This is kind of a long story so I'm

Going to attempt to keep it short and sweet.

91 Dodge w150 short bed 4x4 Truck.

300hp crate 360 Magnum, around 20-25k miles on engine.

Was running a Mopar distributor from FBO systems, kept having issues with the advance plate wobbling around, reluctor teeth smacking the pick up coil post.

Long story short I ditched that unit and bought a firecore 50 electronic vacuum advance unit.

First firecore unit ran extremely rough at 2500 rpm with initial timing at 18 degrees and total timing at 34 degrees and an additional 12 degrees from vacuum advance.

When I dis-connected the vacuum advance the (rough spot went away)

That led me to believe it was a rotor phasing issue.

So I drilled a 5/8 hole behind the number one tower on a spare distributor cap I had laying around and checked the rotor.

Sure enough it was out of phase.

Sent the unit back to firecore and firecore sent me a second unit.

Checked the phase on the second unit and the rotor still isn't directly under cap terminal but it is much closer then the first unit was.

I noticed the rough spot was a lot better at 2500 rpm but it's still slightly there.

I bought a modified reluctor from Rick ehrenberg and I have the reluctor in my shop.

I'm considering installing it at the 5 degree behind a tooth slot to move the rotor forward a little more.

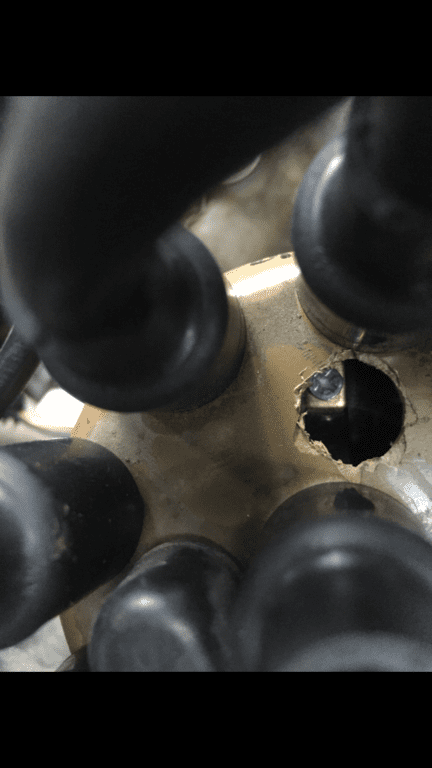

Below is a pic of where my rotor is with 18 degrees initial and 34 degrees total with an additional 12 degrees of timing added at idle for a total of 30 degrees of idle timing.

If you turn the picture upside down that hole is directly behind the number one cap terminal.

Is this close enough? Or could it be better?

Everything I've read says the rotor tip should be directly inline with the cap terminal and in the pic you can clearly see the rotor tip is not quite yet under the cap terminal but the edge of the rotor is just starting to come into contact with the cap terminal.

I'm trying to get eliminate this rough spot I get between 2500-3000 rpm and I believe this is the answer.

Going to attempt to keep it short and sweet.

91 Dodge w150 short bed 4x4 Truck.

300hp crate 360 Magnum, around 20-25k miles on engine.

Was running a Mopar distributor from FBO systems, kept having issues with the advance plate wobbling around, reluctor teeth smacking the pick up coil post.

Long story short I ditched that unit and bought a firecore 50 electronic vacuum advance unit.

First firecore unit ran extremely rough at 2500 rpm with initial timing at 18 degrees and total timing at 34 degrees and an additional 12 degrees from vacuum advance.

When I dis-connected the vacuum advance the (rough spot went away)

That led me to believe it was a rotor phasing issue.

So I drilled a 5/8 hole behind the number one tower on a spare distributor cap I had laying around and checked the rotor.

Sure enough it was out of phase.

Sent the unit back to firecore and firecore sent me a second unit.

Checked the phase on the second unit and the rotor still isn't directly under cap terminal but it is much closer then the first unit was.

I noticed the rough spot was a lot better at 2500 rpm but it's still slightly there.

I bought a modified reluctor from Rick ehrenberg and I have the reluctor in my shop.

I'm considering installing it at the 5 degree behind a tooth slot to move the rotor forward a little more.

Below is a pic of where my rotor is with 18 degrees initial and 34 degrees total with an additional 12 degrees of timing added at idle for a total of 30 degrees of idle timing.

If you turn the picture upside down that hole is directly behind the number one cap terminal.

Is this close enough? Or could it be better?

Everything I've read says the rotor tip should be directly inline with the cap terminal and in the pic you can clearly see the rotor tip is not quite yet under the cap terminal but the edge of the rotor is just starting to come into contact with the cap terminal.

I'm trying to get eliminate this rough spot I get between 2500-3000 rpm and I believe this is the answer.