OK, you really need to make sure you buy the right length, regardless of which rockers you run. Do you know how to check pushrod length and rocker arm to valve alignment?

If not, read this**:

** anywhere in these instructions were I talk about adjustment or rocker shafts~~~you are not adjustable...ignore~~~~~~Rocker Shafts....you don't have em...ignore....replace with normal shop practices for rockers

If your engine is assembled already you need to remove all the pushrods (if they are in) and both sets of rockers (obviously) and the spark plugs should be removed.

If you only have one adjustable push-rod length checker, do the intake and then the exhaust (or exhaust then intake, does not matter).

Make sure the cam is on the base circle on the cylinder you are checking and put the adjustable pushrod(s) in place (adjusted shorter than needed) and install your rockers. You only need two on at this time, but you can leave them all on, no matter. Adjust the adjuster screws so they show about 2-3 threads protruding out the bottom of the rocker and lock them in place. If the thread count that the rocker manufacturer suggests is different than what I suggested, go with theirs.

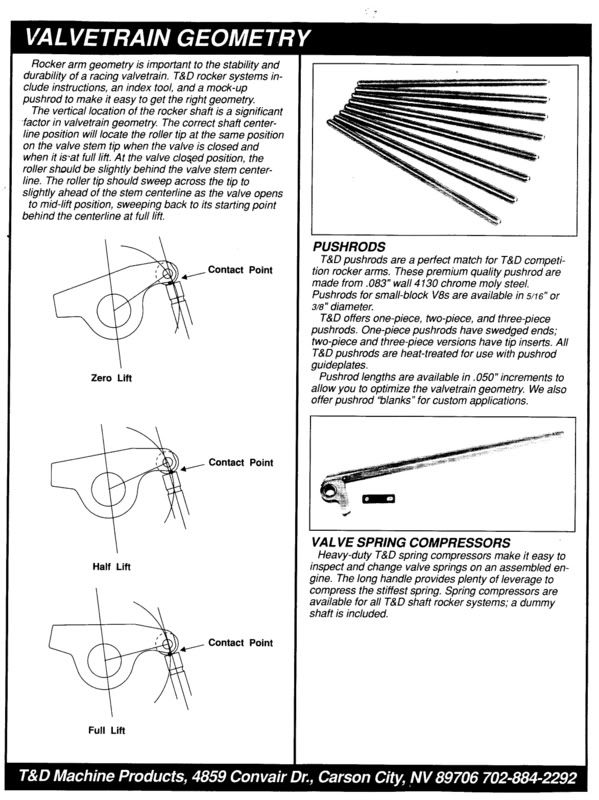

The first thing to look at is the roller tip to valve alignment. The tip should be just inboard of center on the valve at zero lift.( see Valvetrain Geometry sheet below)

If that looks good, you can move on to adjusting the pushrod(s).

Adjust the pushrod(s) to take out all lash. Do not preload the lifter(s).

Have a helper slowly rotate the engine by hand 2 full revs and watch the roller(s) on the valve(s) closely. It should start at just slightly IB of center on the base circle of the cam, roll out to just OB of center at half lift, and end up at just IB of center at full lift.

If this all works out, add .040" to the actual pushrod length. This is the correct length.

If your roller tip is not in the right spot, you either have to shim the rocker shafts up or possibly use lash caps on the valves to get the required geometry. I have never used the lash caps so maybe some of the guys that have could tell you about those, if you require them.

Final adjustment procedure after new pushrod install:

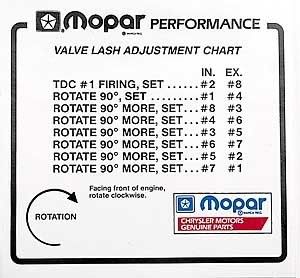

When the intake just starts to open, adjust the exhaust

When the exhaust closes, adjust the intake

also, a quicker method:

This sheet really helps, too:

I hope this helps. It is very important that everything is right on this. Once you have your new pushrods installed and adjusted, take a close look at all the valves for roller tip alignment while a helper slowly turns the engine to make sure you don't have any issues.

Good luck, Dave