Hey! I know that thread, but you are not on it here! This is about a 1406 carb...Good info, but I think the issue is/was his fuel pump mounting bolt hole.

The OP started a thread on that.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need help with edelbrock 1406 carb

- Thread starter 1968 Dart 270

- Start date

-

wheelsport

Well-Known Member

For years I praised the AFB and is derivatives. However, When I installed a 1406 on my 273 I had problems. After messing with it for several weeks, I retuned it and bought a Street Demon. Problems solved!

Dale Davies

Well-Known Member

Welll, Carter sold to Federal Mogul. Federal Mogul kept the fuel pump division and sold the carb division to Edelbrock. They introduced the AFB series Carter carbs as their Performer Series. The AVS2 line is basically the AFB/Performer carbs with some revisions. The main revision is the primary boosters are annular. This gives a couple of benefits;

1: better throttle response off idle.

2: better fuel atomization. This breaks up the fuel droplets smaller, aiding vapourization and fuel economy.

The secondary air valve is controled by an adjustable spring instead of counterweighted. The AVS2 (Air Valve Secondary) does not have secondary boosters.

The annular boosters can be installed into the Performer and probably the Carter AFB carbs. The 1406 is rated at 600 CFM, while the equivalent AVS2 1906 is rated at 650 CFM. If you change out the Performer boosters for the AVS2 annular boosters, Edelbrock recommended the 1906 base calibration to start and tune from there.

I have an Edelbrock Performer RPM Airgap manifold on my Ford 289. Airgap manifolds do not have the heat in the runners regular manifolds do. This is part of their advantage, however the lack of heat restricts vapourization. This is where the annular boosters aid in the fine atomization and vapourization of the fuel. If I was just now performing the manifold and carb swap from the 2V, I would purchase the Airgap and AVS2 carb. At the time I purchased the Performer 1406, there were no annular boosters available, 20 years ago. This is a street rod 40 Ford so gets limited miles per year. When I found out about the better atomization in the Airgap runners with the annular boosters, I started the parts chase. If interested, call The Carburetor Shop in Forest Lake, Minnesota.

1: better throttle response off idle.

2: better fuel atomization. This breaks up the fuel droplets smaller, aiding vapourization and fuel economy.

The secondary air valve is controled by an adjustable spring instead of counterweighted. The AVS2 (Air Valve Secondary) does not have secondary boosters.

The annular boosters can be installed into the Performer and probably the Carter AFB carbs. The 1406 is rated at 600 CFM, while the equivalent AVS2 1906 is rated at 650 CFM. If you change out the Performer boosters for the AVS2 annular boosters, Edelbrock recommended the 1906 base calibration to start and tune from there.

I have an Edelbrock Performer RPM Airgap manifold on my Ford 289. Airgap manifolds do not have the heat in the runners regular manifolds do. This is part of their advantage, however the lack of heat restricts vapourization. This is where the annular boosters aid in the fine atomization and vapourization of the fuel. If I was just now performing the manifold and carb swap from the 2V, I would purchase the Airgap and AVS2 carb. At the time I purchased the Performer 1406, there were no annular boosters available, 20 years ago. This is a street rod 40 Ford so gets limited miles per year. When I found out about the better atomization in the Airgap runners with the annular boosters, I started the parts chase. If interested, call The Carburetor Shop in Forest Lake, Minnesota.

Dale Davies

Well-Known Member

These carbs are known for being fuel pressure sensitive. If you research, you will find that they recommend you run a pressure regulator set at 5.5 psi or less. Without the pressure regulator when you get on it the pump will increase the pressure. When the pressure gets above 6 psi it bends the float tabs and resets the float height. I have ran into this on nearly every Edelbrock I have seen run. I rebuild mine and will be rebuilding 3 of them this week. They all get a cheap psi regulator now.

It's nice to run the fuel line on the fender away from the heat anyway. Adding a regulator this way will help keep the fuel cooler al

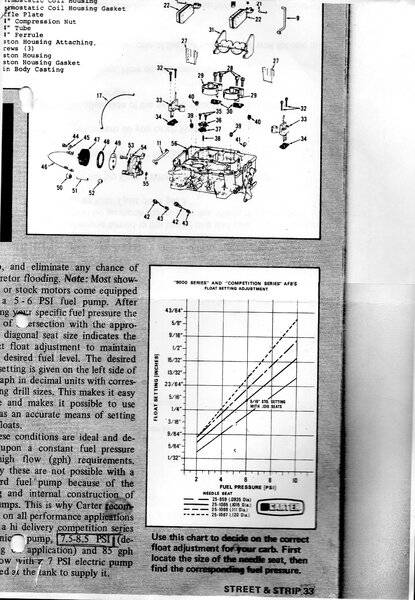

Wellll, The performance or race intended carbs come with the large n/seats in the 800 CFM carbs. A bigger carb and race engine needs the fuel.An addendum to the flooding issue.

