I believe when that was printed, they were comparing the then current blocks to older engines like the early Hemi. In that respect, the later castings are indeed thin castings.This is bullshit....

View attachment 1716141120

Thin wall castings?

False. The later blocks have been found to be as thick or thicker than earlier blocks. The later blocks did have less nickel in them and were a little softer but they were still fine. Larry Shephard may have put out some good information but the "thin wall" stuff is wrong.

Why do you think you need to go .060 over? Where are you now? If you're at .030, why not take it .040? My '74 440 block is .040 over. Many 440 blocks have gone .060 without trouble, a 383 should too.

As stated before, a sonic check is the way to go. It will determine the thickness of the cylinders before you go any further.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Safe to bore a 383 60 over?

- Thread starter 4fortyDemon

- Start date

-

The "Thin wall" claim has been in many published releases from Ma Mopar. I don't know if it was printed in any factory service manual but in Mopar approved rebuild manuals, it has been printed there.

Mopar Muscle and Mopar Action magazine writers both have done stories where they sonic checked cylinder wall thicknesses on a variety of big blocks.

Both of them arrived at the same conclusion. Mopar Action's article elaborated a bit, stating that the false "thin wall" claim may have been a disguised warning due to a slightly inferior metal used in later blocks, a lower nickel content in the casting.

Mopar Muscle and Mopar Action magazine writers both have done stories where they sonic checked cylinder wall thicknesses on a variety of big blocks.

Both of them arrived at the same conclusion. Mopar Action's article elaborated a bit, stating that the false "thin wall" claim may have been a disguised warning due to a slightly inferior metal used in later blocks, a lower nickel content in the casting.

I know. It's a carry over from the earliest editions. That's what they were doing. Comparing to earlier engines. And in that case, they're right. I will say this. I have a 1974 225 slant 6 block. The thinnest I found on any of its cylinders was one of the non thrust sides. It came in at like .339". So it's certainly NOT a thin wall casting. lolThe "Thin wall" claim has been in many published releases from Ma Mopar. I don't know if it was printed in any factory service manual but in Mopar approved rebuild manuals, it has been printed there.

Mopar Muscle and Mopar Action magazine writers both have done stories where they sonic checked cylinder wall thicknesses on a variety of big blocks.

Both of them arrived at the same conclusion. Mopar Action's article elaborated a bit, stating that the false "thin wall" claim may have been a disguised warning due to a slightly inferior metal used in later blocks, a lower nickel content in the casting.

Yes, I was thinking bassackwards when I typed it..lol. I knew what I meant... lolI think you meant to say the pin sits lower on the early pistons. If it sits higher, that will lower the piston in the bore and lower compression.

Kern, I'm already at .040.This is bullshit....

View attachment 1716141120

Thin wall castings?

False. The later blocks have been found to be as thick or thicker than earlier blocks. The later blocks did have less nickel in them and were a little softer but they were still fine. Larry Shephard may have put out some good information but the "thin wall" stuff is wrong.

Why do you think you need to go .060 over? Where are you now? If you're at .030, why not take it .040? My '74 440 block is .040 over. Many 440 blocks have gone .060 without trouble, a 383 should too.

As stated before, a sonic check is the way to go. It will determine the thickness of the cylinders before you go any further.

Bores have .008 taper.. I really was surprised to hear it had that much. The pistons looked almost new , skirts had very little wear. Regardless... here's where it is.

That does make sense, last part of the article.The "Thin wall" claim has been in many published releases from Ma Mopar. I don't know if it was printed in any factory service manual but in Mopar approved rebuild manuals, it has been printed there.

Mopar Muscle and Mopar Action magazine writers both have done stories where they sonic checked cylinder wall thicknesses on a variety of big blocks.

Both of them arrived at the same conclusion. Mopar Action's article elaborated a bit, stating that the false "thin wall" claim may have been a disguised warning due to a slightly inferior metal used in later blocks, a lower nickel content in the casting.

@Kern Dog Perhaps he has a bad score? IDK!

I myself have a 400 low deck that has a really bad grove in a cylinder. IDK if it can be saved. It’s for a later date to discover.

If it needs a sleeve, it’s can do that. It’ll just be one sleeve. That’s expensive enough.

I myself have a 400 low deck that has a really bad grove in a cylinder. IDK if it can be saved. It’s for a later date to discover.

If it needs a sleeve, it’s can do that. It’ll just be one sleeve. That’s expensive enough.

Prior rebuilder may have just given it a quick hone and just went from there. A .008 taper isn’t huge though certainly not something I would let ride on a rebuild set for a performance upgrade.Kern, I'm already at .040.

