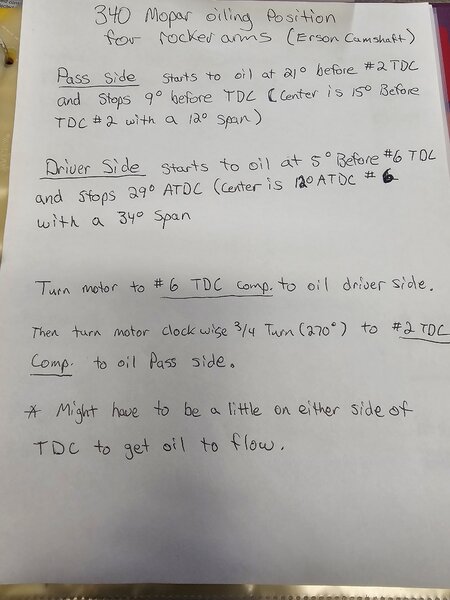

I have a 340 on the dyno today and was priming the engine. In the past I have just turned the engine slowly until I hit the position that oiled the rockers for each bank. Today I took time to document where those positions are on this engine. This was a 340 with an erson cam. Does this coincide with what others have found?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Priming 340 engine and rocker arm oiling.

- Thread starter 92b

- Start date

-

Inertia

Well-Known Member

Can someone with "the power" sticky this please .

Let's let it play out first. The oil passages in the block are all the same. No one knows if the passage in the cam is consistent between cams and manufacturers.Can someone with "the power" sticky this please .

Let's let it play out first. The oil passages in the block are all the same. No one knows if the passage in the cam is consistent between cams and manufacturers.

THIS^^^. They don’t have to be in the same location relative to the cam key. They just have to have the correct degrees of spread between the two holes.

Correct on this assumption. @4spdragtop and I went back and forth trying to figure out where his oiling events were taking place. Turns out, his were in fact 28* different than mine.THIS^^^. They don’t have to be in the same location relative to the cam key. They just have to have the correct degrees of spread between the two holes.

Last edited:

Does anyone know someone that grinds cams? They were probably just put in a V block under a drill press. They were probably not indexed. They didn't need to be.

4spdragtop

Well-Known Member

Yep, scratched our heads for a while on that one lol.

My pass side oiled @118* BTDC #1 Compression.

The drive side 8* BTDC #1 Exhaust.

I also found I was getting approx 40* of oiling.

I don't think it matters on "when" it happens in the rotation, or the spread between the 2 as long as holes line up.

Camshaft oil timing to shafts

My pass side oiled @118* BTDC #1 Compression.

The drive side 8* BTDC #1 Exhaust.

I also found I was getting approx 40* of oiling.

I don't think it matters on "when" it happens in the rotation, or the spread between the 2 as long as holes line up.

Camshaft oil timing to shafts

THIS^^^. They don’t have to be in the same location relative to the cam key. They just have to have the correct degrees of spread between the two holes.

Correct on this assumption. @4spdragtop and I went back and forth trying to figure out where his oiling events were taking place. Turns out, his were in fact 28* different than mine.

Yep, just a squirt when the holes align. You don't need a lot of oil up top. Enough to lube the rockerson the shaft and pushrod cups. It does cool the valve springs a bit but they don't need to bathe in it. No need to flood the top end and have it run down the guides. That happens anyway. The more oil up top, the less in the pan for the crank and bearings.Yep, scratched our heads for a while on that one lol.

My pass side oiled @118* BTDC #1 Compression.

The drive side 8* BTDC #1 Exhaust.

I also found I was getting approx 40* of oiling.

I don't think it matters on "when" it happens in the rotation, or the spread between the 2 as long as holes line up.

Camshaft oil timing to shafts

I was surprised that the pass side had 12 degrees of oiling and the driver side had 34 degrees of oiling. I'm not sure what caused this and I don't think it will be a problem. Also it's not my motor. When the opportunity presents itself on one of my own motors I will mock the cambearings to the camshaft to see how well the holes match.

It wouldn't surprise me if different cores are timed differently. Also I think how the cam is timed to the crankshaft will have an effect on the oil timing even if the holes are the same on the cam.

It wouldn't surprise me if different cores are timed differently. Also I think how the cam is timed to the crankshaft will have an effect on the oil timing even if the holes are the same on the cam.

TT5.9mag

Two atmospheres are better than one

It absolutely will. You’re using the damper to measure. So if the cam is moved around the oil timing will move around in relation to your measuring device.Also I think how the cam is timed to the crankshaft will have an effect on the oil timing even if the holes are the same on the cam.

I think you've hit on something here. I remember when 70aarcuda (Tony) (RIP) first posted his version. I found it to be pretty much spot on. But then I started seeing variations.Let's let it play out first. The oil passages in the block are all the same. No one knows if the passage in the cam is consistent between cams and manufacturers.

