I'd want more torque out of a 4" stroke 318 then 400 lbs-ft that's possible with a well put together stock stroke 318. But ultimately it's the torque at tire that matters.I like TT5.9 (Mikes) answer.

But me? I'd put a cast 4"stroker kit in the 318, get 390-395 inches, throw on some speedmaster heads, preferably bought from a black friday sale, use the intake you have, with maybe some brand of 750, use the exhaust you have. If you REALLY want to get into it...... an overdrive with a gear change. Should get you an easy to live with 400hp, 400 torque.

I would not do a 440 swap, too many things would need to be acquired and /or changed.

If you WANT a 440 powered car, to go fast in a straight line...... I'd find a slant six Duster and swap a 440 into that.

My opinion only (from a guy with a 440 swapped /6 car)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maybe I've learned a good lesson . . .

- Thread starter Vanguard15

- Start date

-

Vanguard15

Member

Thanks for the tip. I'll give them a call and find out what I can.Delta Cams is up for sale according to their website.

I would contact them as soon as possible and get as much info as you can about the cam. Lobe centerline, recommneded install, lobe design etc.

Looking at Comp's 2011 catalog there's nothing that really matches but the closest ones suggest that a converter may not be needed. Again see what Delta says. Generally cam manufactures have a sense of when non-stock converter is really needed.

Higher stall converters allow an engine to respond decently even with a less well tuned low and mid range. Its possible that with tuning a snappier response can be had from the existing setup. This takes more effort than the top end tuning but same approach, document the baseline and keep track of the changes and what they did.

Vanguard15

Member

I just looked at a Richard Holdener video and his Dodge stock 2bbl 360 van dyno'd to the wheels 155 hp and same engine out of van but fully dressed with the breather accessories and van exhaust dyno'd 225 hp flywheel. Once he did about 350 hp flywheel of upgrades it dyno'd 252 hp to the wheels, he didn't say anything about torque, but yours actually sounds about right compared to his.

That's helpful. Thanks for posting it!

Vanguard15

Member

I think about this a lot. On B-Body forums it is discussed quite a bit, but no one every seems to complete the build and post results . . . or maybe I just haven't seen them.I like TT5.9 (Mikes) answer.

But me? I'd put a cast 4"stroker kit in the 318, get 390-395 inches, throw on some speedmaster heads, preferably bought from a black friday sale, use the intake you have, with maybe some brand of 750, use the exhaust you have. If you REALLY want to get into it...... an overdrive with a gear change. Should get you an easy to live with 400hp, 400 torque.

I would not do a 440 swap, too many things would need to be acquired and /or changed.

If you WANT a 440 powered car, to go fast in a straight line...... I'd find a slant six Duster and swap a 440 into that.

My opinion only (from a guy with a 440 swapped /6 car)

Especially when on the engine dyno there was a gain 70 lbs-ft @ 2500 rpms over stock with the cam he end up using.Its interesting how much RWHP was lost below 3000 rpm with the final combo that Holdener put back into the van.

junkyardhero

Well-Known Member

- Joined

- Jan 23, 2005

- Messages

- 2,930

- Reaction score

- 4,597

if you consider that it's probably turning 200lb + of stuff after the trans it's not all that crazy. wheels, tires, brake drums, driveshaft, axle... it's the old race car saying: ounces add up to pounds.Its interesting how much RWHP was lost below 3000 rpm with the final combo that Holdener put back into the van.

Thanks! I missed that.

I don't know if this is an issue of what they did or relates to the difficulties of running inertia dynos at lower rpms.

Some differences he mentioned shouldn't have mattered (electric fan)

Maybe I also missed it, I'm assuming the airgap rpm was the final intake along with the ported heads. Not sure about the carb.

If so, it wouldn't surprise me if the ported heads are hurting velocity in the street driving rpm range.

I don't know if this is an issue of what they did or relates to the difficulties of running inertia dynos at lower rpms.

Some differences he mentioned shouldn't have mattered (electric fan)

Maybe I also missed it, I'm assuming the airgap rpm was the final intake along with the ported heads. Not sure about the carb.

If so, it wouldn't surprise me if the ported heads are hurting velocity in the street driving rpm range.

That gets back to how effective are dynos in replicating the low rpm loads?if you consider that it's probably turning 200lb + of stuff after the trans it's not all that crazy. wheels, tires, brake drums, driveshaft, axle... it's the old race car saying: ounces add up to pounds.

If the chassis dyno is anything close to repeatable, then below intestate speeds, the van was less torquey and less responsive at full throttle with the ported heads, cam, and 4 bbl than it had been as a 2 bbl. The saving grace is part throttle kickdown of the transmission.

Not sure, don't know that much about wheel dyno's, he said it worked a lot better after was his driver.Thanks! I missed that.

I don't know if this is an issue of what they did or relates to the difficulties of running inertia dynos at lower rpms.

