mopardude318

Well-Known Member

About 4 years ago, I had this slab poured. I thought a raised perimeter wall was a good idea at the time, I was gonna stick frame it. There were some mistakes during the build, I shoulda went with standard sizing, and shoulda had plans for the exact building and layout I wanted. I figured all that can come later.

It measures 27 feet wide by 29 feet long directly in the middle of the raised 8” wide perimeter wall.

Now I’m just gonna go with a metal building. 27x29x12 foot tall. Staying with a 3/12 pitch roof, I’ll be able to accommodate a 9 foot tall by 12 foot wide lean to, with the roof line flushed out.

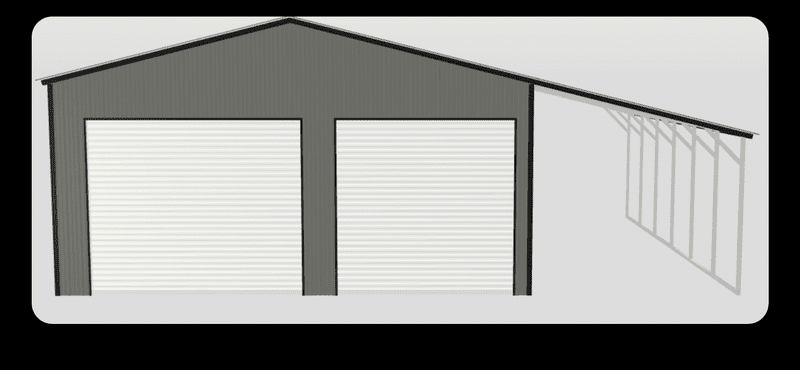

I wanted one single big roll up door in the front, something like 20 foot wide, but none of the metal building companies offered a door like that. In order for that to happen, I think I’d have to stick frame it with an engineered beam in the front.

So what they offer is two 10x10 doors, or they can do a 12x10 and a 10x10…

What would you do?

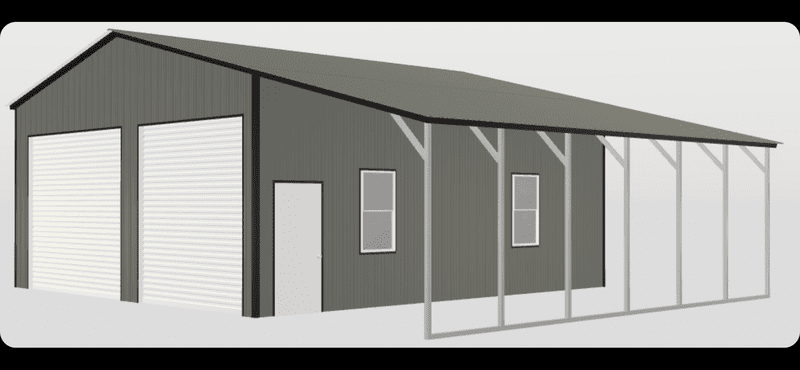

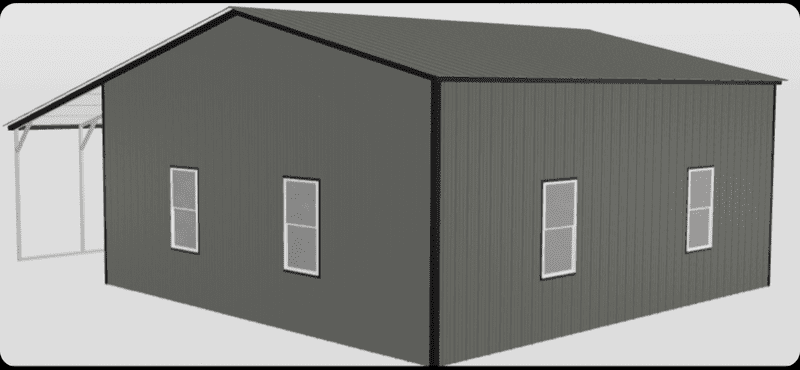

Here is some pictures of my slab and the structure rough draft on their website.

All is 26ga vertical paneling, with purlins, 12ga frame with knee braces where the truss meets the legs, and collar beams in the middle.

Six 30x53 dual pane windows and a man door.

It measures 27 feet wide by 29 feet long directly in the middle of the raised 8” wide perimeter wall.

Now I’m just gonna go with a metal building. 27x29x12 foot tall. Staying with a 3/12 pitch roof, I’ll be able to accommodate a 9 foot tall by 12 foot wide lean to, with the roof line flushed out.

I wanted one single big roll up door in the front, something like 20 foot wide, but none of the metal building companies offered a door like that. In order for that to happen, I think I’d have to stick frame it with an engineered beam in the front.

So what they offer is two 10x10 doors, or they can do a 12x10 and a 10x10…

What would you do?

Here is some pictures of my slab and the structure rough draft on their website.

All is 26ga vertical paneling, with purlins, 12ga frame with knee braces where the truss meets the legs, and collar beams in the middle.

Six 30x53 dual pane windows and a man door.