A friend purchased an overhaul kit for a Carter #9626 carb & it came from the US [ Amazon, I think ]. It cost $US33. Junk. The hole in the acc pump shaft for the 'S' link was too small, I had to drill it out.

Here is the real kicker: the hole in the n/seat was 5/32" [ 0.156" ]!!!! I used the old seat [ looked to be 0.101" or 0.111" ] with the new needles. The new seats would almost certainly have caused flooding with high-er fuel pressures.

Since this thread was about Edel carbs, here are some real #s. Edel use small 0.093" fuel seats, for reasons known only by Edel. The area of a 0.093" hole is 0.006793 sq in; for a 0.156" hole it is 0.01913" sq in, nearly 3 times more area. So the fuel pressure acting on the needle has nearly 3 times more area to act on & cause flooding.

I can only guess why Edel uses such a low fuel level [ 7/16" float setting ] along with such small n/seats. The lower fuel level gives less chance of fuel slosh causing stumble/cutting out during braking & cornering. The change in the fuel curve [ compared to the original Carter settings ] can be adjusted with jet & air bleed changes.

Small n/seats are good for fuel control but they must be big enough to supply sufficient fuel.It is a compromise. The fuel flow chart provided by Carter is pretty useless as it gives fuel flow with the floats at a 2" drop...which is much more than it is in a working carb. So actual flow #s would be much less than the chart shows.

The Edel 800 carbs also come with the small 0.093" seats. One wonders if these will cause lean out on high HP engines, with bigger jets being fitted to fix the 'problem'.

On Carter/Edelbrock carbs you do not generally change air bleeds like you do in Holleys. Metering is adjusted with jet and metering rod changes. The metering rod springs can be changed to adjust when by vaccum the metering rods can lift for fuel enrichment. Float level.is set with the carb top off and up side down as the floats and needle and seats are installed in the top cover. If you change to a 1/2" float level, you are actually dropping the float level, backwards to Holley carbs.

Rochester Quadrajets require the carb cover be removed, but the n/seat and float stay in the float bowl main housing. Push down lightly on the float to just seat the needle in the seat. Float level is the top of the float to if I remember correctly, the top of the float bowl housing. Like the Carter/Edelbrock, bend the float arm.

What I have more problems with is fuel starvation at top of 2nd gear. At the strip, I run out of fuel more than any other problem. This is at Bandemere at 5800 feet and a DA of 7000 to 8500 most of the time. I solved this by using a Fram filter with a 1/4' vapor separator line. I run this back to the tank using the Stock emissions control line from a 70's Duster. They are availble from Fine Lines. The problem is that aluminum carbs are really not designed to work with oxygenated gasoline. The Ethanol corrodes the Al leaving oxidation residue that plugs passages and the needle/seat. Constant attention is needed to prevent corrosion so at least cleaning or rebuilding the carb frequently will help reduce problems.

Dale Davies

Well-Known Member

That

I would check the fuel pressure with a "T" in the fuel hose just before the carb. My 1406 had no pressure regulator and I had no problems.

If fuel pressure is 5# to 6#, it should be fine.

Then remove the top and remove the n/seat to check for crud. Another place to inspect if you had an improper air filter assembly, is the air bleeds in the top area of the air horn. These also act as siphon breaks when you come back to idle or shut the engine off. If this is plugged with dust, sand or other small road debris it can siphon fuel. It will drip out of the main boosters. If tbis is the case, remove the carb and dismantle. Watch the accelerator pump check valve. Then you can blow back through with carb cleaner.

A good source is;

How to Rebuild and Modify Carter/Edelbrock Carburetors, available through CarTech Books. 1-800-551-4754 or 1-651-277-1203.

Parts; The Carburetor Shop; 1-651-770-3505. They have a web site; the carburetorshop.com.

If it ran before when you bought it, I would say clean out the carb, check the needle and seat. Worst case the Carburetor shop can rebuild it. If you go this way, think about getting them to convert it to the annular boosters from the 1906. Get a wide band O2 sensor so you can drive and record readings, get a friend to write it down. Then with the 1906 or 1406 cal kit you can dial it in to close to EFI standards.

For years I praised the AFB and is derivatives. However, When I installed a 1406 on my 273 I had problems. After messing with it for several weeks, I retuned it and bought a Street Demon. Problems solved!

These carbs are known for being fuel pressure sensitive. If you research, you will find that they recommend you run a pressure regulator set at 5.5 psi or less. Without the pressure regulator when you get on it the pump will increase the pressure. When the pressure gets above 6 psi it bends the float tabs and resets the float height. I have ran into this on nearly every Edelbrock I have seen run. I rebuild mine and will be rebuilding 3 of them this week. They all get a cheap psi regulator now.

It's nice to run the fuel line on the fender away from the heat anyway. Adding a regulator this way will help keep the fuel cooler also.

These carbs are actually very simple and once innitially tuned for the engine and altitude, they retain that. Not as fussy as Holley.This is another reason I wish people would just leave these cars stock. All the mopars I had that were left factory original were ultra reliable. Chrysler engineered all those parts to work together perfectly. Then someone plays mix-n-match.

This person didn’t even have an air cleaner that fit the car correctly on it. When I brought it home I looked at it and the element had about an inch of space above it where it didn’t touch the top of the housing. Air and dust could just go right over the top of the filter and into the engine. I bought that edelbrock air cleaner because it fits the carb they had put on the car.

The plus is that the car has no rust and runs like a top until this.

Anyway the car has the factory block mounted mechanical fuel pump. Don’t know what the PSI is that it puts out,but what you say makes sense since it did it after I was on the freeway. If the floats bend under pressure sounds like that happened.why wouldn’t edelbrock make these to withstand the pressure of a normal mechanical fuel pump? The fuel line is stock. I’d prefer not to drill holes or mount it on my fender if I had a choice. The car is all original execpt for the 360 engine and the engine is factory except for the intake and carb.

So I’m curious,what do you charge to rebuild a 1406? What regulator do you recommend? Where are you located maybe I could send mine to you. Or can you recommend a better carb for the 360 for a daily driver that would work with the edelbrock intake. Something that doesn’t need a regulator?

I would check the fuel pressure with a "T" in the fuel hose just before the carb. My 1406 had no pressure regulator and I had no problems.

If fuel pressure is 5# to 6#, it should be fine.

Then remove the top and remove the n/seat to check for crud. Another place to inspect if you had an improper air filter assembly, is the air bleeds in the top area of the air horn. These also act as siphon breaks when you come back to idle or shut the engine off. If this is plugged with dust, sand or other small road debris it can siphon fuel. It will drip out of the main boosters. If tbis is the case, remove the carb and dismantle. Watch the accelerator pump check valve. Then you can blow back through with carb cleaner.

A good source is;

How to Rebuild and Modify Carter/Edelbrock Carburetors, available through CarTech Books. 1-800-551-4754 or 1-651-277-1203.

Parts; The Carburetor Shop; 1-651-770-3505. They have a web site; the carburetorshop.com.

If it ran before when you bought it, I would say clean out the carb, check the needle and seat. Worst case the Carburetor shop can rebuild it. If you go this way, think about getting them to convert it to the annular boosters from the 1906. Get a wide band O2 sensor so you can drive and record readings, get a friend to write it down. Then with the 1906 or 1406 cal kit you can dial it in to close to EFI standards.

Last edited:

1968 Dart 270

Well-Known Member

I already rebuilt the carb and it runs fine now.

I can't help but say that I have 3 Eddy 1400 series carbs (pseudo AFBs) - a 600 on a relatively stock 318 and 2 500s on a crossram on my 340, which definitely isn't stock. They have been on these cars for 13-17 years. They went on right out of the box, ran with no problem, had idle mixture and the chokes set and have been absolutely trouble free for all this time. They run great. The 340 even gets 15-16 mpg on a couple of trips last summer (I was shocked!). I know that this is anecdotal, just like the guy above that got a screwed up Performer. I think all in all that Edelbrock makes great carbs that generally run right out of the box without any significant problems.

sireland67

Well-Known Member

I have never had issues with the AFB / Eldebrock style carbs, they just work.For years I praised the AFB and is derivatives. However, When I installed a 1406 on my 273 I had problems. After messing with it for several weeks, I retuned it and bought a Street Demon. Problems solved!

I really like the Street Demons, just put a new one on my Duster. They are a set and forget about it carb.

Dale, Post #53, comments, corrections.

The Edel AVS does have secondary boosters [ original Carter did not ]. An improvement in my opinion.

Well aware of the fact that large [ 800 cfm] carbs need bigger n/s for fuel flow, but the Edel 800 cfm carbs come with the same small 093 n/s as the 500 cfm model. They DO sell a 110 high flow version.

You misread my comments about air bleeds. I was NOT recommending or suggesting air bleed changes a la Holley. What I said was, Edel for some reason, [ I offered possible reasons ] chose a very low operating fuel level for their carbs, by using a 7/16" float setting. I have never seen a 7/16" setting for an original AFB/AVS, 5/16" being very common but have seen as high 3/16" [ Ford 430 ]. That is a 1/4" difference! Because the Carter/Edel carb body dimensions relative to the spill height is the same, Edel needed to change the A/F curve to suit the lower fuel level. That is done with air bleed [ by Edel, not carb owner ] & jet changes. Most Carter 600 AFBs came with 089 pri jets. Edel 600s come with 098 or 100 pri jets, a huge increase, which I suspect is due to the lower fuel level. The Edel met rods also had a bigger spread between the cruise & power steps.

The Edel AVS does have secondary boosters [ original Carter did not ]. An improvement in my opinion.

Well aware of the fact that large [ 800 cfm] carbs need bigger n/s for fuel flow, but the Edel 800 cfm carbs come with the same small 093 n/s as the 500 cfm model. They DO sell a 110 high flow version.

You misread my comments about air bleeds. I was NOT recommending or suggesting air bleed changes a la Holley. What I said was, Edel for some reason, [ I offered possible reasons ] chose a very low operating fuel level for their carbs, by using a 7/16" float setting. I have never seen a 7/16" setting for an original AFB/AVS, 5/16" being very common but have seen as high 3/16" [ Ford 430 ]. That is a 1/4" difference! Because the Carter/Edel carb body dimensions relative to the spill height is the same, Edel needed to change the A/F curve to suit the lower fuel level. That is done with air bleed [ by Edel, not carb owner ] & jet changes. Most Carter 600 AFBs came with 089 pri jets. Edel 600s come with 098 or 100 pri jets, a huge increase, which I suspect is due to the lower fuel level. The Edel met rods also had a bigger spread between the cruise & power steps.

Dale Davies

Well-Known Member

What find you find causing the problem?

Way late to the party, but found this an interesting thread. I've been running Edelbrocks (1405, and now a 1905) on my LA360. The only problem I've ever had with it was vapor lock after I put headers on it. It started off with a 750 Edelbrock when I got the car, I forget the number, maybe a 1407. I swapped to a 1405 (600 cfm, manual choke). Got so much junk in the new filter and float bowls, I changed the gas tank. It's been spotless in the float bowls since. I've had the top of the carbs off a brazillion times, and never ripped or replaced a gasket. No leaks. But yes, you do have to be carefull with the screws, it would be easy to drop one in. And the friggin clips that hold the throttle rod and pump rod in place? They are a friggin joke. They're too small. I can barely see them, can hardly feel them with my fingers. I don't know how I haven't lost one yet, they've been removed a brazillion times too.

When I did install headers, I also welded in bungs on both collectors and run a wideband AFR gauge. The AFR gauge has been the single best thing I have ever done to the car. I'm not necessarily suggesting those who don't have one should add one. It's not the cheapest easiest thing to do. But, in the case of the OP's original problem, it would have been much clearer from the get go what the issue was. To me, it sounded like it stalled at idle due to getting too lean. Anyway, I won't guess, the OP seems to resolved the issue anyway. It would be nice to know what the problem was. Since adding the AFR gauge to my car, I have tuned tuned and tuned some more. My car now runs as close to running like it has EFI as a carb get.

Just FYI in case anyone wonders, I wound up adding an electric pump back near the tank, and continue to run a (new / replaced) mechanical pump (stock location). I added the electric pump to push fuel past the heat of the header, to stop the vapor lock. Because I'm running 2 pumps, I also added a pressure regulator and set it to 5.5 psi. I ONLY got vapor lock at the strip. And it happened consistently at about 7 seconds into the run. And the AFR gauge told the whole story. Without that AFR gauge, I would have just had to guess.

