1968 Dart 270

Well-Known Member

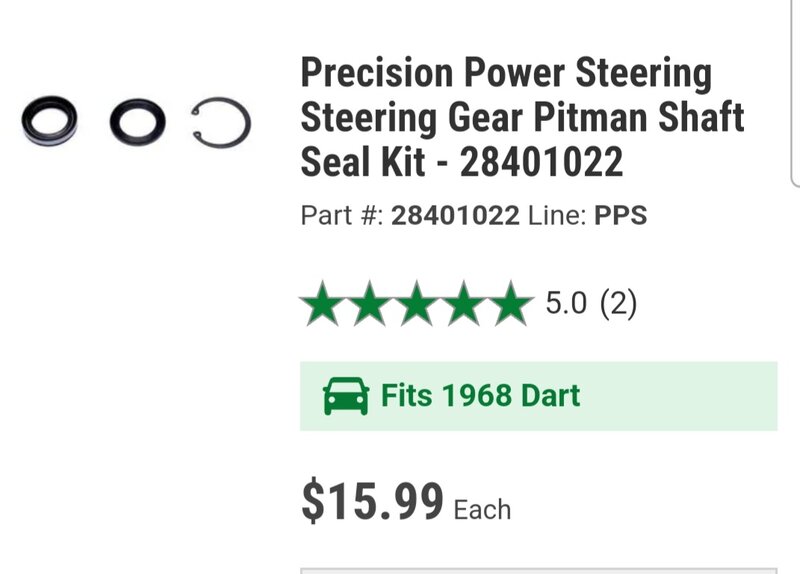

Hi,My 68 Dart is leaking steering fluid from the pitman shaft seal. I bought this seal kit today from O'Reilly to fix it this weekend. Can anyone here whose done this offer any advice as to the best way to do this,what tools to use to remove and drive the seals in. What pitman puller I will need. I've read you can use the pressure from the power steering pump to blow the seals out off the shaft without a puller. Any advice would be appreciated.