Baffles made. No need to go buy some itty bitty screws to hold them in place

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PCV Port

- Thread starter DentalDart

- Start date

-

512Stroker

We are all here because we are not all there.

Loctite the screws in so they dont rattle out.Baffles made. No need to go buy some itty bitty screws to hold them in place

View attachment 1715500687

Loctite the screws in so they dont rattle out.

That's what I planned on doing

yellow rose

Overnight Sensation

If you have adjustable rockers, make sure the adjusters don’t come up and smack your baffle.

If you have adjustable rockers, make sure the adjusters don’t come up and smack your baffle.

Good looking out! I have stock rockers right now, how would I check if they hit the baffle? The metal is a super thin sheet metal I had lying around and I'm mounting it flush to the screw holes (not pre tapped for any particular screw type). I did the same thing that Johnny Mac did just not as pretty.

yellow rose

Overnight Sensation

Good looking out! I have stock rockers right now, how would I check if they hit the baffle? The metal is a super thin sheet metal I had lying around and I'm mounting it flush to the screw holes (not pre tapped for any particular screw type). I did the same thing that Johnny Mac did just not as pretty.

The stock rockers won’t ever hit that baffle. It’s the adjuster screws on adjustable rockers that could hit it. The baffle that comes with those usually just covers two rockers and the hole in the valve cover should be centered over that pair of rockers. Just something to check for when you do switch to adjustable rockers. BTDT.

DrCharles

Well-Known Member

Nice work.

I made a pair of baffles like that once (and loctited the screws in) for my MP cast covers. They work fine.

A couple weeks later, while looking for a different part, I found the baffles that had come with the covers Looked just about the same, too!

Looked just about the same, too!

I made a pair of baffles like that once (and loctited the screws in) for my MP cast covers. They work fine.

A couple weeks later, while looking for a different part, I found the baffles that had come with the covers

The stock rockers won’t ever hit that baffle. It’s the adjuster screws on adjustable rockers that could hit it. The baffle that comes with those usually just covers two rockers and the hole in the valve cover should be centered over that pair of rockers. Just something to check for when you do switch to adjustable rockers. BTDT.

Adjustable rockers? Me? No way Jose, I dont want to take all of this apart again any time soon! Lol.

Your baffles are perfect! Big enough to do the job and that's it. Better than the ones Mopar Performance sent with them.

Tried to screw in my baffles, small 12 x 1/2 in sheet metal screw and popped 2 of the tabs. What the actual ****!

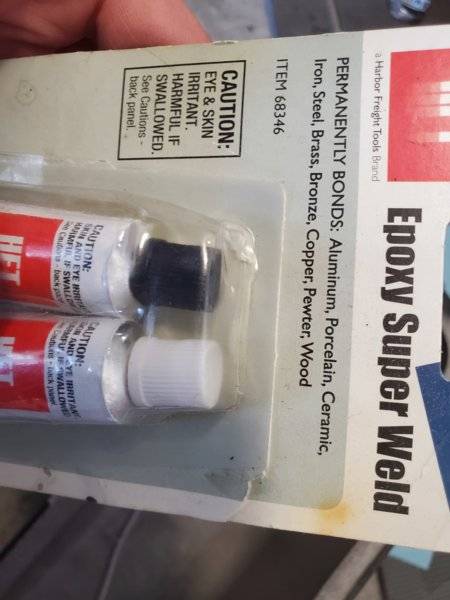

I'm kind of lost at what to do now. The #10 screws were to small for the hole, the 12's seemed just right so idk what to do now. Epoxy weld it all or I dont have another idea as I dont weld or have a welder.

I'm kind of lost at what to do now. The #10 screws were to small for the hole, the 12's seemed just right so idk what to do now. Epoxy weld it all or I dont have another idea as I dont weld or have a welder.

yellow rose

Overnight Sensation

I used a self tapping screw but I can’t remember the size...may have been metric. If you can get two screws in there with LOCTITE I wouldn’t worry about it. One screw is iffy at best.

Gotta love working on cars...it’s always something.

Gotta love working on cars...it’s always something.

67dartgtgo

Well-Known Member

Jeg’s mopar cast valve cover PCV grommet and plug.

You won’t need the plug.