I don't know the facts about whether or not the float tabs could get bent due to fuel pressure. But my opinion is that up to 10 psi, I don't think the tabs would bend. Just my $0.02 worth, no expert on that, and I don't know the fact, just a guess.

OP, it would still be nice to hear from ya!

When I did install headers, I also welded in bungs on both collectors and run a wideband AFR gauge. The AFR gauge has been the single best thing I have ever done to the car. I'm not necessarily suggesting those who don't have one should add one. It's not the cheapest easiest thing to do. But, in the case of the OP's original problem, it would have been much clearer from the get go what the issue was. To me, it sounded like it stalled at idle due to getting too lean. Anyway, I won't guess, the OP seems to resolved the issue anyway. It would be nice to know what the problem was. Since adding the AFR gauge to my car, I have tuned tuned and tuned some more. My car now runs as close to running like it has EFI as a carb get.

Just FYI in case anyone wonders, I wound up adding an electric pump back near the tank, and continue to run a (new / replaced) mechanical pump (stock location). I added the electric pump to push fuel past the heat of the header, to stop the vapor lock. Because I'm running 2 pumps, I also added a pressure regulator and set it to 5.5 psi. I ONLY got vapor lock at the strip. And it happened consistently at about 7 seconds into the run. And the AFR gauge told the whole story. Without that AFR gauge, I would have just had to guess.

I don't know the facts about whether or not the float tabs could get bent due to fuel pressure. But my opinion is that up to 10 psi, I don't think the tabs would bend. Just my $0.02 worth, no expert on that, and I don't know the fact, just a guess.

OP, it would still be nice to hear from ya!

shep76

Well-Known Member

Old thread I know but here is my question: I have now had two big issues with flooding with carter/edelbrock carbs and needed to add regulators; didn’t these cars originally come with Carter’s? Why are fuel pressure issues now such a problem. I had to do this with a new edelbrock. And now sure enough a carter performance afb that I just got has fuel pooring down inside with 9psi pressure. It’s just a mechanical pump. What has changed?

Dale Davies

Well-Known Member

Most mechanical pumps are designed to output 5 to 7 PSI. A high volume or race oriented pump may put out more. Most modern carbs are designed to run on 5 to 7 PSI. Is your pressure guage on a Tee in the fuel line to measure running pressure? Is it possible you have gotten dirt or a flake of rust in the needle and seats?Old thread I know but here is my question: I have now had two big issues with flooding with carter/edelbrock carbs and needed to add regulators; didn’t these cars originally come with Carter’s? Why are fuel pressure issues now such a problem. I had to do this with a new edelbrock. And now sure enough a carter performance afb that I just got has fuel pooring down inside with 9psi pressure. It’s just a mechanical pump. What has changed?

shep76

Well-Known Member

Possible. I just got this car. It was sitting for years so I rebuilt the carb. I just put a vacuum/fuel gauge on the end of the fuel line and saw 9psi. Since I had this issue with an edelbrock on another engine I figured its likely a fuel pressure issue. Most people recommend no more that 4.5 psi for the edelbrock. I didn't replace the float so it may be that but I will likely try the regulator first since it is pretty common issue...too much pressure. I just still don't get it, I thought these cars all came with carter afb's from the factory.

4spdragtop

Well-Known Member

Did u chk floats for a leak? Might not be the most popular opinion, but I have never run a psi regulator and never had a psi problem.

shep76

Well-Known Member

I'll take the top off tomorrow and have a look. I just know many many people run into fuel pressure issues with carters/edelbrocks. But maybe it is a float issue but fuel pressure is the 1st troubleshooting step on most carter/edelbrock trouble shooting guides for flooding....Did u chk floats for a leak? Might not be the most popular opinion, but I have never run a psi regulator and never had a psi problem.

People believe anything magazines and stupid TV shows tell them. The fact is, the Edelbrock 1406 is one of the best selling carburetors and NOT because of its performance, but because of genius marketing. The 1406 is ANYTHING BUT a performance carburetor. They are leaner than any factory style 4 barrel. If you're trying to use one for performance purposes, you're backing up and that's just all there is to it. If you want a performance version, get the 1405. They are calibrated for performance. The 1406 is calibrated for economy.

Dale Davies

Well-Known Member

You just got the car so do not know the fuel pump. I would be checking that and your parts store for the pressure listed for the factiry replacement fuel pump. It is possible for the floats to be sinking which will be revealed with the cover off. Remove the float from the cover and set it in the full float bowl. About 1/4 to 1/3 should be above the fuel surface at least.I'll take the top off tomorrow and have a look. I just know many many people run into fuel pressure issues with carters/edelbrocks. But maybe it is a float issue but fuel pressure is the 1st troubleshooting step on most carter/edelbrock trouble shooting guides for flooding....

Dale Davies

Well-Known Member

The problem encountered is not engine performance but flooding.People believe anything magazines and stupid TV shows tell them. The fact is, the Edelbrock 1406 is one of the best selling carburetors and NOT because of its performance, but because of genius marketing. The 1406 is ANYTHING BUT a performance carburetor. They are leaner than any factory style 4 barrel. If you're trying to use one for performance purposes, you're backing up and that's just all there is to it. If you want a performance version, get the 1405. They are calibrated for performance. The 1406 is calibrated for economy.

I have a 1406 and been happy with its operation. Definately looking to economy for me.

shep76

Well-Known Member

I appreciate the advice. I’ll give that a shot. I have 9605s which is like the 1405 I believe.You just got the car so do not know the fuel pump. I would be checking that and your parts store for the pressure listed for the factiry replacement fuel pump. It is possible for the floats to be sinking which will be revealed with the cover off. Remove the float from the cover and set it in the full float bowl. About 1/4 to 1/3 should be above the fuel surface at least.

shep76

Well-Known Member

And you are correct. It is possible the guy who put the fuel pump bought a “high output” model i suppose.I appreciate the advice. I’ll give that a shot. I have 9605s which is like the 1405 I believe.

I understand completely. A lot of people don't understand that though. Not everyone looks for the same thing.The problem encountered is not engine performance but flooding.

I have a 1406 and been happy with its operation. Definately looking to economy for me.

Let's cut through the bullch*t.

- 7miles out:

Do not use an elec pump with a mech pump to stop vapour lock. It won't work...... Neither pump is designed to work with another pump. If you want to avoid vapour lock, use the elec pump by itself.........or else I have been incredibly lucky over the last 50 yrs.

- When Edel started making Carter AFBs, they changed very little. One thing NOT changed was the fuel inlet/delivery system. The parts are interchangeable. The robust design can be used up to 10 psi fuel pressure [ yes, 10 ]. Float level needs to be adjusted for [a] n/s size fuel pressure. The 5.5 psi figure bandied about for Edel carbs is the datum pressure. more pressure will raise fuel level & vice versa. Adjust jetting accordingly.

- 7miles out:

Do not use an elec pump with a mech pump to stop vapour lock. It won't work...... Neither pump is designed to work with another pump. If you want to avoid vapour lock, use the elec pump by itself.........or else I have been incredibly lucky over the last 50 yrs.

- When Edel started making Carter AFBs, they changed very little. One thing NOT changed was the fuel inlet/delivery system. The parts are interchangeable. The robust design can be used up to 10 psi fuel pressure [ yes, 10 ]. Float level needs to be adjusted for [a] n/s size fuel pressure. The 5.5 psi figure bandied about for Edel carbs is the datum pressure. more pressure will raise fuel level & vice versa. Adjust jetting accordingly.

Lean or rich are tuning issues that essentially all carbs need to be correct for a given application. The original jetting may be lean for Carter/Edelbrock carbs, but that is just a metering rod or jet away. My experience with Carters is great. My 340 FB FS was no faster with a 750 Holley than the original AVS, but the AVS got far better fuel economy than the Holley.People believe anything magazines and stupid TV shows tell them. The fact is, the Edelbrock 1406 is one of the best selling carburetors and NOT because of its performance, but because of genius marketing. The 1406 is ANYTHING BUT a performance carburetor. They are leaner than any factory style 4 barrel. If you're trying to use one for performance purposes, you're backing up and that's just all there is to it. If you want a performance version, get the 1405. They are calibrated for performance. The 1406 is calibrated for economy.

What is more of an issue today is the quality of fuel. Ethanol eats the inside of carbs if let to sit for any length of time, and ethanol destroys Viton seals causing flooding. This can happen to any carb. Ethanol also eats the plating on steel gas tanks putting rust and oxides into the fuel system, also leading to leaks.

For us, the sad thing is, ethanol does nothing for emissions or performance unless you design the whole system to be compatible with it.

-

Similar threads

- Replies

- 7

- Views

- 252

- Replies

- 24

- Views

- 788

- Replies

- 5

- Views

- 541