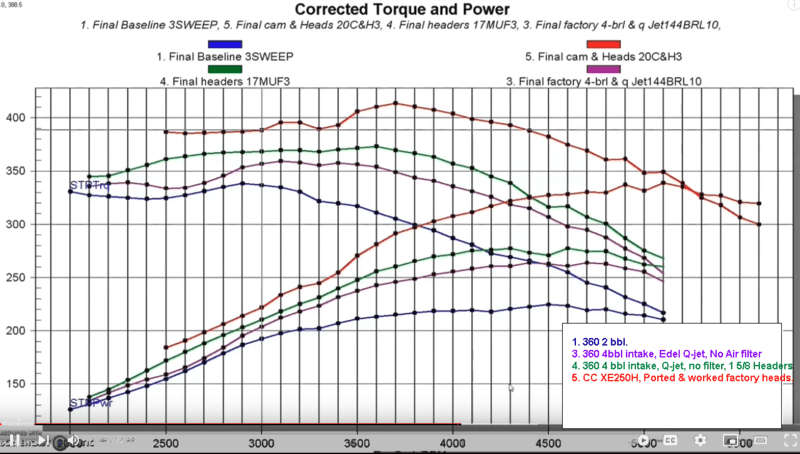

Was with the Ported heads , airgap, edelbrock q jetView attachment 1716215460

Some differences he mentioned shouldn't have mattered (electric fan)

Maybe I also missed it, I'm assuming the airgap rpm was the final intake along with the ported heads. Not sure about the carb.

he said it was minor just blended the 2.02 valve in the bowlIf so, it wouldn't surprise me if the ported heads are hurting velocity in the street driving rpm range.

wonder when back in the van if he put stock manifold exhaust back on plus breather, might also took some out of the tune.That gets back to how effective are dynos in replicating the low rpm loads?

If the chassis dyno is anything close to repeatable, then below intestate speeds, the van was less torquey and less responsive at full throttle with the ported heads, cam, and 4 bbl than it had been as a 2 bbl. The saving grace is part throttle kickdown of the transmission.

View attachment 1716215481

I just relistened. He said 'minor fluffing' of the entry and emphasized bowl work a couple times. And correct me if I'm wrong, I thought typical 360 came with 1.88 intake valves.he said it was minor just blended the 2.02 valve in the bowl

I agree - but would have thought that would have really clobbered the mid and high rpm.wonder when back in the van if he put stock manifold exhaust back on plus breather, might also took some out of the tune.

Ya they would of been orignally 1.88 but think he meant they just blended in the 2.02 valve job.I just relistened. He said 'minor fluffing' of the entry and emphasized bowl work a couple times. And correct me if I'm wrong, I thought typical 360 came with 1.88 intake valves.

junkyardhero

Well-Known Member

- Joined

- Jan 23, 2005

- Messages

- 2,930

- Reaction score

- 4,597

That gets back to how effective are dynos in replicating the low rpm loads?d

If the chassis dyno is anything close to repeatable, then below intestate speeds...

ohhh... we gonna open this up to a dyno discussion? that's deep waters. with like with eddys and currents...Thanks! I missed that.

I don't know if this is an issue of what they did or relates to the difficulties of running inertia dynos at lower rpms.

yea yea yeah! Let's dive in!ohhh... we gonna open this up to a dyno discussion? that's deep waters. with like with eddys and currents...

Or maybe the answer is simpler and we just need to take a swim in how a chassis dyno is used?

Here's my thinking this morning.

If this van has an automatic transmission (without a manual valve body) then the graph is showing both part throttle and full thottle,

and we don't know where that switches over.

When I've used a inertia dyno, the instructions are squeeze the throttle on to full throttle as quickly as possible without causing downshift.

I do this by using enough throttle to get it to upshift at a moderately high rpm and then squeeze the rest on quick so it won't downshift. Or I've run it so the 2-3 upshift is at full throttle. Then the results from the shift up are consistant. That technique isn't always going to work. On the dynojet I usually capture the at least the 2nd to 3rd shift.

So what we don't know in this chassis dyno chart is when full throttle was reached on the runs.

The software does some funky stuff when displaying the X-axis as rpm. Those points on the end of the blue line are pretty typical.

Here's some old runs of mine with full throttle 2-3 shift (again not the way its normally done AFAIK).

But the fair comparison begins at 75 mph or so.

Getting good low rpm data at full throttle with my chassis dyno is difficult at best. Especially with an automatic transmission. My dyno is a eddy brake dyno with smaller rollers (low inertia). My engine dyno does a much better job at this.

I should add the chassis dyno is still a very useful tool. Some things it does better than others.

junkyardhero

Well-Known Member

- Joined

- Jan 23, 2005

- Messages

- 2,930

- Reaction score

- 4,597

this. all of this.Getting good low rpm data at full throttle with my chassis dyno is difficult at best. Especially with an automatic transmission. My dyno is a eddy brake dyno with smaller rollers (low inertia). My engine dyno does a much better job at this.

i learned on a clayton chassis (eddy brake) and while it was consistent, low rpm was tricky. don't get me wrong, it was great for tuning and driveability issues as well as full pulls.

-