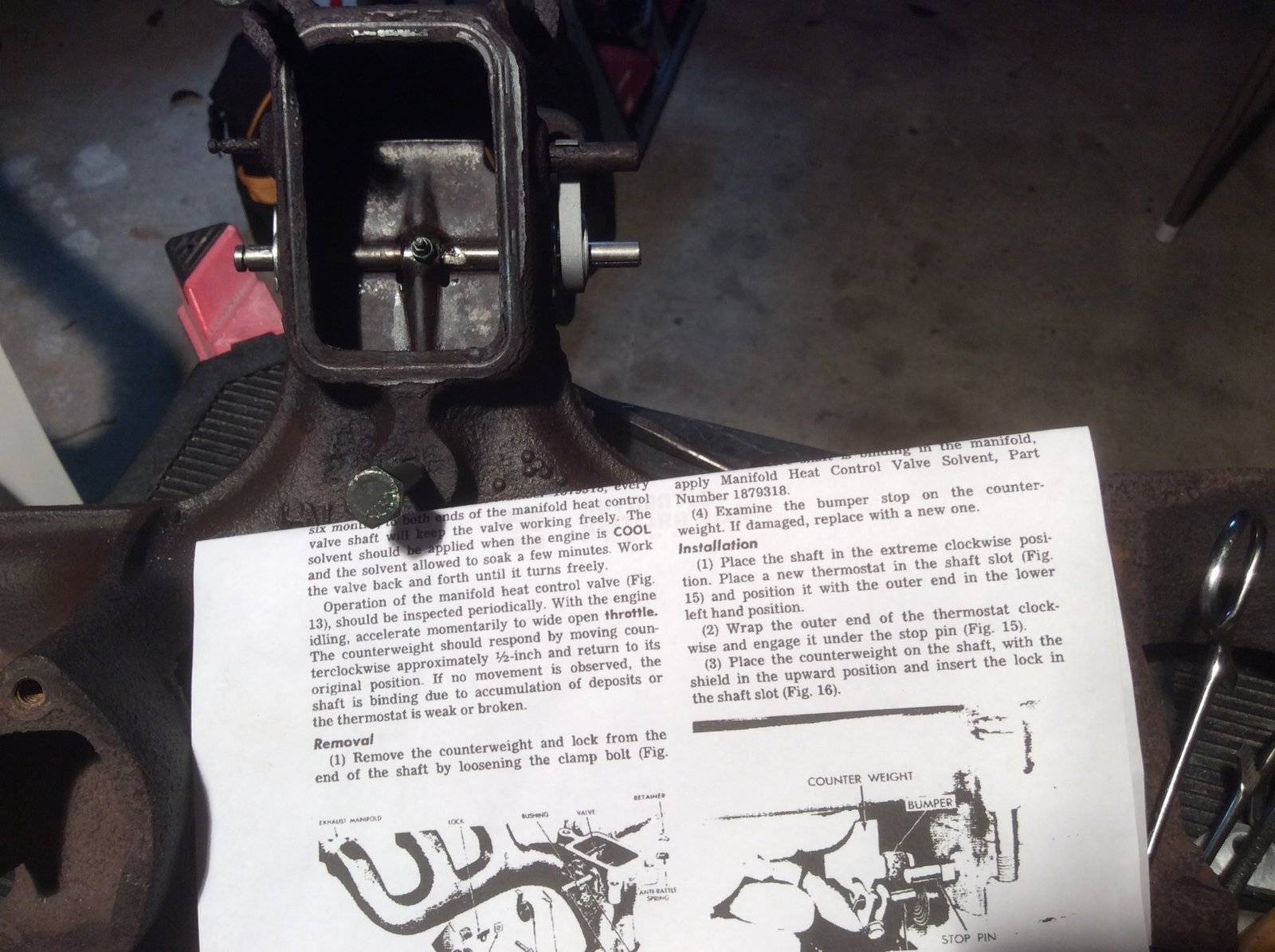

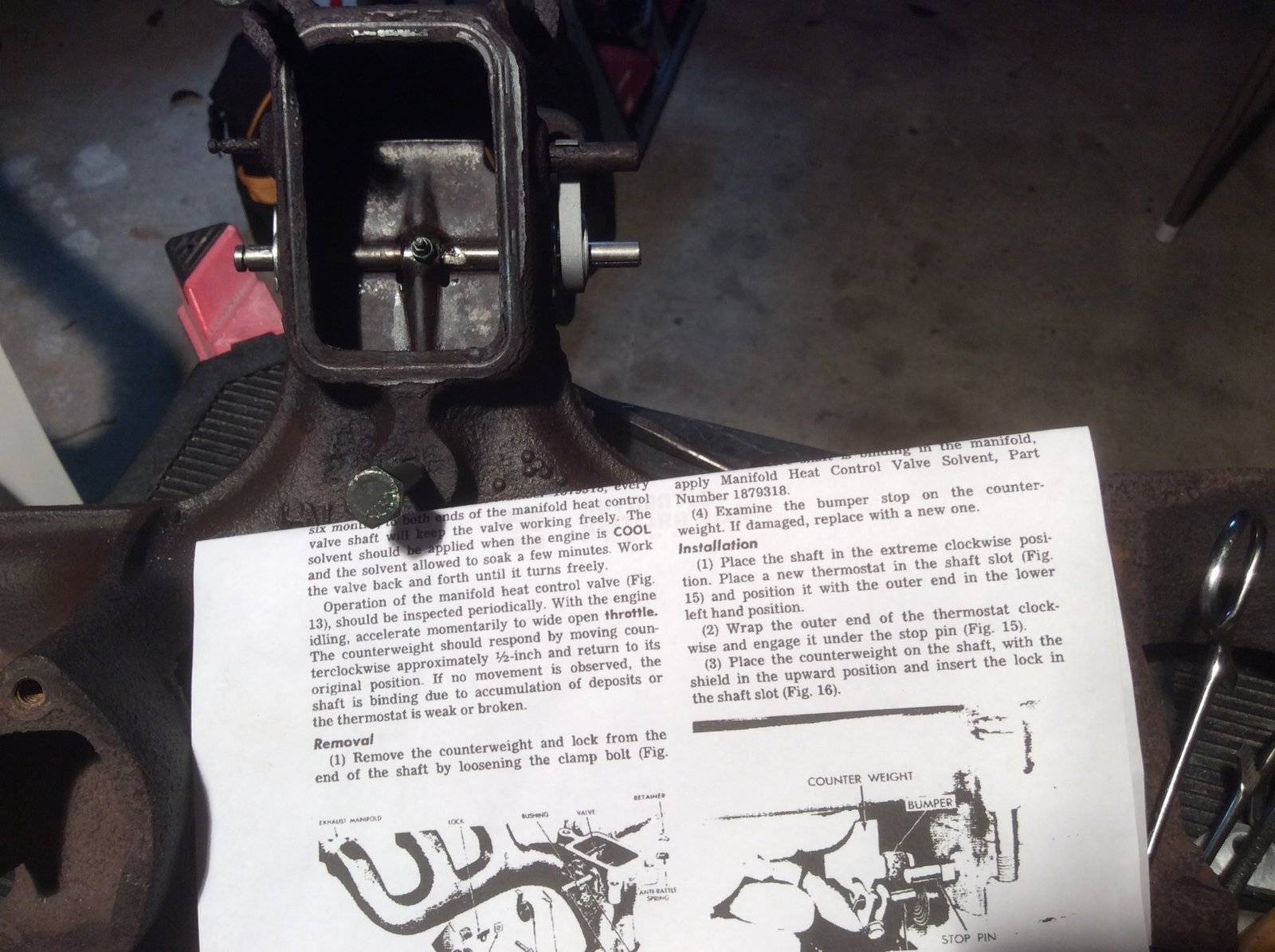

Help! I'm having a senior moment. The manifold heat control valve on my "restoration project," (65 Barracuda, Super 225) was found to be seized, further inspection showed that it had, at sometime broke loose from its shaft. I took the whole thing apart, reworked the shaft, (drilled to accommodate screw to hold the valve) cleaned the valve, installed some bushings etc. When I went to reassemble the valve, I've decided that I'm not sure I have the valve installed right, I know the shaft is installed correctly. I've checked my manual, but the position of the valve is not very clear. The picture is how I've installed the valve with the "thermostat spring" in its "loaded" condition.

Norm

Norm