Pentastar318

Member

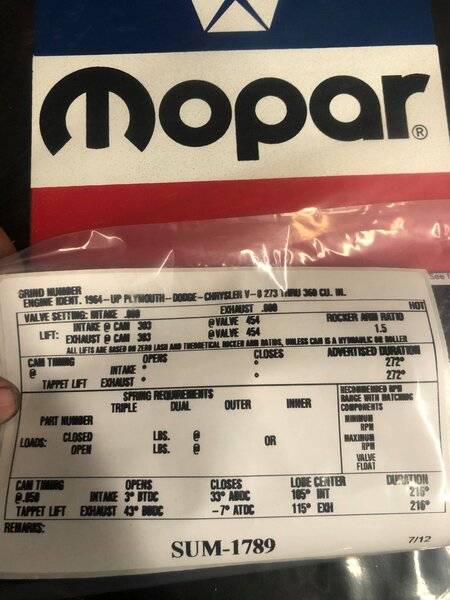

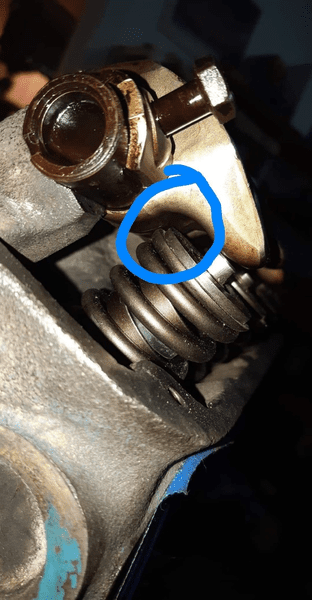

Hi everyone, I changed my Cam in my 318 and the recommended springs with this Cam Here's the problem I have my springs that are too big and are affecting my rocker arms Does anyone have a solution for my springs Guide me on this PROBLEM I want to keep my original rocker arms so I don't touch my geometry if possible I'd like to have constructive answers please, YOU KNOW A SOLUTION FOR ME! ITS CURRENT SPRINGS ARE TRICKFLOW 16901-16 THANKS YOU!