Chryslerkid

Well-Known Member

Hi guys,

I am getting ready to take off my Clifford intake manifold and headers in order to try and fix a leak I am having. I believe it's due to the stock gasket.

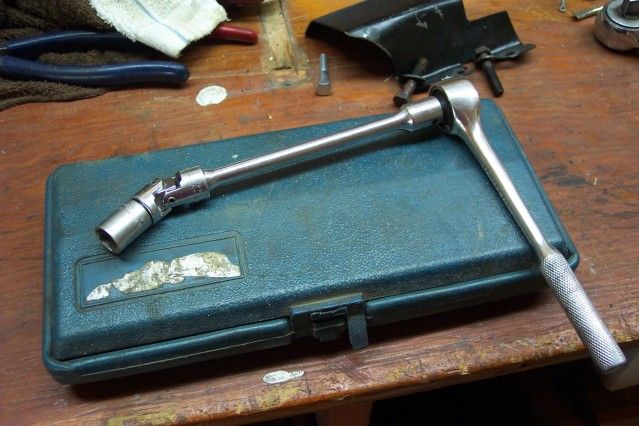

I recall having a lot of difficulty reaching some of the nuts with the tools that I currently own. Can anyone tell me what kind of tool I need to make this job easier? There is also one nut on the top center portion of the intake manifold that I could never torque down properly because of clearance issues. Anyone know what I'm talking about? If possible could you post pictures of the tools required? Thanks!

I am getting ready to take off my Clifford intake manifold and headers in order to try and fix a leak I am having. I believe it's due to the stock gasket.

I recall having a lot of difficulty reaching some of the nuts with the tools that I currently own. Can anyone tell me what kind of tool I need to make this job easier? There is also one nut on the top center portion of the intake manifold that I could never torque down properly because of clearance issues. Anyone know what I'm talking about? If possible could you post pictures of the tools required? Thanks!