I wonder if the cam cores are drilled before the cam grinders receive them?Does anyone know someone that grinds cams? They were probably just put in a V block under a drill press. They were probably not indexed. They didn't need to be.

That could be. Good question.I wonder if the cam cores are drilled before the cam grinders receive them?

Offering a possible answer to my own question. Why is the oil duration different on each bank? On the side that has less oil duration, maybe the oil holes were not lined up longitudinally or front to back.

Offering a possible answer to my own question. Why is the oil duration different on each bank? On the side that has less oil duration, maybe the oil holes were not lined up longitudinally or front to back.

I don’t think there should be side to side variations. My cam will be here Thursday. I’ll see if I can measure it up.

I probably wasn't very clear about the hole misalignment longitudinally. If I wasn't hopefully this picture will clear it up. Please excuse the sloppiness.I don’t think there should be side to side variations. My cam will be here Thursday. I’ll see if I can measure it up.

I didn’t build the engine or install the bearings.Did you build the engine? Or install the cam bearings? The bearing on the side that has less oil timing could be clocked slightly off and partially blocking the feed hole.

I may not be understanding correctly but if by feed hole you mean the alignment between the block and bearing then I don’t think that would have an effect on the duration or timing but more of an effect on the volume depending on how far off the alignment is and assuming the hole in the block is the restriction up to that point.

TT5.9mag

Two atmospheres are better than one

That’s exactly what I was talking about and I would think it would effect both the timing (duration) and the volume.I didn’t build the engine or install the bearings.

I may not be understanding correctly but if by feed hole you mean the alignment between the block and bearing then I don’t think that would have an effect on the duration or timing but more of an effect on the volume depending on how far off the alignment is and assuming the hole in the block is the restriction up to that point.

You might be right but i'm not seeing it. Can you explain how it could do that.

TT5.9mag

Two atmospheres are better than one

If the cam bearing is pressed to far in or not in far enough but still centered it would effect only the volume. But if the bearing is pressed in rotated X number of degrees from centered with the hole it would affect timing and volume. At least I’m my tiny little brain.You might be right but i'm not seeing it. Can you explain how it could do that.

I agree. But I would make the distinction between timing and duration.

In your example with the bearings pressed in too far or not far enough this would affect duration. And it could possiblly volume in two different ways.

It could affect volume if the misalignment causes a restriction that is smaller than the passage sizes that supply oil to the bearing.

And it will affect volume if the misalignment in the block causes a front to rear misalignment with the camshaft oiling hole because the duration will be decreased.

And to complicate it even more if the the total area at the camshaft to bearing interface is smaller than the misalignment at the block to bearing interface it now becomes the point of restriction causing less flow and not the misalignment at the block.

In the second example where the misalignment is at the block and bearing where the bearing is over rotated, if the misalignment is a restriction point smaller than any where else in the system it could reduce volume. It also will change timing. But it would not change duration assuming the bearing hole and camshaft hole are lined up front to back.

When you think about the misalignment between the cam bearing and the block, it only becomes a restriction at the brief moment when the camshaft hole and the bearing hole are rotated to the point of alignment where the uncovered area is larger than the uncovered area at the bearing and block misalignment.

I could be wrong about any part or even all of this.

In your example with the bearings pressed in too far or not far enough this would affect duration. And it could possiblly volume in two different ways.

It could affect volume if the misalignment causes a restriction that is smaller than the passage sizes that supply oil to the bearing.

And it will affect volume if the misalignment in the block causes a front to rear misalignment with the camshaft oiling hole because the duration will be decreased.

And to complicate it even more if the the total area at the camshaft to bearing interface is smaller than the misalignment at the block to bearing interface it now becomes the point of restriction causing less flow and not the misalignment at the block.

In the second example where the misalignment is at the block and bearing where the bearing is over rotated, if the misalignment is a restriction point smaller than any where else in the system it could reduce volume. It also will change timing. But it would not change duration assuming the bearing hole and camshaft hole are lined up front to back.

When you think about the misalignment between the cam bearing and the block, it only becomes a restriction at the brief moment when the camshaft hole and the bearing hole are rotated to the point of alignment where the uncovered area is larger than the uncovered area at the bearing and block misalignment.

I could be wrong about any part or even all of this.

Last edited:

I must admit, I've installed literally hundreds of sets of cam bearings, I'm sure. In all those, I've never seen a set that lined up all of the holes on an individual perfectly. I bet it would be a good idea to get a long drill bit and run down the oil holes and drill the oil holes in the bearings out to the size of the holes in the block. Sure couldn't hurt.

-

Similar threads

- Replies

- 49

- Views

- 2K

- Replies

- 7

- Views

- 446

- Replies

- 1

- Views

- 176