I’d use this in place of the twist cover and add oil through the breather.

https://www.jegs.com/i/JEGS/555/50358/10002/-1

You won’t need the plug.

I’d use this in place of the twist cover and add oil through the breather.

https://www.jegs.com/i/JEGS/555/50358/10002/-1

Jeg’s mopar cast valve cover PCV grommet and plug.

You won’t need the plug.

I’d use this in place of the twist cover and add oil through the breather.

https://www.jegs.com/i/JEGS/555/50358/10002/-1

It's for the baffles.

I used a self tapping screw but I can’t remember the size...may have been metric. If you can get two screws in there with LOCTITE I wouldn’t worry about it. One screw is iffy at best.

Gotta love working on cars...it’s always something.

These are sheet metal self tapping screws. I'm going to try and see if I can get 1 screw in maybe the next size down a size 10 and some loctite. Then if this epoxy super weld holds nicely I'll add screws in those holes too... if it does hold tight I may be able to lay a thin bead along a couple of the edges too.

This just sucks. And is just what the Dr ordered apparently

A56

Street Survivor

They sell baffle kits for those valve covers. Just paid $9.95 for mine on Ebay, and these twist in breathers $42.00OReillys and autozone only had push on caps. I bought one but dont know it it will work as the grommet doesn't cover the full opening.

I took the gasket off my twist on cap put it on the bottom of the push on pcv filter cap then use grommet to hold everything in place on bottom side of valve cover. It's pretty tight but I think a twist on will be better to get.

View attachment 1715499989

View attachment 1715499990

View attachment 1715499991

View attachment 1715501585

Last edited:

Tried to screw in my baffles, small 12 x 1/2 in sheet metal screw and popped 2 of the tabs. What the actual ****!

I'm kind of lost at what to do now. The #10 screws were to small for the hole, the 12's seemed just right so idk what to do now. Epoxy weld it all or I dont have another idea as I dont weld or have a welder.

View attachment 1715501548

View attachment 1715501549

View attachment 1715501550

Yes or JB weld! you do not want them dropping. Make sure it is Oil and Automotive compatible!

67dartgtgo

Well-Known Member

Oops. Thought you were still looking for the pcv fix.It's for the baffles.

They sell baffle kits for those valve covers. Just paid $9.95 for mine on Ebay

View attachment 1715501585

I know they do. I looked at them and thought of getting them but I had some sheet metal laying around and made some. Then all I'd have to do is screw them in, except when screwing them in the tabs busted.

And do not use power tools!

Yes or JB weld! you do not want them dropping. Make sure it is Oil and Automotive compatible!

Idk if it is automotive oil compatible. Doesn't say on the box. I have JB weld as well. This is the current state with the epoxy weld.

It's a little hard to see but the screws didnt tap to far into the aluminum tab but was most likely from the pressure around the circumference of the tabs.

512Stroker

We are all here because we are not all there.

I used JB weld to fix the oil pan on Russian diesel tractor it's still in service 20 years later.Idk if it is automotive oil compatible. Doesn't say on the box. I have JB weld as well. This is the current state with the epoxy weld.

It's a little hard to see but the screws didnt tap to far into the aluminum tab but was most likely from the pressure around the circumference of the tabs.

View attachment 1715501596

View attachment 1715501598

View attachment 1715501599

View attachment 1715501601

That JB clear is just regular epoxy probably good stuff but I know the regular grey JB works in oil.

I used JB weld to fix the oil pan on Russian diesel tractor it's still in service 20 years later.

That JB clear is just regular epoxy probably good stuff but I know the regular grey JB works in oil.

Happy you said this. I actually went and got some jb steel reinforced weld, and rebuild the tabs essentially. I'll drill and tap the holes tomorrow and we will go from there I guess. I cant start the car until tomorrow anyways because I have to wait for the man to make it all happen.

A56

Street Survivor

It may work great, but I'd always worry about that coming apart in there.

I would not. They assemble cars with similar anymore. Just make sure to follow the directions.

It may work great, but I'd always worry about that coming apart in there.

Me too!!! I really have no other ideas other than to drill out one of the other holes and mount on the other side leaving this side as the fuel filler only hole.

This is why I should stick to fixing teeth and not cars

-

Similar threads

- Replies

- 7

- Views

- 432

- Replies

- 5

- Views

- 657

- Replies

- 3

- Views

- 201