I am having to re-do the upper control arms bushings on my Dodge Dart due to very premature failure of the brand new front bushings (60 miles or so), the front bushings became loose and the UCA running back and forth on the front bushings.

I have oredered new bushings and I know most will say I need new UCAs but I`d like some input on the bushings I have just got in the mail, they look weird to me, pictures below.

The online shop where I bought them said they were going to send either moog or federal mogul made in USA, but that is what I got.

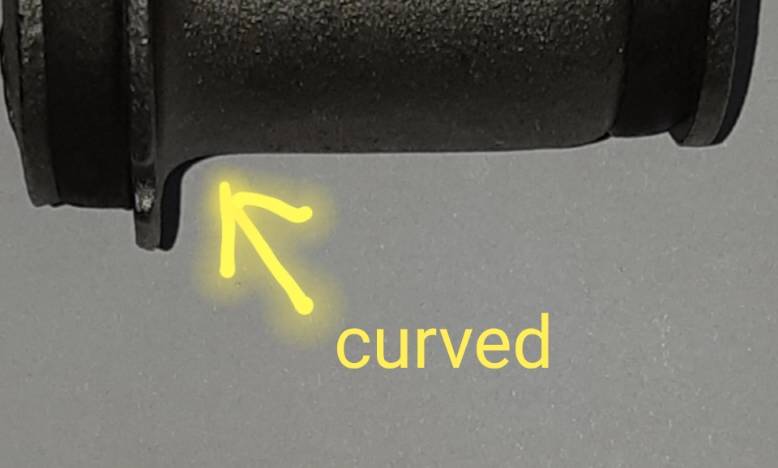

These weird looking bushings are off specs, the external diameter in the middle is about 0.5 mm (0,02") larger than the stock bushing I had bought before and the end where it is supposed to touch the UCA is curved resulting in a larger diameter, so the bushing will not be pressed all the way in the UCA bore.

I believe my upper control arms bores where the bushings are installed are a bit worn out but the new bushings were pressed about 2 months ago using a manual press in a way I could fell how much force it was required to push them in place and I did not notice much difference when pressing the front and rear bushings in the UCA, they both required some good amount of effort to be pressed in so I believed they would be ok.

These UCAs have the metal collar/sleeve pressed on the rear bushing, which works very well to lock the bushing in place. I say that because I put back the collars on the rear bushings and they did not move, but this is what happened to the front bushings:

Upper control arm bushing extra part?

I have already ordered new real moog UCA bushings and will probably try to return the weird ones above.

I also found a standard size metal pipe to fabricate the collars/sleeves for the front bushings too. They will fit tight.

My other question would be:

Using the OEM Upper Control Arm and centered rubber bushings, trying to align to get the + Caster, puts the UCA in a twisted positition in the mounts, the front of the UCA will be all out and the rear all in to start with.

I am trying to get about 0.6 to 0.8 degree Negative Camber and at least 1,5 Positive Caster, which I was able to before the front bushings on the UCA got loose.

IMO, the twisted UCA position for + Caster makes the bushings not paralell to the frame and that may cause some more stress to the bushings.

I`d be interested in knowing what alignment numbers we can expect to get using these OEM parts and if the max Positive Caster position on the UCA can cause premature failure on the OEM bushings. Thanks for any comments.

I have oredered new bushings and I know most will say I need new UCAs but I`d like some input on the bushings I have just got in the mail, they look weird to me, pictures below.

The online shop where I bought them said they were going to send either moog or federal mogul made in USA, but that is what I got.

These weird looking bushings are off specs, the external diameter in the middle is about 0.5 mm (0,02") larger than the stock bushing I had bought before and the end where it is supposed to touch the UCA is curved resulting in a larger diameter, so the bushing will not be pressed all the way in the UCA bore.

I believe my upper control arms bores where the bushings are installed are a bit worn out but the new bushings were pressed about 2 months ago using a manual press in a way I could fell how much force it was required to push them in place and I did not notice much difference when pressing the front and rear bushings in the UCA, they both required some good amount of effort to be pressed in so I believed they would be ok.

These UCAs have the metal collar/sleeve pressed on the rear bushing, which works very well to lock the bushing in place. I say that because I put back the collars on the rear bushings and they did not move, but this is what happened to the front bushings:

Upper control arm bushing extra part?

I have already ordered new real moog UCA bushings and will probably try to return the weird ones above.

I also found a standard size metal pipe to fabricate the collars/sleeves for the front bushings too. They will fit tight.

My other question would be:

Using the OEM Upper Control Arm and centered rubber bushings, trying to align to get the + Caster, puts the UCA in a twisted positition in the mounts, the front of the UCA will be all out and the rear all in to start with.

I am trying to get about 0.6 to 0.8 degree Negative Camber and at least 1,5 Positive Caster, which I was able to before the front bushings on the UCA got loose.

IMO, the twisted UCA position for + Caster makes the bushings not paralell to the frame and that may cause some more stress to the bushings.

I`d be interested in knowing what alignment numbers we can expect to get using these OEM parts and if the max Positive Caster position on the UCA can cause premature failure on the OEM bushings. Thanks for any comments.

Last edited: