ragtopfury

Well-Known Member

We are not doing anything to it until late Spring, but sometimes I just think ahead. It's what I do.

Never being a body man, but having enough amateur skill to be dangerous, answer me this with your thoughts....

The Dart Sport we let my 14 year old son bring home needs a roof. We expected that. The whole front edge of the roof is packed with Bondo. This was NOT a vinyl top car, believe it or not. All along the drip rails and around the rear window are still amazingly solid.

I have already brought home a Duster shell donor carcass.

I imagine the better job in the end would be to re-skin the whole roof, as opposed to making a seam all the way from drip rail to drip rail 8-10 inches back from the front to just replace the front edge. Correct? I mean, keeping the flat roof from warping seems it would be a ***** in my mind.

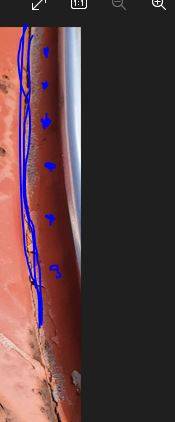

My only other question is this - After digging out the seam sealer in the drip rail, Do I cut the skin at the blue line, or drill out all the spot welds all the way down both sides?

I had never done full quarters before, until we built Jake's 65 B'cuda in 2013. So I'm not afraid to tackle the roof, just want to make sure I'm go about it in the right direction.

Never being a body man, but having enough amateur skill to be dangerous, answer me this with your thoughts....

The Dart Sport we let my 14 year old son bring home needs a roof. We expected that. The whole front edge of the roof is packed with Bondo. This was NOT a vinyl top car, believe it or not. All along the drip rails and around the rear window are still amazingly solid.

I have already brought home a Duster shell donor carcass.

I imagine the better job in the end would be to re-skin the whole roof, as opposed to making a seam all the way from drip rail to drip rail 8-10 inches back from the front to just replace the front edge. Correct? I mean, keeping the flat roof from warping seems it would be a ***** in my mind.

My only other question is this - After digging out the seam sealer in the drip rail, Do I cut the skin at the blue line, or drill out all the spot welds all the way down both sides?

I had never done full quarters before, until we built Jake's 65 B'cuda in 2013. So I'm not afraid to tackle the roof, just want to make sure I'm go about it in the right direction.