Bores have .008 taper.. I really was surprised to hear it had that much. The pistons looked almost new , skirts had very little wear. Regardless... here's where it is.

rmchrgr

Skate And Destroy

The 383 block in the video below was bored .060" over. It was not sonic checked. Thiw is a 440 Source-based 438" stroker. Made 450hp, 475 lb. ft of torque. Does not overheat, guy drives the thing everywhere in all conditions. YRMV.

True, I could have thrown it together, but rings wouldn't have lasted but maybe 10k or so. Its gonna a street driven purpose car , but I'm gonna hammer on itPrior rebuilder may have just given it a quick hone and just went from there. A .008 taper isn’t huge though certainly not something I would let ride on a rebuild set for a performance upgrade.

Seth Jones

Well-Known Member

Would you be better off finding another block and re using your pistons? Pistons are sky high these days,I have a block I would give you if you were closer.

Like I said, the rebuilder before you probably just let what ever tapper it had ride. I have no doubt anybody, yourself included, would do the right thing for optimal return and longevity no matter what the purpose of the engine is built for.True, I could have thrown it together, but rings wouldn't have lasted but maybe 10k or so. Its gonna a street driven purpose car , but I'm gonna hammer on it

Thanks Seth. Really appreciate the offer.. real bummer is, I just sold a good 30 over 383 with 12 to 1 slugs in it. It only needed the crank cut from a spun rod. I could have used that... but.. here I am...lolWould you be better off finding another block and re using your pistons? Pistons are sky high these days,I have a block I would give you if you were closer.

Inertia

Well-Known Member

I just want to add some experience, after doing dozens and dozens of over the fender re-ring jobs.

As an apprentice, I spent 4 yrs doing what I was told.

I had an absolutely amazing mentor .

It was not uncommon in our shop, and thousands of shops across the nation, to de-glaze, hone and re-ring engines.

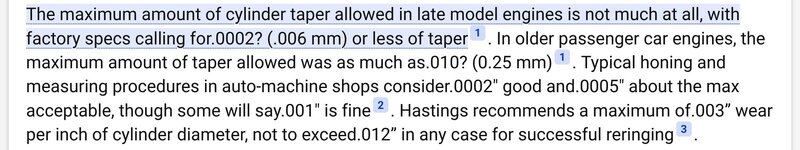

It was common, and Hastings recommendation for taper was something like 2 thou per inch diameter, max 12 thou, iirc.

Knowing what a race engine tolerance should be compared to a daily driver has proven to be different.

I guess, during my apprenticeship, I musta re-rung an engine a month, we serviced these vehicles for decades, I know some of these engines lasted decades with rings sealing fine, regular tune-ups with plugs read showed no oil burning issues.

It was common to do a valve grind at 60- 80k miles, and a re-ring at 100 - 120k miles, - no re-bore, taper up to 0.008 .

I know the theory, but hundreds of thousands vehicle were re-rung regularly with no issues.

So an engine only lasting 10k miles on a re-ring would likely be the exception to the rule on a street driven vehicle.

If it wasn't a successful procedure, it wouldn't have continued for decades .

A few we did were not successful, - but those were kinda expected, with the customer being warned before the effort .

I've read and woulda believed all the books, - if I hadn't done or authorized more than well over a hundred no re-bore re-rings with successful results.

Sorry, but it's the truth .

P.S. I kinda got a kick outta the 62 Pontiac (Canadian) 283 that was the very first re-ring I ever did, came in year after year running like a Swiss watch . lol

www.enginebuildermag.com

www.enginebuildermag.com

As an apprentice, I spent 4 yrs doing what I was told.

I had an absolutely amazing mentor .

It was not uncommon in our shop, and thousands of shops across the nation, to de-glaze, hone and re-ring engines.

It was common, and Hastings recommendation for taper was something like 2 thou per inch diameter, max 12 thou, iirc.

Knowing what a race engine tolerance should be compared to a daily driver has proven to be different.

I guess, during my apprenticeship, I musta re-rung an engine a month, we serviced these vehicles for decades, I know some of these engines lasted decades with rings sealing fine, regular tune-ups with plugs read showed no oil burning issues.

It was common to do a valve grind at 60- 80k miles, and a re-ring at 100 - 120k miles, - no re-bore, taper up to 0.008 .

I know the theory, but hundreds of thousands vehicle were re-rung regularly with no issues.

So an engine only lasting 10k miles on a re-ring would likely be the exception to the rule on a street driven vehicle.

If it wasn't a successful procedure, it wouldn't have continued for decades .

A few we did were not successful, - but those were kinda expected, with the customer being warned before the effort .

I've read and woulda believed all the books, - if I hadn't done or authorized more than well over a hundred no re-bore re-rings with successful results.

Sorry, but it's the truth .

P.S. I kinda got a kick outta the 62 Pontiac (Canadian) 283 that was the very first re-ring I ever did, came in year after year running like a Swiss watch . lol

Cylinder Bores-Machining To Sleeving - Engine Builder Magazine

Related Articles - Which Sedan Engines Are Least Accident Prone? - Stefan Rossi is Pursuing Peak Performance - America’s Best Engine Shops 2024 | Sunset Performance Engines The function of a cylinder bore is fairly simple yet quite demanding. The bore is nothing more than a cylindrical void...

Last edited:

Dcuda69

Well-Known Member

- Joined

- Jul 14, 2008

- Messages

- 261

- Reaction score

- 118

I have a 383 that's .060 over. I threw it together with crap laying around the shop hoping it would stay together for a couple years.Dingle ball hone,crap cast rings,knurled guides, 484/284 Mopar cam. Beat that thing for almost 20 years...lol. Didn't make a ton of power but never even flinched. Ran till the day I pulled it out. Still sitting in my back garage.

That's the same cam I'm using. What compression do you think you had that it didn't make a lot of power?I have a 383 that's .060 over. I threw it together with crap laying around the shop hoping it would stay together for a couple years.Dingle ball hone,crap cast rings,knurled guides, 484/284 Mopar cam. Beat that thing for almost 20 years...lol. Didn't make a ton of power but never even flinched. Ran till the day I pulled it out. Still sitting in my back garage.

I'm surprised I caught it. I'm the backwardest thinkin **** I know. lolYes, I was thinking bassackwards when I typed it..lol. I knew what I meant... lol

Lmao.. preaching to the choir there dude.. im glad it's a 383...dyslexia kicks in, I could be building a 044 for all I know.I'm surprised I caught it. I'm the backwardest thinkin **** I know. lol

Here's another option, I almost forgot. Send your pistons off to get coated by line 2 line. They'll fix you up.

It's abraidable it fits itself into the bore.

My forged pistons going in have .0015 clearance with the coating and will form itself to the bore as that coating gets broken in and holds oil very well

It's abraidable it fits itself into the bore.

My forged pistons going in have .0015 clearance with the coating and will form itself to the bore as that coating gets broken in and holds oil very well

harrisonm

Well-Known Member

@RustyRatRod, I was surprised when you said you could do a sonic test yourself. I understand what it is, but I have never seen one done. I always assumed it was a machine shop only test that would take thousands of dollars worth of specialized equipment that the average guy would not have. How can a guy do it by himself at home.

Never heard of that! Well, it's getting picked up from the machine shop on Fri. It's 60 over now with new pistons, block sonic checked, crank cut to 20 under, cam bearings r&r, hot tanked, rods resized with high strength bolts, all bearings and rings included from the machine shop. Quick turnaround. Looks like I'll have boat anchors lying around in the form of 40 over pistons...lol.Here's another option, I almost forgot. Send your pistons off to get coated by line 2 line. They'll fix you up.

It's abraidable it fits itself into the bore.

My forged pistons going in have .0015 clearance with the coating and will form itself to the bore as that coating gets broken in and holds oil very well

I'll update this weekend.

It's a hand held device with a probe that measures thickness.@RustyRatRod, I was surprised when you said you could do a sonic test yourself. I understand what it is, but I have never seen one done. I always assumed it was a machine shop only test that would take thousands of dollars worth of specialized equipment that the average guy would not have. How can a guy do it by himself at home.

Oh yeah that's quick turnaround. I wouldn't even worry about it being.060, just run it like she's brand new and have fun.Never heard of that! Well, it's getting picked up from the machine shop on Fri. It's 60 over now with new pistons, block sonic checked, crank cut to 20 under, cam bearings r&r, hot tanked, rods resized with high strength bolts, all bearings and rings included from the machine shop. Quick turnaround. Looks like I'll have boat anchors lying around in the form of 40 over pistons...lol.

I'll update this weekend.

I did a lot of reading and shopping around before I bought one. I held my breath when it got here, but it's a damn good one for the price. I've got about right at 400 bucks in it. IN order to do grey cast iron correctly, you need a bigger probe than what they come with and that's an extra expense. I was pleasantly surprised by the accuracy. I have a friend at a shop with one that cost about two grand and mine seems to have the same accuracy. He was pretty impressed. Here are a few pictures. Scamp had to ham it up for the camera. lol@RustyRatRod, I was surprised when you said you could do a sonic test yourself. I understand what it is, but I have never seen one done. I always assumed it was a machine shop only test that would take thousands of dollars worth of specialized equipment that the average guy would not have. How can a guy do it by himself at home.

Last edited:

You can see how much bigger the large probe is. That's important too, because believe it or not it makes a pretty big difference in the readings. Also, We looked and looked and can find no evidence of where it's made. The ad said it was "Made in USA" and we both feel like the quality is there, but there's no proof and since it seems to be generic in nature, it's probably not. It works well enough for measuring cylinder wall thickness, though and it does it really accurately.

-